Vine climbing net facilitating pruning and preparing method for vine climbing net

A vine-climbing net and vine-climbing technology, applied in the field of vine-climbing nets, can solve the problems of high plant vines, inconvenient pruning, inability to effectively prune, etc., and achieve the effect of improving strength and facilitating pruning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation method of climbing rattan net, comprises the steps:

[0018] (1) Mix 10 parts of ABS, 1 part of nanobismuth powder, 1 part of talc powder, 5 parts of PC, 0.5 parts of sodium sulfite, 0.5 parts of organosiloxane, 0.5 parts of iron powder, and 0.5 parts of polyphenylene ether ketone, and heat to 250 Celsius and kept for 1h, then extruded into the mold cavity, the mold cavity is a cube shape, the thickness of the mold cavity is 1cm, and the above parts are parts by weight;

[0019] (2) Cooling and molding, mold opening to obtain the primary product, the primary product is sheared by a cutter, and uniformly arranged small holes are formed on the primary product;

[0020] (3) Fix the two ends of the diagonal line of the initial product, and stretch the product to the outside of the diagonal line so that the small holes are stretched to form larger holes to form climbing rattan net products;

[0021] (4) The back of the climbing rattan net product is attached...

Embodiment 2

[0023] (1) Mix 15 parts of ABS, 2 parts of nanobismuth powder, 2 parts of talc powder, 7 parts of PC, 1 part of sodium sulfite, 1 part of organosiloxane, 1 part of iron powder, and 1 part of polyphenylene ether ketone, then heat to 280 Celsius and kept for 2h, then extruded into the mold cavity, the mold cavity is a cube shape, the thickness of the mold cavity is 2cm, and the above parts are parts by weight;

[0024] (2) Cooling and molding, mold opening to obtain the primary product, the primary product is sheared by a cutter, and uniformly arranged small holes are formed on the primary product;

[0025] (3) Fix the two ends of the diagonal line of the initial product, and stretch the product to the outside of the diagonal line so that the small holes are stretched to form larger holes to form climbing rattan net products;

[0026] (4) The back of the climbing rattan net product is attached to the stepped structure.

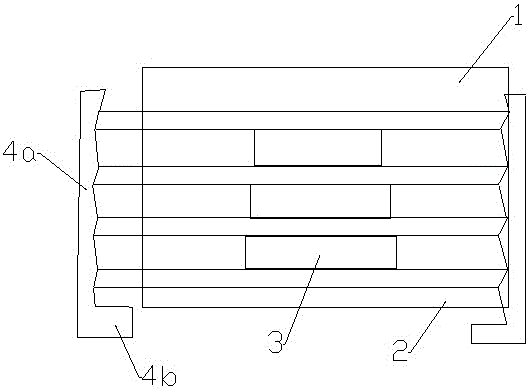

[0027] A climbing vine net for convenient pruning, compri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com