Washer comprising automatic dosing unit

A technology of dosing and scrubbers, applied in the field of scrubbers, can solve the problems that the dosing process cannot be performed, the cleaning agent cannot be delivered to the container, etc., and achieve the effect of reliable liquid level measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

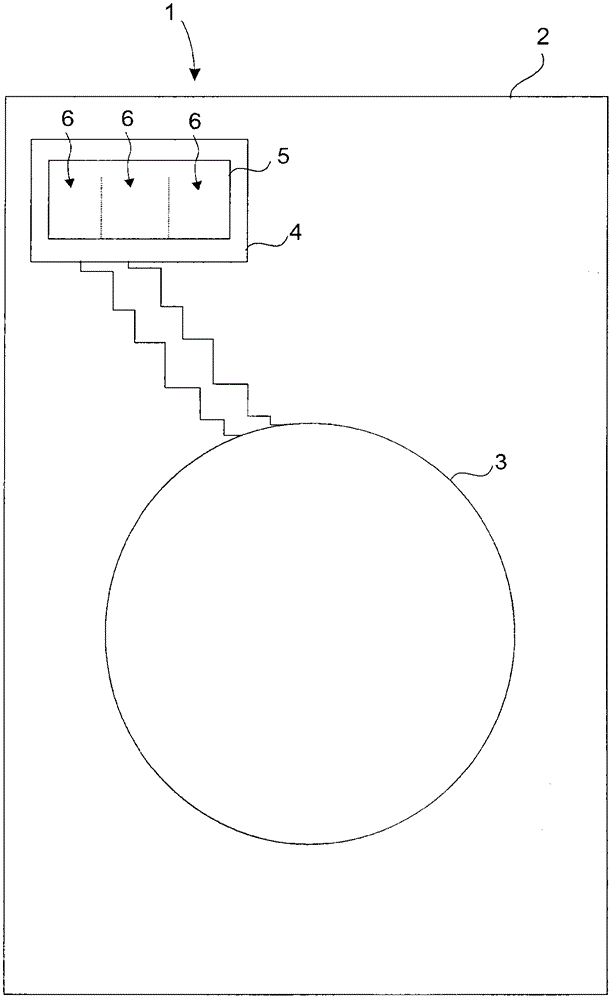

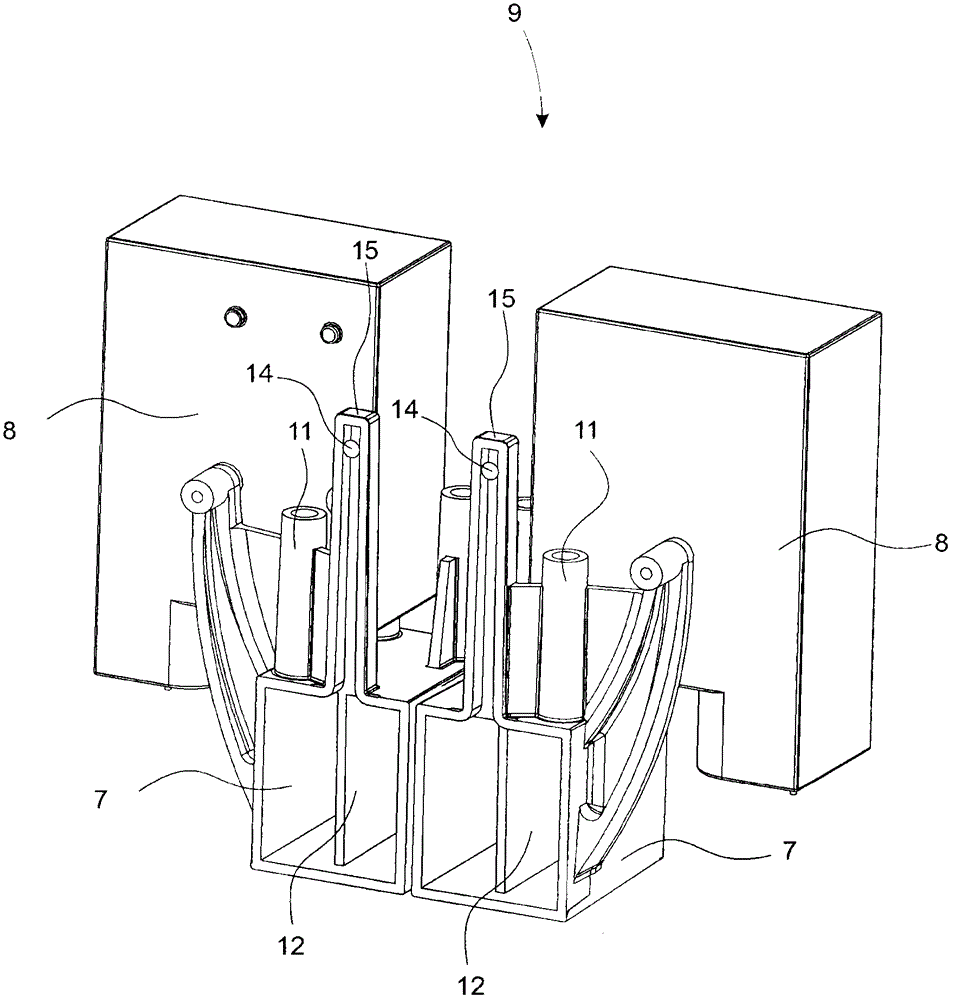

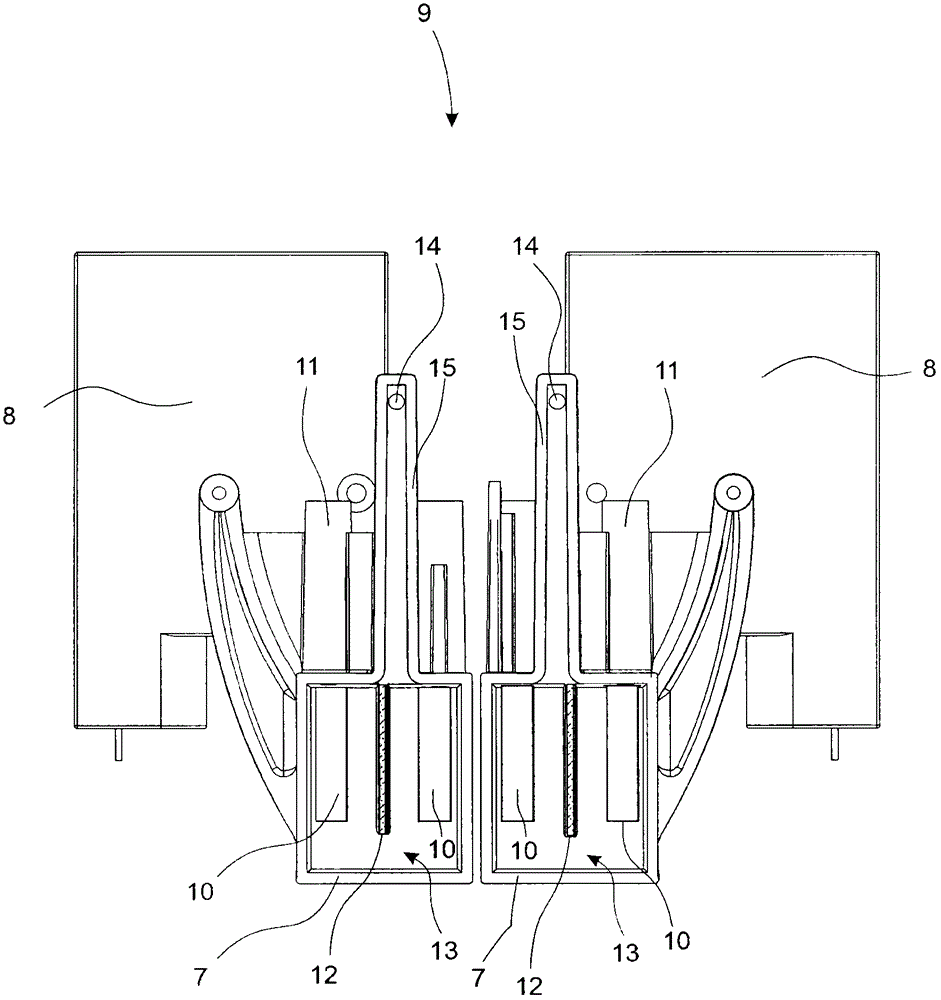

[0037] The scrubber (1) comprises a main body (2); a tub (3) arranged in the main body (2), in which a washing-drying process is performed; The outer surface extends into the main body (2); the dispenser (5), which is arranged inside the housing (4) and which has a plurality of partitions (6) for storing cleaning agent; the dosing of the adjacent housing (4) A unit (9), with a flow connection between the housing (4) and a dosing unit (9), the dosing unit (9) has at least one dosing container (7) and at least one dosing pump (8), in The cleaning agent filled into the dispenser (5) is stored in the dosing container (7) for dosing, the dosing pump (8) is arranged on the dosing container (7), and the dosing pump (8) draws in the dosing container (7) and enable the cleaning agent to be delivered to the housing (4) for delivery to the barrel (3); and at least two pins (10) positioned in the dose container (7) and used to determine the type and bit.

[0038] In the scrubber (1), a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com