Mining vehicle and method for energy supply thereof

A technology for energy supply and vehicles, applied in vehicle energy storage, vehicle components, electric vehicles, etc., can solve problems such as occupying a lot of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

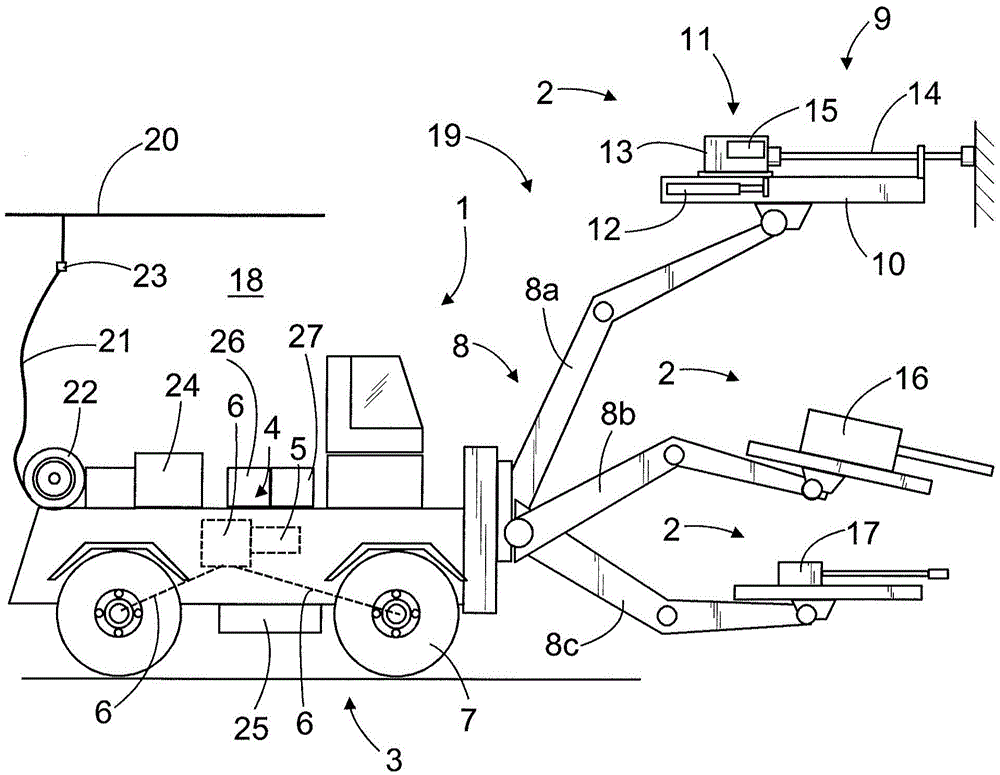

[0015] figure 1 A rock drilling rig is shown as an example of a mining vehicle 1 equipped with one or more mining implements 2 . The rock drilling rig comprises a carriage 3 which can be moved by means of a drive device 4 . The drive device 4 comprises one or more drive motors 5 and one or more transmissions 6 for transmitting drive power to one or more wheels 7 . The drive power transmission may comprise a mechanical gear system and mechanical power transmission members, or, alternatively, the drive power transmission may be hydraulic or electric. One or more drill booms 8 may be arranged on the carrier 3 and the drill booms 8 may be equipped with the mining work equipment 2 . exist figure 1 In the embodiment shown in , the first drilling arm 8a is a drilling arm, at the outermost end of which there is a rock drilling unit 9 comprising a feed beam 10, by means of which a rock drilling machine 11 can be The feeding device 12 moves along the feed beam 10 . The rock drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com