Ultrasonic transverse and longitudinal section element-separating detection method for stainless steel and nickel-based steel weld joint

A technology of ultrasonic testing and stainless steel, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, and can solve problems such as difficulty in ultrasonic testing of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0039] A kind of stainless steel, nickel base steel welding seam ultrasonic vertical and horizontal plane sub-element detection method of the present invention, comprises the following steps:

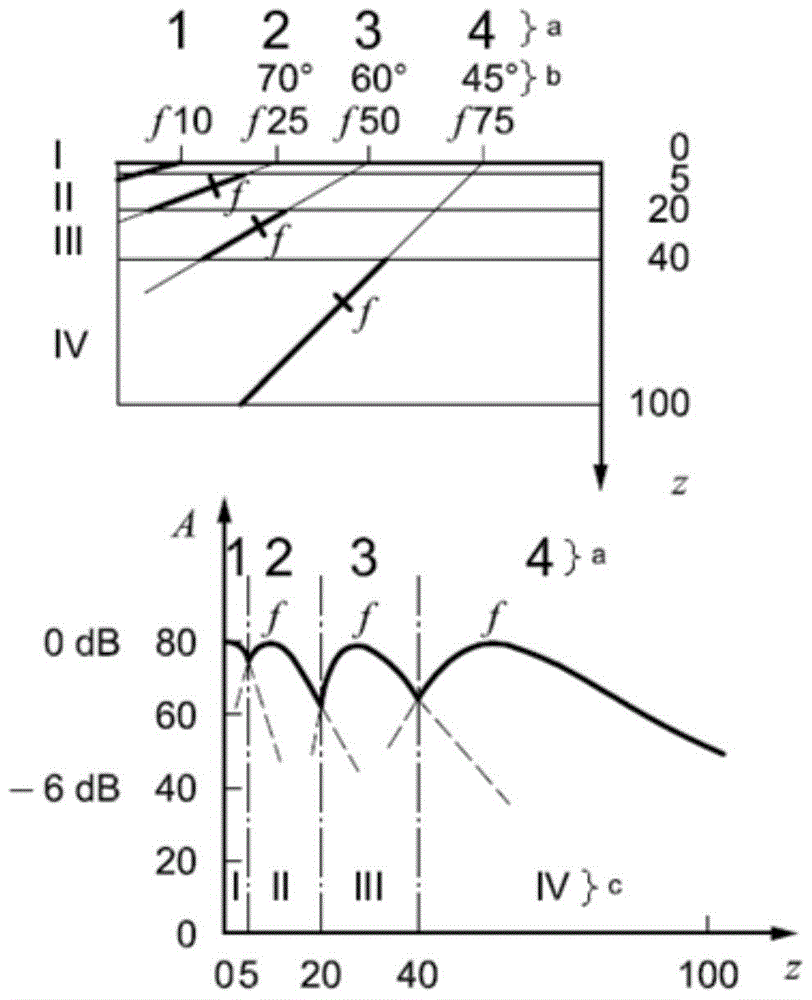

[0040] Step S1, see figure 1 , in the base metal of stainless steel and nickel-based steel, establish a series of standard reflectors with different depths that do not interfere with each other for ultrasonic testing (long horizontal holes Φ3*40mm are optional), and use this to establish the DAC curve. It should be noted that the double When the crystal angle probe detects standard reflectors, the peak wave drop is not greater than 6dB;

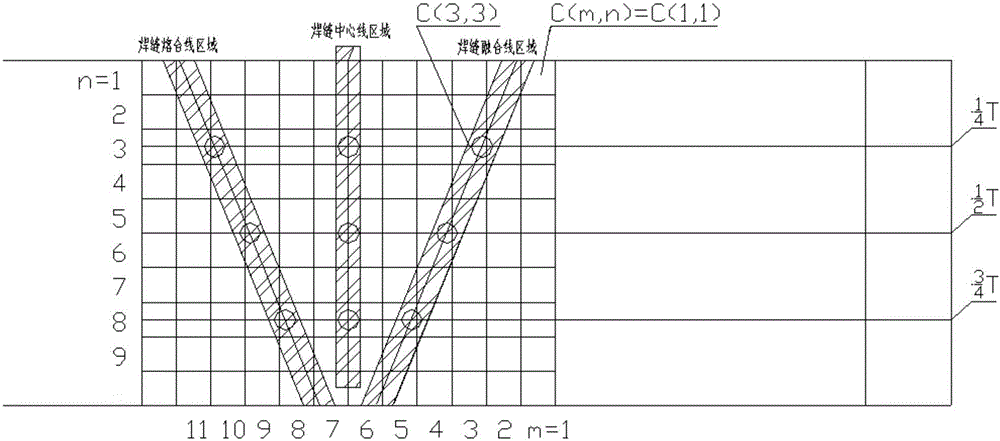

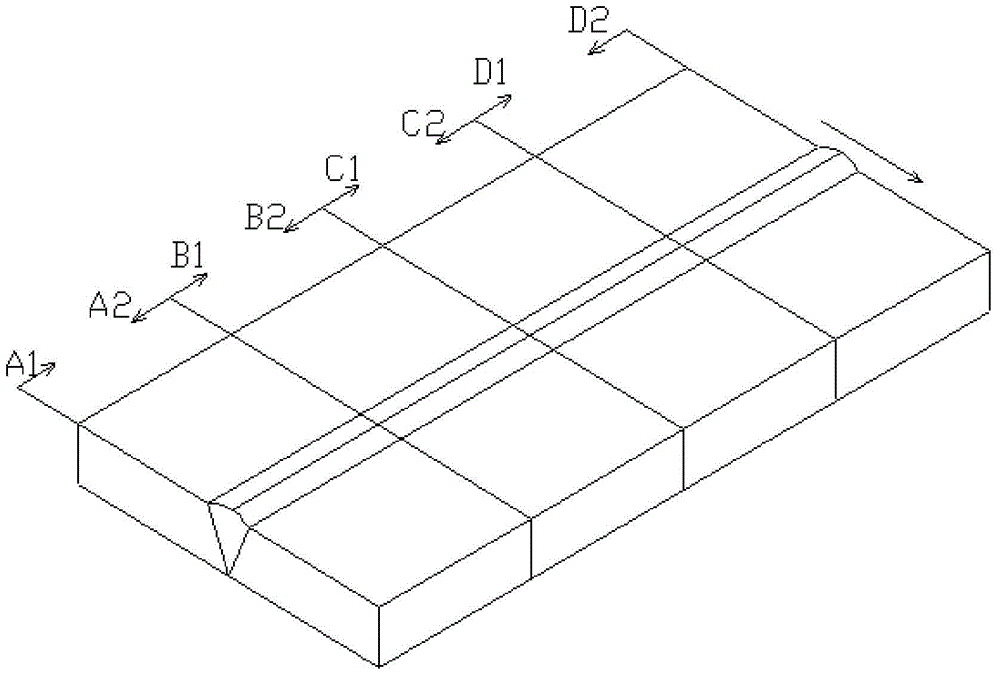

[0041] Step S2, see figure 2 , make the same welding seam comparison test plate as the on-site welding process. Gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com