Drive assembly detection device used for gear and rack lifting mechanism

A technology of driving components and detection devices, which is applied in the direction of machine gear/transmission mechanism testing, etc., and can solve problems such as the inability to detect the functionality of driving components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

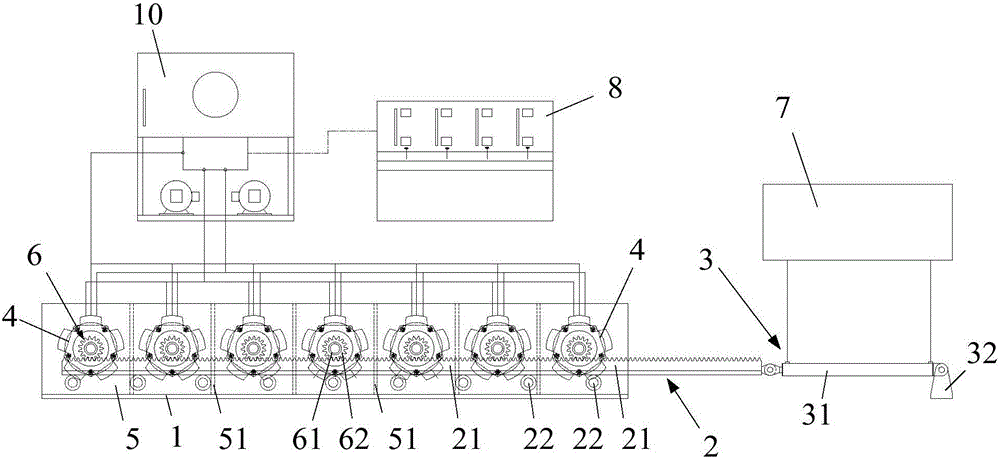

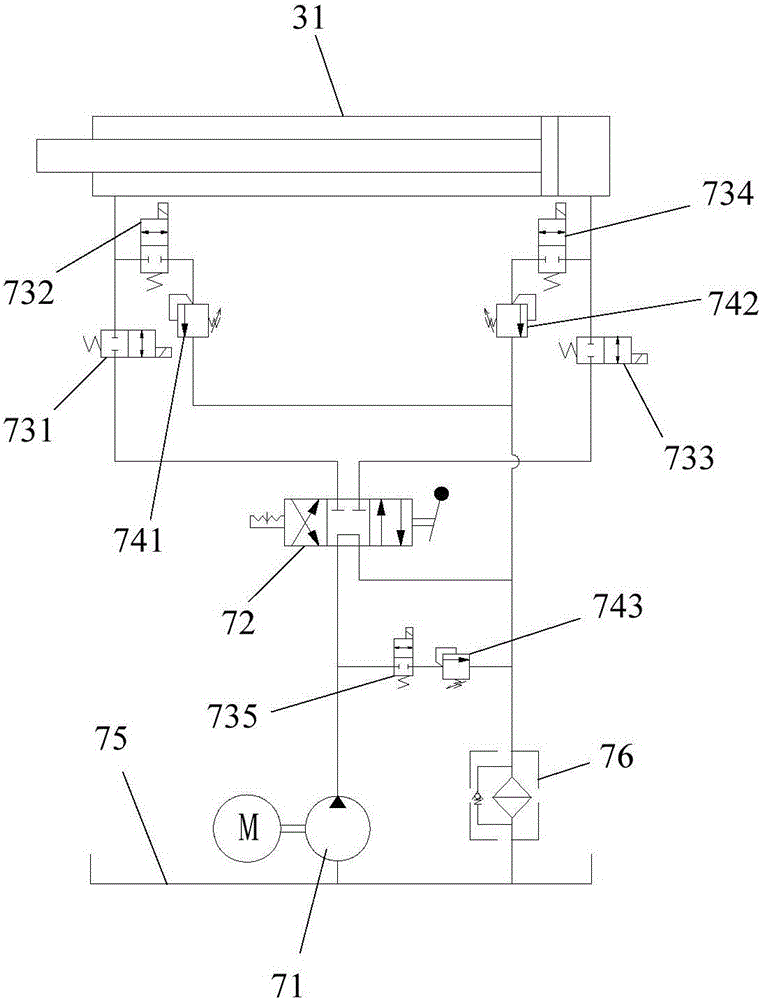

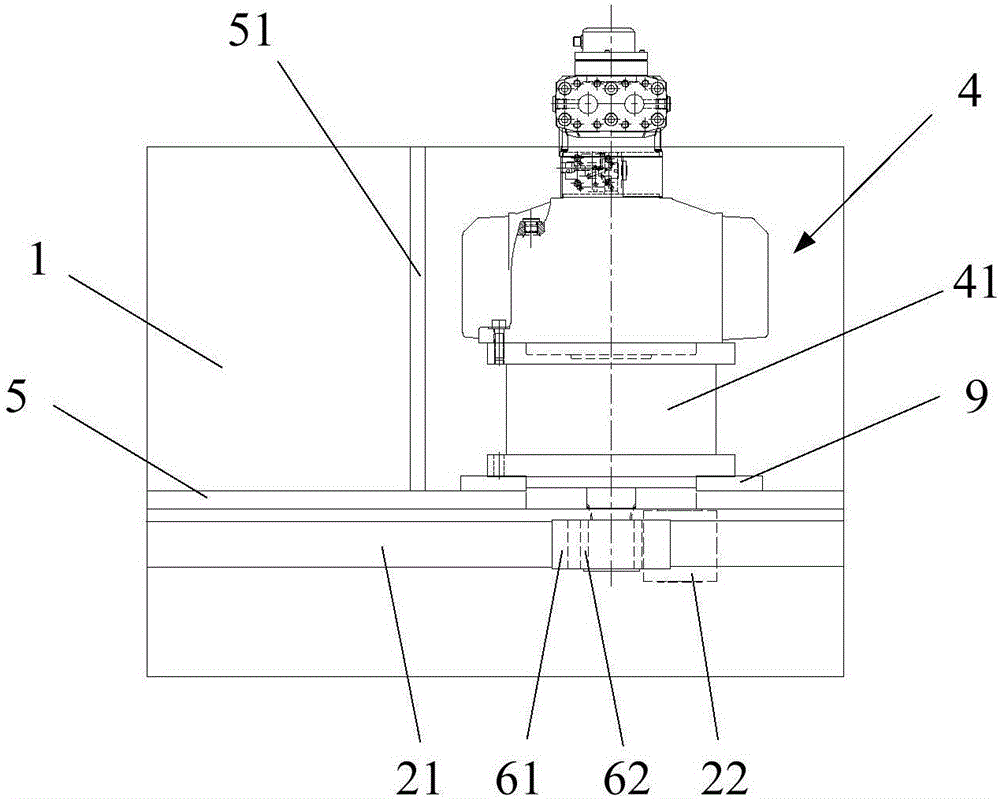

[0030] An embodiment of the present invention provides a driving component detection device for a rack and pinion lifting mechanism, such as figure 1 As shown, the detection device includes: a base plate 1, a rack assembly 2, a load simulation assembly 3, a mounting bracket 5 for installing the driving assembly 4 to be tested and a gear assembly 6 matched with the rack assembly 2, and the mounting bracket 5 is installed vertically on the base plate 1, the rack assembly 2 is slidably installed on the base plate 1 at the position corresponding to the mounting bracket 5, the rack assembly 2 and the mounting bracket 5 are arranged parallel to each other, the rack assembly 2 is meshed with the gear assembly 6, and the test During installation, the drive assembly 4 to be tested is installed on the mounting bracket 5, and the drive assembly 4 to be tested and the gear assembly 6 are located on opposite sides of the mounting bracket 5 respectively, and the gear assembly 6 is set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com