exhaust gas turbocharger

An exhaust gas turbine and supercharger technology, which is applied in gas turbine installations, machines/engines, engine functions, etc., can solve the problems of reducing the efficiency of exhaust gas turbochargers, reducing turbine efficiency, etc., to improve response behavior, reduce noise, use Life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

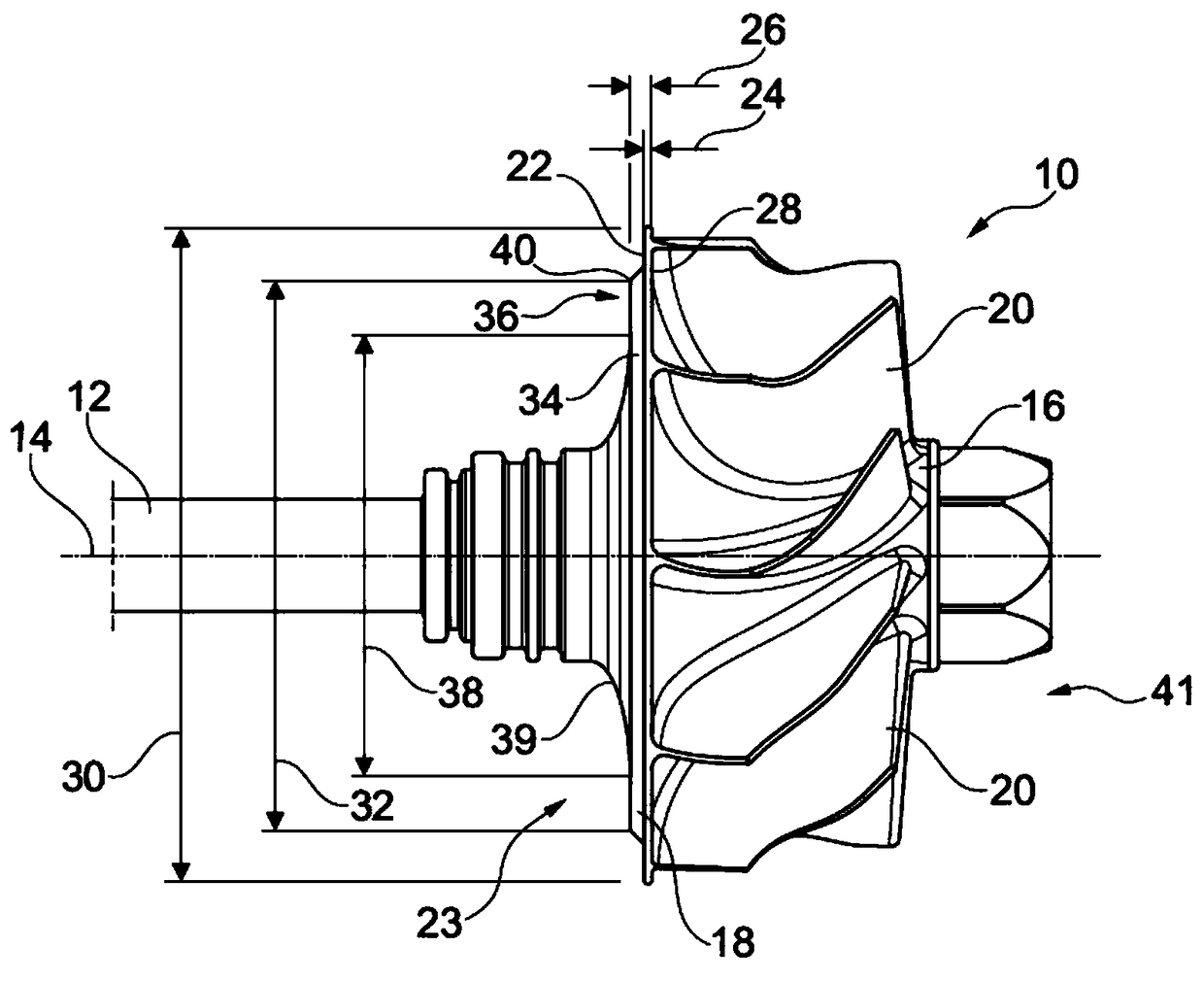

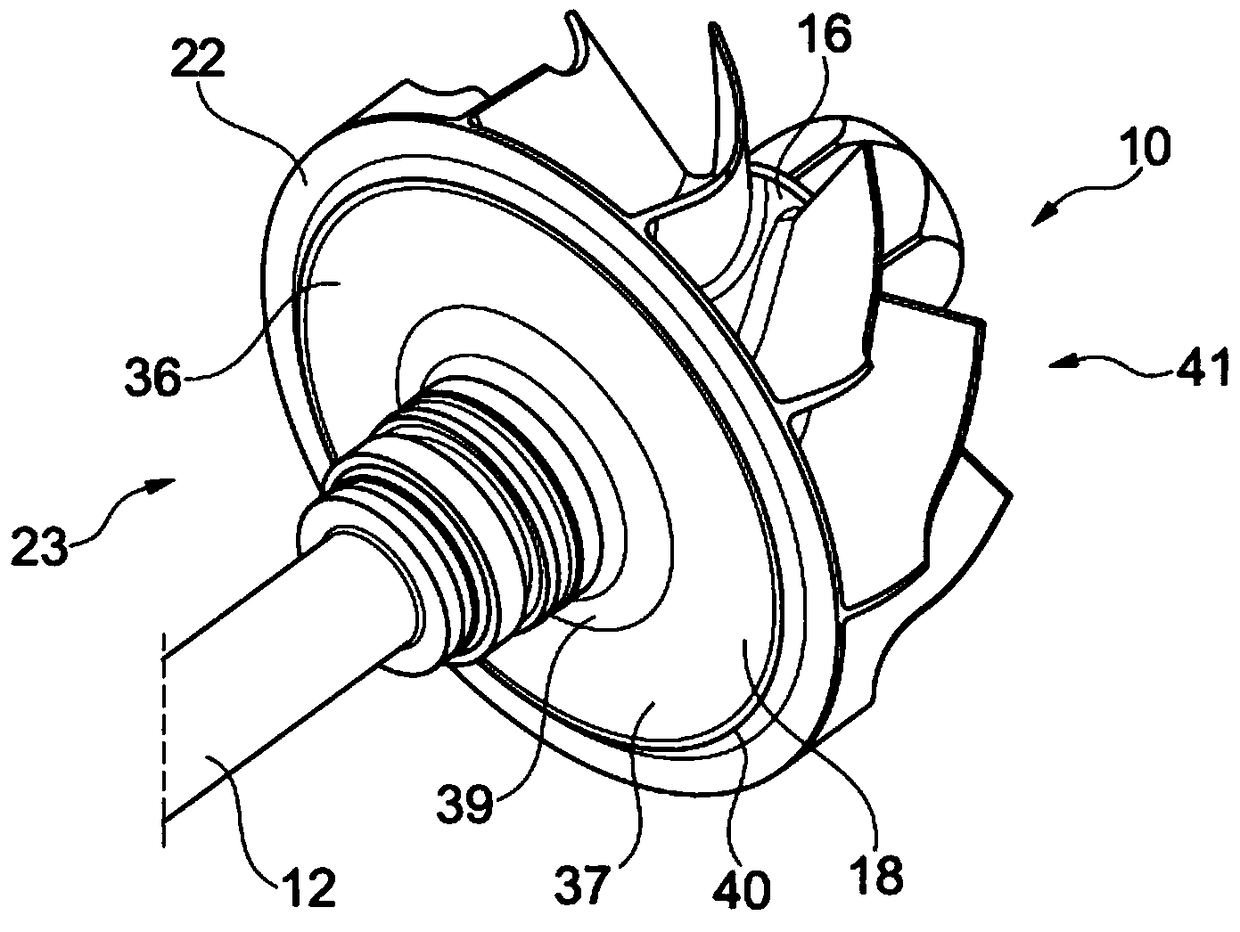

[0029] A turbocharger (not shown) comprises a turbine 10 fixedly connected in rotation via a shaft 12 to a compressor wheel (not shown) mounted rotatably about an axis of rotation 14 and driven by exhaust gas vapor . The turbine 10 has a hub 16 , a wheel backing 18 , and a plurality of blades 20 extending radially outward from the hub 16 on a flow side 41 and axially from the wheel backing 18 . Thus, the blades 20 extend in the region where the hub 16 and the wheel backing 18 turn. In this respect, the blades 20 are curved in such a way that flow energy from the exhaust gas vapor can be converted into a rotational movement of the turbine 10 caused by the blades 20 . As a result, the turbine 10 and thus also the compressor wheel of the exhaust gas turbocharger can be driven by the exhaust gas vapor. No blades 20 are arranged on the rear side 23 of the wheel backing 18 facing away from the flow, so that the rear side 23 has a low resistance to flow.

[0030] In order to reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com