Clothing wrinkle-removing method for clothing dryer and clothing dryer

A technology for clothes dryers and clothes, which is applied in the field of clothes dryers, can solve the problems of poor wrinkle removal effect and limited clothes wrinkle removal effect, and achieve the effects of saving time, good wrinkle removal effect, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

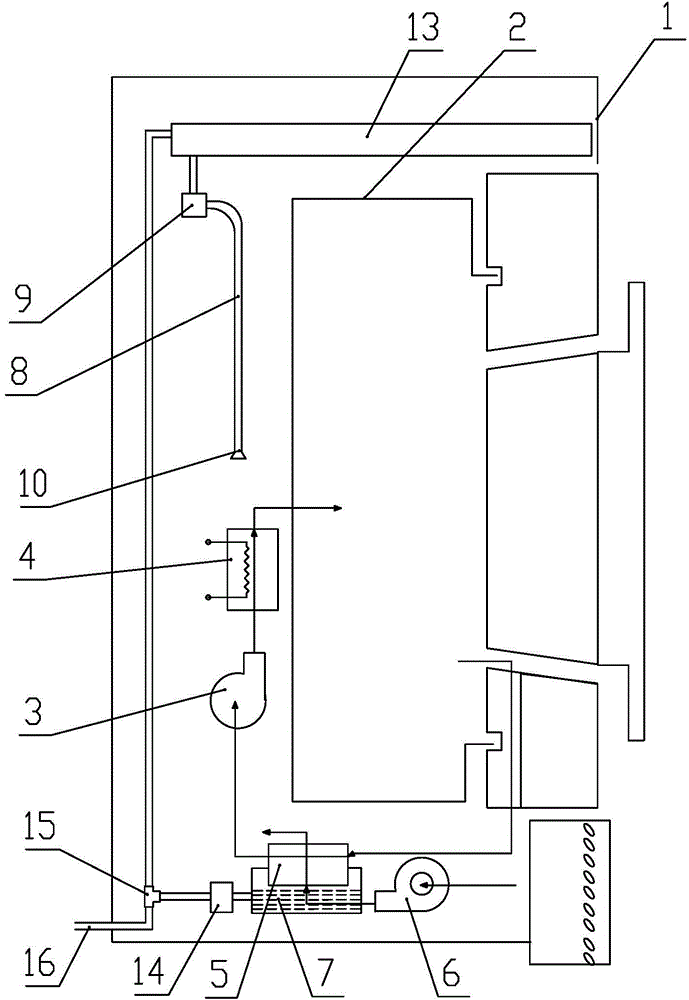

[0030] This embodiment provides a condensation dryer with wrinkle removal function, such as figure 1 As shown, it includes a box body 1, a control panel is arranged outside the box body 1, a drum 2 and a circulating air duct communicating with the drum 2 are arranged in the box body 1, and a circulating fan 3, a heat exchanger and a circulating air duct are arranged in the circulating air duct. Heater 4. The circulation fan 3 is used to circulate the air in the drum 2 and the circulation air duct. The heater 4 is used to heat the circulating air. The heat exchanger includes a condenser 5 and a fan 6, and a water tank 7 is arranged below the condenser 5.

[0031] A spraying device 10 is arranged above the heater 4, and the spraying device 10 is connected to a water inlet pipe 8, and a water inlet valve 9 is arranged on the water inlet pipe 8, and the opening and closing of the water inlet valve 9 is controlled by a control panel. The spray device 10 can spray water mist towa...

Embodiment 2

[0042] This embodiment provides a condensation-type clothes dryer with a wrinkle-removing function. Its structure is basically the same as that of Embodiment 1. The circulation air duct is provided with a circulation fan, a heat exchanger and a heater in the circulation air duct. The heat exchanger includes a condenser and a fan, and a water tank is arranged under the condenser. A spraying device is arranged above the heater, the spraying device is connected with a water inlet pipe, and a water inlet valve is arranged on the water inlet pipe, and the opening and closing of the water inlet valve is controlled by the control panel.

[0043] The difference is that in this embodiment, the predetermined spraying time of the spraying stage can be set manually, or can also be determined by the clothes dryer according to the amount of clothes in the drum. The specific determination method is:

[0044] Step 1. There are multiple weight ranges pre-stored in the control panel, and each...

Embodiment 3

[0049] This embodiment provides a condensation dryer with wrinkle removal function, such as image 3 As shown, its structure is basically the same as that of Embodiment 1, including a box body 1, a control panel is arranged outside the box body 1, a drum 2 and a circulating air duct communicating with the drum 2 are arranged in the box body 1, and a circulating air duct is arranged in the circulating air duct Circulation fan 3, heat exchanger and heater 4. The heat exchanger includes a condenser 5 and a fan 6, and a water tank 7 is arranged below the condenser 5. A spraying device 10 is arranged above the heater 4, and the spraying device 10 is connected to a water inlet pipe 8, and a water inlet valve 9 is arranged on the water inlet pipe 8, and the opening and closing of the water inlet valve 9 is controlled by a control panel.

[0050] The difference is that the clothes dryer in this embodiment also has a water box 13 . The water tank 7 is connected with a drain pump 14 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com