A method for preparing nanometer ba(fe0.5nb0.5)o3 powder by microwave hydrothermal method

A microwave hydrothermal method and nano-technology, which is applied in the field of wet chemical method to prepare nano-powder, can solve the problems of large particle size, limited ceramic performance, powder agglomeration, etc., and achieves improved dielectric properties and shortened reaction time , good shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

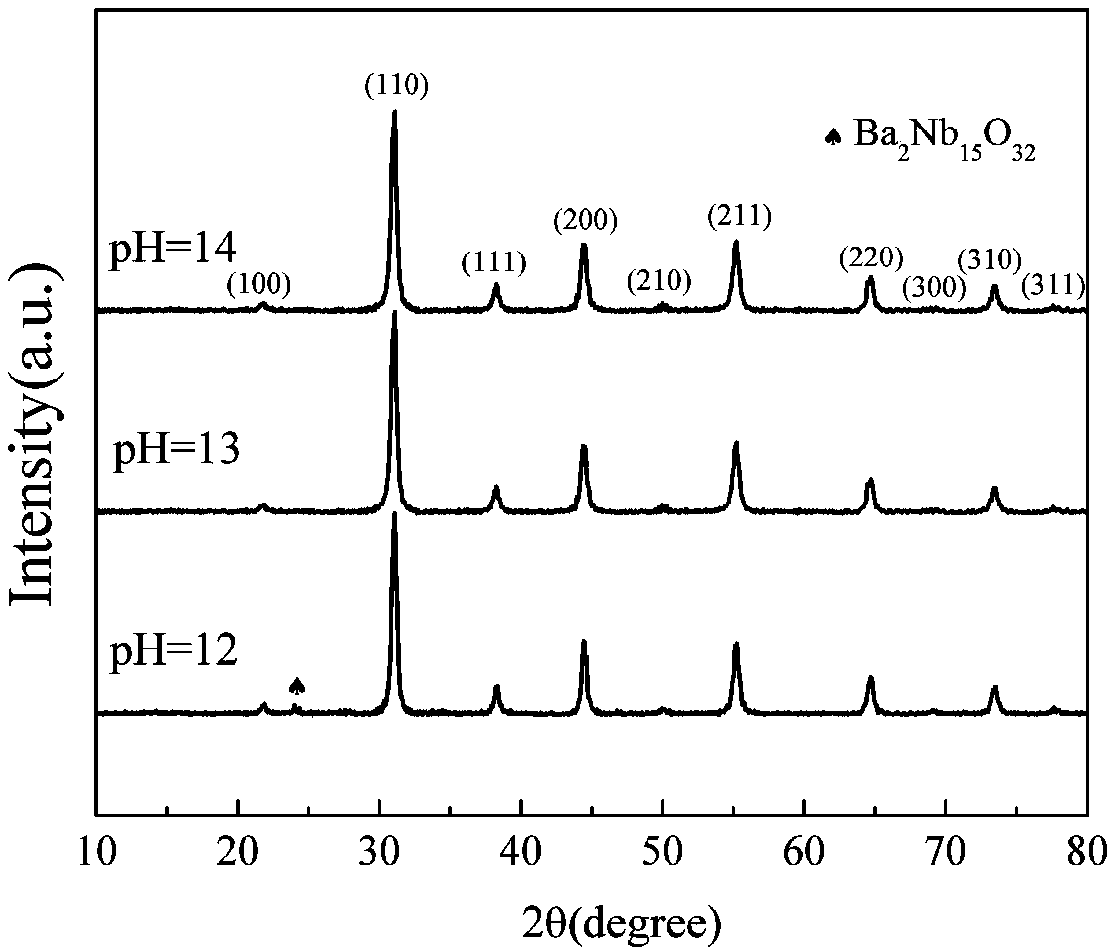

[0031] A kind of microwave hydrothermal method of the present invention prepares nanometer Ba(Fe 0.5 Nb 0.5 )O 3 The method of powder, comprises the steps,

[0032] (1) Prepare a dilute hydrochloric acid solution with a concentration of 1 mol / L and a NaOH solution with a concentration of 5 mol / L in advance for future use. According to Ba(Fe 0.5 Nb 0.5 )O 3 The stoichiometric ratio of 2:1:1 accurately weighs Ba(NO 3 ) 2 , Fe(NO 3 ) 3 9H 2 O, NbCl 5 .

[0033] (2) Quickly weigh NbCl 5 , dissolve it in the dilute hydrochloric acid prepared in advance, seal it with plastic wrap, and place it in a magnetic stirrer to stir for 10h to make the NbCl 5 Dissolve completely in hydrochloric acid solution to give NbCl 5 hydrochloric acid solution, Nb 5+ The ion concentration is 0.06mol / L.

[0034] (3) Ba(NO 3 ) 2 Added in deionized water, stirred until completely dissolved to obtain Ba(NO 3 ) 2 Aqueous solution, Ba(NO3 ) 2 The concentration of the aqueous solution is 0...

Embodiment 2

[0040] A kind of microwave hydrothermal method of the present invention prepares nanometer Ba(Fe 0.5 Nb 0.5 )O 3 The method of powder, comprises the steps,

[0041] (1) Prepare a dilute hydrochloric acid solution with a concentration of 2 mol / L and a NaOH solution with a concentration of 8 mol / L in advance for future use. According to Ba(Fe 0.5 Nb 0.5 )O 3 The stoichiometric ratio of 2:1:1 accurately weighs Ba(NO 3 ) 2 , Fe(NO 3 ) 3 9H 2 O, NbCl 5 .

[0042] (2) Quickly weigh NbCl 5 , dissolve it in the dilute hydrochloric acid prepared in advance, seal it with plastic wrap, and place it in a magnetic stirrer to stir for 12 hours to make NbCl 5 Dissolve completely in hydrochloric acid solution to give NbCl 5 hydrochloric acid solution, Nb 5+ The ion concentration is 0.07mol / L.

[0043] (3) Ba(NO 3 ) 2 Add deionized water, stir until completely dissolved, and get Ba(NO 3 ) 2 Aqueous solution, Ba(NO 3 ) 2 The concentration of the aqueous solution is 0.07mol...

Embodiment 3

[0049] A kind of microwave hydrothermal method of the present invention prepares nanometer Ba(Fe 0.5 Nb 0.5 )O 3 The method of powder, comprises the steps,

[0050] (1) Prepare a dilute hydrochloric acid solution with a concentration of 3 mol / L and a NaOH solution with a concentration of 10 mol / L in advance for future use. According to Ba(Fe 0.5 Nb 0.5 )O 3 The stoichiometric ratio of 2:1:1 accurately weighs Ba(NO 3 ) 2 , Fe(NO 3 ) 3 9H 2 O, NbCl 5 .

[0051] (2) Quickly weigh NbCl 5 , dissolve it in the dilute hydrochloric acid prepared in advance, seal it with plastic wrap, and place it in a magnetic stirrer to stir for 15 hours to make the NbCl 5 Dissolve completely in hydrochloric acid solution to give NbCl 5 hydrochloric acid solution, Nb 5+ The ion concentration is 0.08mol / L.

[0052] (3) Ba(NO 3 ) 2 Add deionized water, stir until completely dissolved, and get Ba(NO 3 ) 2 Aqueous solution, Ba(NO 3 ) 2 The concentration of the aqueous solution is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com