Cooling air cooling system of shock cooling section of glass tempering furnace

A cooling air and cooling system technology, applied in glass tempering, glass production, glass manufacturing equipment, etc., can solve problems such as differences in tempered glass performance, affecting cooling effect, temperature rise of fan air intake, etc., to improve yield, guarantee The effect of improving performance and component strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

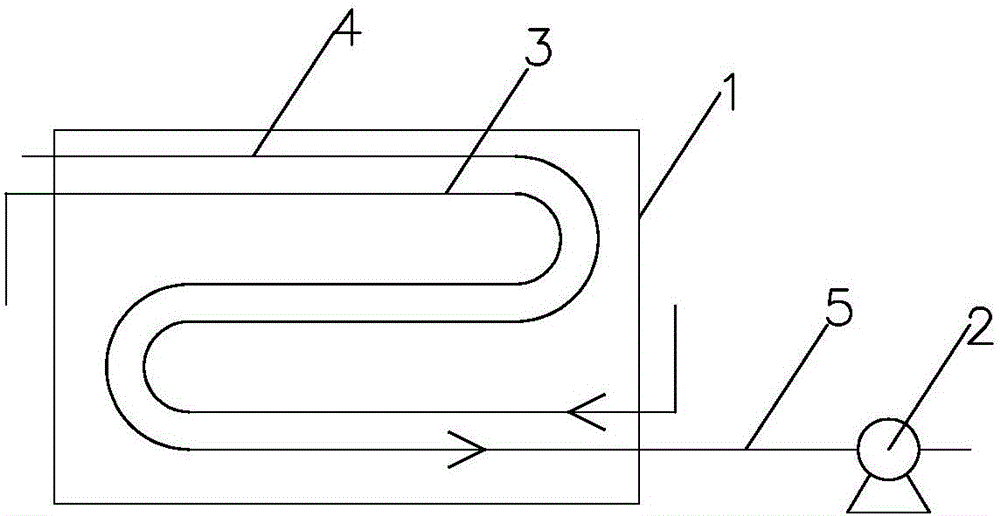

[0022] Such as figure 1 As shown, a cooling system for cooling air in the quenching section of a glass tempering furnace includes a quenching section fan 2 and a cooling device that provides a source of cooling air for the quenching section fan 2, and the cooling device and the quenching section The section fan 2 is connected through a ventilation pipe 5, and the quenching section fan 2 and the cooling system are both arranged in the basement.

[0023] Specifically, the cooling device is composed of several stages of heat exchangers 1 connected in series. The heat exchanger 1 includes an air pipe 3 and a cooling pipe 4 , the cooling pipe 4 is arranged around the air pipe 3 , and the flow direction of the cooling liquid in the cooling pipe 4 is opposite to that of the air in the air pipe 3 . The cooling liquid is cooling water or cooling oil, and this embodiment takes cooling water as an example.

[0024] The working principle is as follows, the cooling water is used to cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com