Bicycle assisting force system adopting middle-axis torque sensor

A power assist system and sensor technology, applied in bicycle accessories, bicycle sensors, force/torque/power measuring instruments, etc., can solve problems such as lack of torque sensors and hinder market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

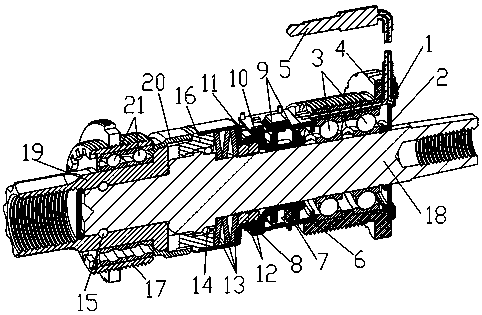

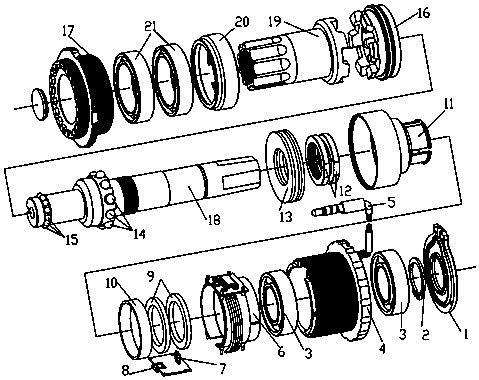

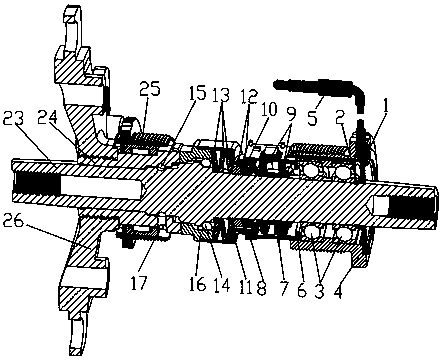

[0061] Such as figure 1 and figure 2 As shown, the present invention adopts the bicycle power assist system of the axis moment sensor and includes two kinds of structural schemes:

[0062] The first structural solution is: the bicycle power assist system includes a central axis torque sensor, and the central axis torque sensor includes: an end cover 1, an elastic snap ring 2, a ball bearing 3, a nylon shaft bowl 4, a connecting wire 5, and a PCB board support 6 , Displacement Hall IC7, Speed Hall IC8, Unipolar Magnetic Ring 9, Multipolar Magnetic Ring 10, Magnetic Ring Bracket 11, Nut 12, Disc Spring Set 13, Steel Ball 14, Limiting Steel Ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com