Light-cured 3D printer

A 3D printer and light-curing technology, applied in the field of 3D printing, can solve the problems of large shape, solidified layer error, and large shape of light-cured 3D printers, and achieve the effects of high printing accuracy, portability and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

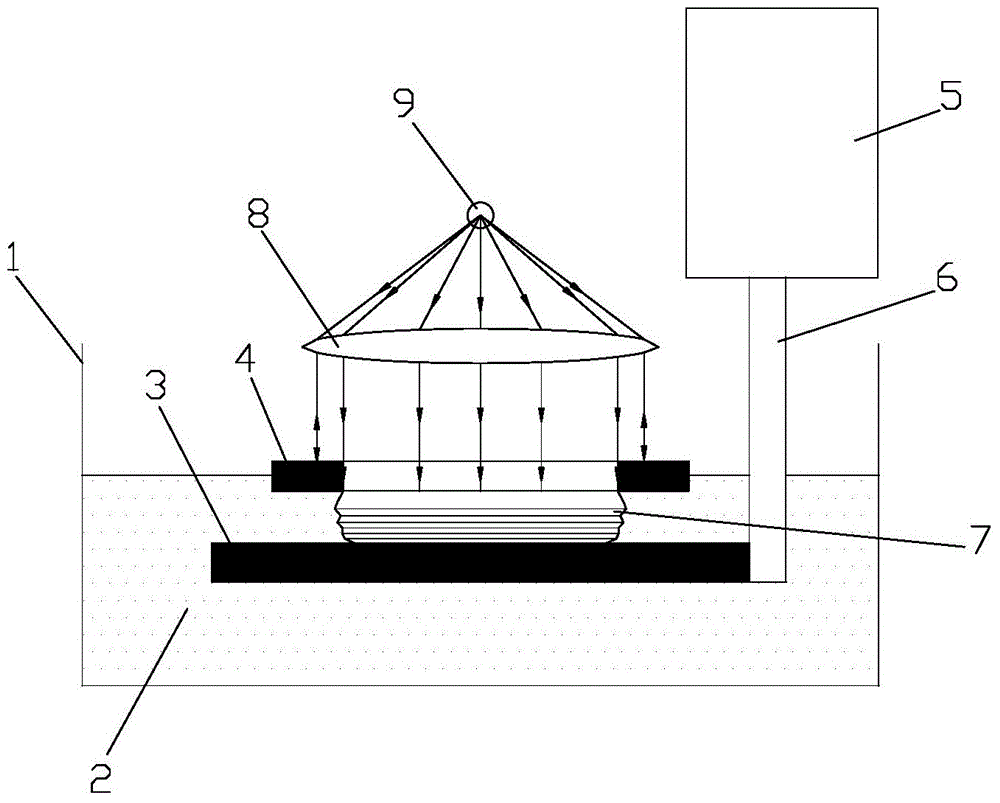

[0027] Such as Figure 1-4 As shown, one embodiment of the present invention provides a light-curing 3D printer, including a tank 1 containing a liquid photosensitive resin 2, a carrier plate 3, a driving mechanism 5, a beam generating assembly, and a liquid crystal screen 4; the tank 1 It needs to be fixed, and it is better to keep it horizontal to prevent the liquid photosensitive resin 2 from flowing out; the carrier plate 3 is used to accept the cured photosensitive resin 7 (the cured photosensitive resin 7 is actually the printed part of the target printing part); the driving mechanism 5 is connected to the carrier plate 3 through a connecting rod 6, and the carrier plate 3 is driven to move through the connecting rod 6; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com