Machining technology of antitheft nut of 35KV outdoor upper rod platform support

A platform bracket and processing technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve problems such as damage, cable terminal damage, power loss, etc., to achieve a wide range of applications, reduce theft rate, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

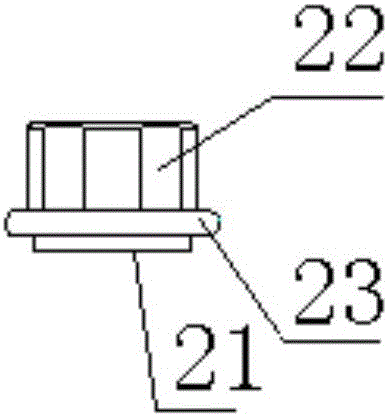

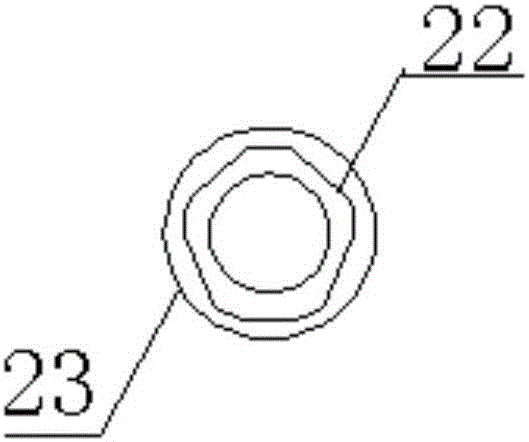

[0019] see figure 1 and figure 2 , the anti-theft nut comprises a hollow cylindrical inner core 21, a pentagonal overcoat 22 and a flange 23, the pentagonal overcoat 22 and the flange 23 are respectively fixed on the outside of the cylindrical inner core 21, and the top of the flange 23 is connected to the pentagonal overcoat 22 The bottom ends are fixed together, the anti-theft nut is integrally formed, and the inner wall of the anti-theft nut is provided with threads. The thread adopts the metric coarse tooth type, and the thread precision is 6H grade. The anti-theft nut is made of mild steel.

[0020] The most preferred embodiment of the present invention, a kind of processing technology of anti-theft nut of 35KV outdoor pole platform support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com