Continuous tea frying device

A technology for frying tea and frying pan, applied in the direction of tea processing before extraction, can solve the problems of disadvantageous high-automation production, reduce production efficiency, increase labor cost, etc., and achieve the effect of shortening heating time, improving production efficiency, and reducing labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

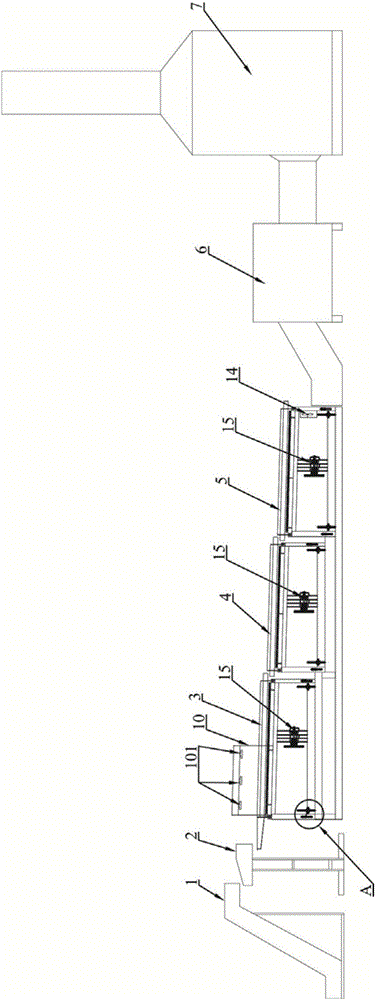

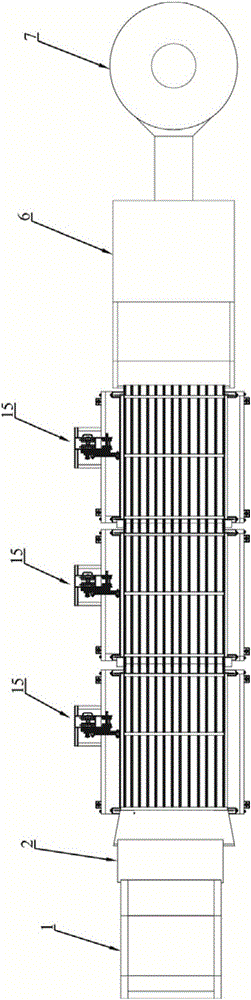

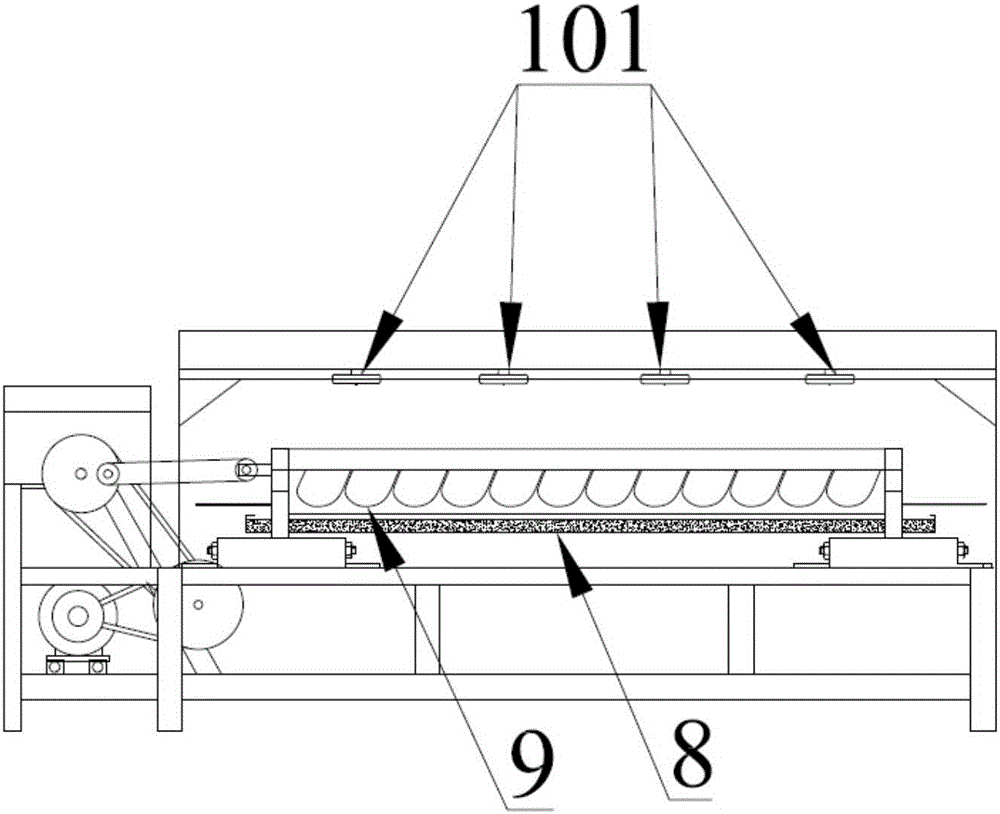

[0037] A continuous tea frying device, comprising an elevator 1, a feeding machine 2, a greening section 3, a stripping section 4, an aroma enhancing section 5, a dryer 6 and a heating machine 7, and the elevator 1 is used to elevate tea leaves to the feeding machine 2. The feeding machine 2 is used to feed the tea leaves lifted by the hoist 1 to the fixing section 3 for tea processing, the fixing section 3 is used for finishing the tea leaves, the stripping section 4 is used for stripping the tea leaves, and the aroma enhancing section 5 is used to enhance the fragrance of the tea leaves, the dryer 6 is used to dry the tea leaves after the fragrance has been enhanced, and the heater 7 is used to provide heat for the dryer 6 .

[0038] The insides of the fixing section 3, the stripping section 4 and the fragrant section 5 are equipped with a heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com