Planting spongy substrate containing biomass activated carbon and preparation method thereof

An activated carbon and sponge-like technology is applied in the field of planting sponge-like matrix containing biomass activated carbon and its preparation. Good sex and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

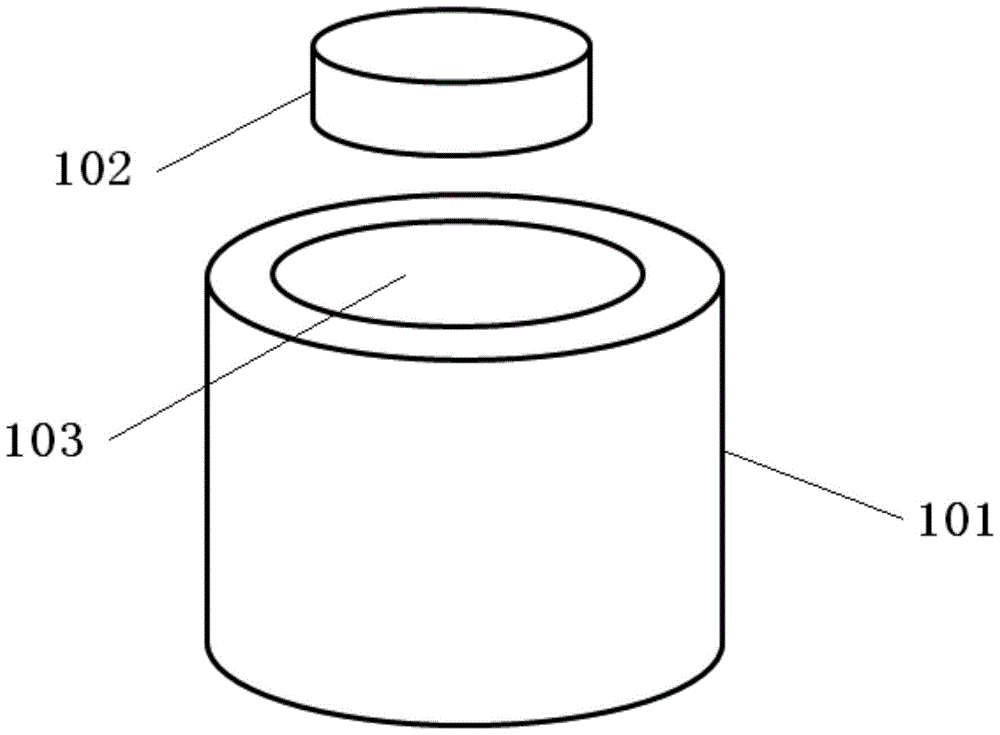

Image

Examples

Embodiment 1

[0029] Take bamboo as the carbon raw material, and pulverize it to particles with a particle diameter less than 2mm; get the above-mentioned carbon raw material particles of 8.5 parts by weight, polyether polyol 330 of 5 parts by weight, hard foam silicone oil of 0.15 parts by weight, 0.06 parts by weight of Water, 0.005 parts by weight of pentamethyldiethylenetriamine, 4 parts by weight of dichlorofluoroethane and 0.15 parts by weight of cycloethylamine, after stirring and mixing at a speed of 500 rpm, add 8.5 parts by weight diphenylmethane diisocyanate, and continue to stir at the above speed for 2 minutes, then place it at room temperature for more than 24 hours, then put it into the muffle furnace; Gradually raise the temperature to 400 degrees Celsius, wherein the heating rate is 10 degrees Celsius / minute, and after reaching 400 degrees Celsius, the carbonization time is 2 hours; the heating state makes the above raw materials react to form a loose, soft and porous sponge...

Embodiment 2

[0035] Take one or more crop straws among corn stalks, wheat straws, and sorghum stalks as carbon raw materials, and crush them into particles with a particle size of less than 2 mm; take 10 parts by weight of the above-mentioned carbon raw material particles, 7 parts by weight of poly Ether polyol 330, 0.2 parts by weight of hard foam silicone oil, 0.1 parts by weight of water, 0.008 parts by weight of pentamethyldiethylenetriamine, 5 parts by weight of dichlorofluoroethane and 0.2 parts by weight of cycloethylamine, After stirring and mixing uniformly at a speed of 900 rpm, add 13 parts by weight of diphenylmethane diisocyanate, and continue to stir at the above speed for 2 minutes, then place it at room temperature for more than 30 hours, and put it into a muffle furnace; Nitrogen or nitrogen containing water vapor is input into the muffle furnace, and the temperature is gradually raised to 250 degrees Celsius in the nitrogen environment of the furnace, and the heating rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com