insulated wire

一种绝缘电线、绝缘层的技术,应用在绝缘电缆、绝缘导体、橡胶绝缘体等方向,能够解决硅橡胶溶胀等问题,达到耐磨损性和耐汽油性优良、抑制成本、提高耐磨损性和耐汽油性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

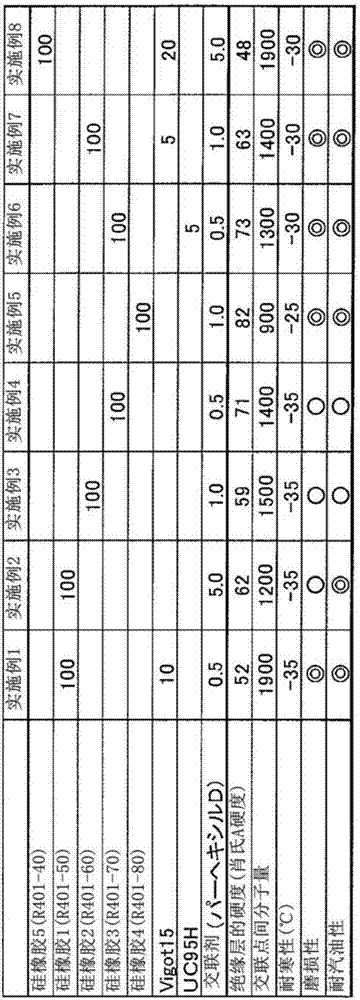

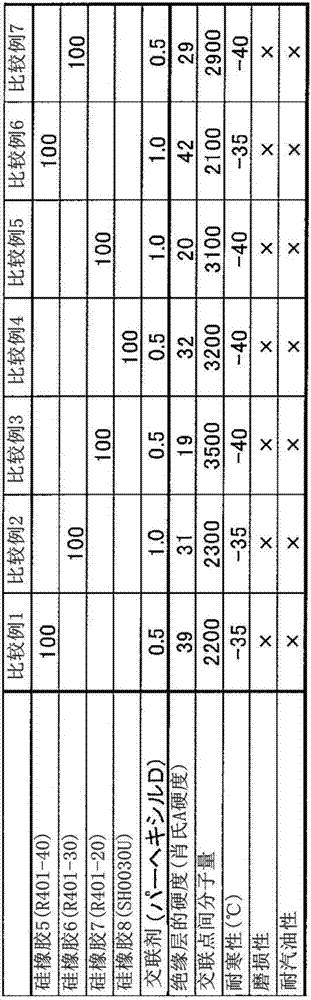

[0058] Each component was mixed so that the compounding composition shown in Table 1 was obtained, and the rubber composition for insulating layers containing a non-crosslinked silicone rubber was prepared. Next, using an extrusion molding machine, the conductor (cross-sectional area of 0.5mm 2 ) was extruded with a rubber composition for covering an insulating layer with a thickness of 0.2 mm (180° C.×5 minutes). Next, the coating layer was heat-treated under the conditions of 200° C.×4 hours, thereby completing the crosslinking of the silicone rubber of the coating layer. Thus, the insulated electric wires of Examples 1-8 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com