All prefabricated cable channel

A cable channel and prefabricated technology, applied in cable installation, ground cable installation, etc., can solve the problems of long construction period and non-mechanized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

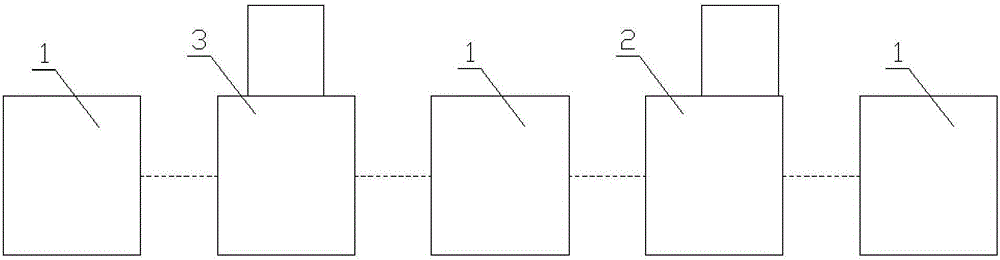

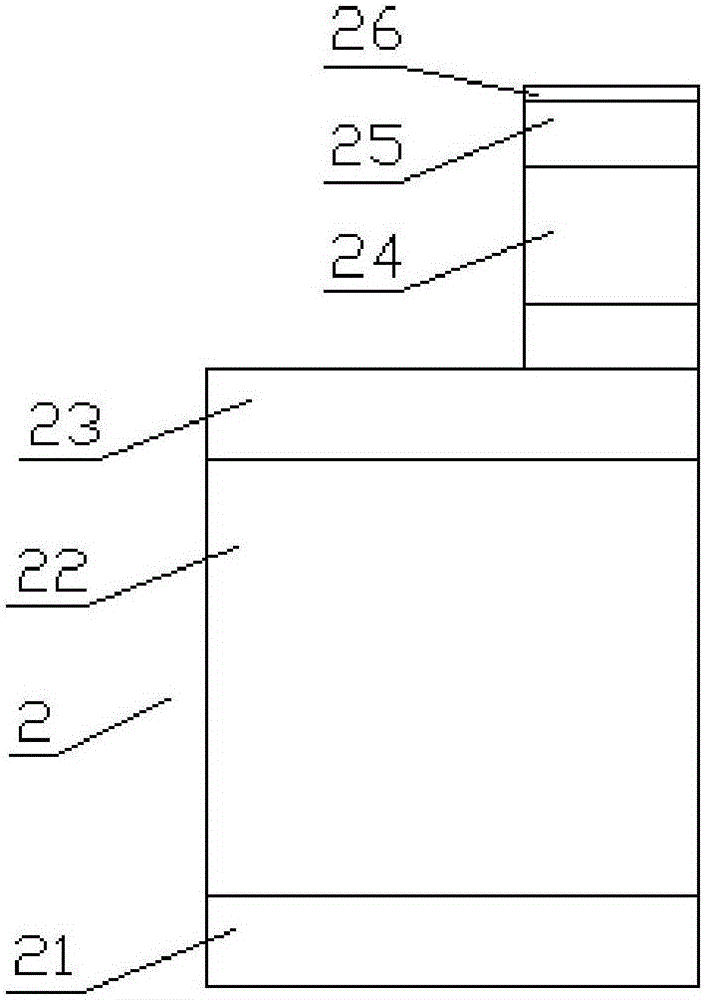

[0021] Such as figure 1 As shown, the fully prefabricated cable channel includes multi-section prefabricated cable trenches 1 spliced together, and prefabricated joint wells 2 and prefabricated working wells 3 are arranged at intervals between the multi-section prefabricated cable trenches 1 .

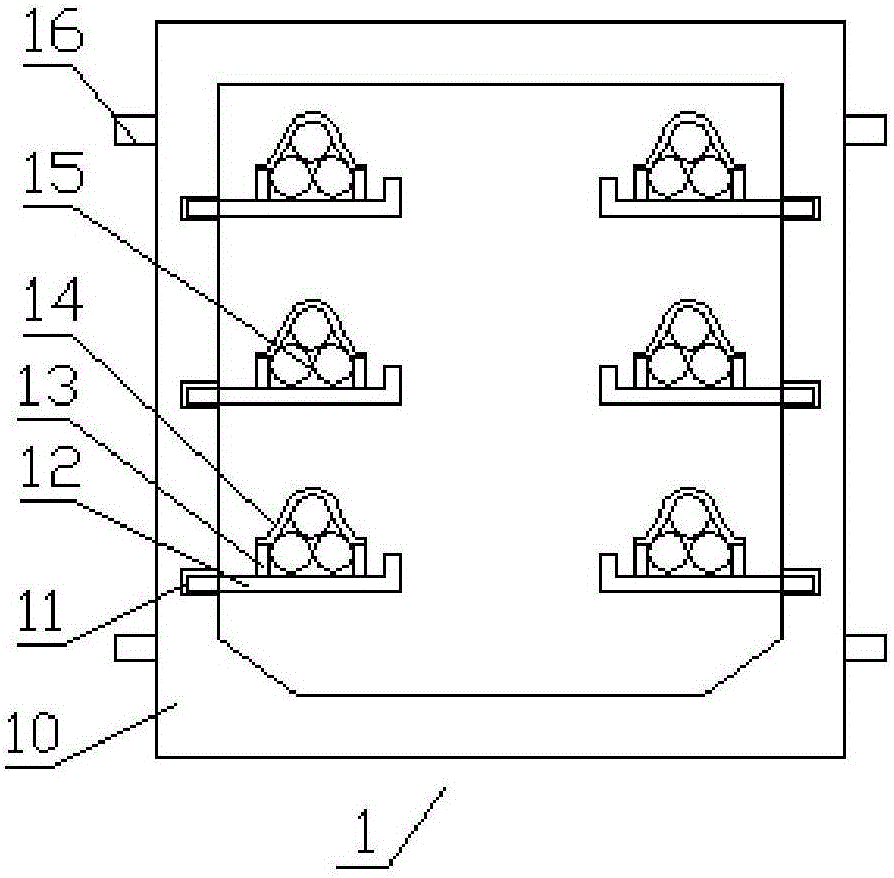

[0022] Such as figure 2 As shown, the prefabricated cable trench 1 includes a rectangular frame body 10, and multi-layer separation grooves 11 are arranged on the inner walls of the left and right sides of the rectangular frame body 10, and a cable pipe installation plate 12 is fixed in the separation groove. A cable row pipe 15 is fixed on the row pipe installation plate 12 .

[0023] Specifically, the cable pipe installation plate 12 is provided with at least two rows of fixing columns 13 along the width direction, the cable row pipes 15 are arranged between the two rows of fixing columns 13, and the fixing columns 13 are fixed with hoops 14, The hoop 14 fixes the cable tubes 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com