A construction method of anti-seepage and anti-corrosion sewage pipeline segment lining based on shield method

A technology for sewage pipelines and shield segments, which is applied in the directions of pipes/pipe joints/fittings, pipe components, and mechanical equipment. Anti-corrosion performance, increase the effective utilization area, the effect of economical construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a construction method for the lining of anti-seepage and anti-corrosion sewage pipeline segments based on the shield method, which includes the following steps:

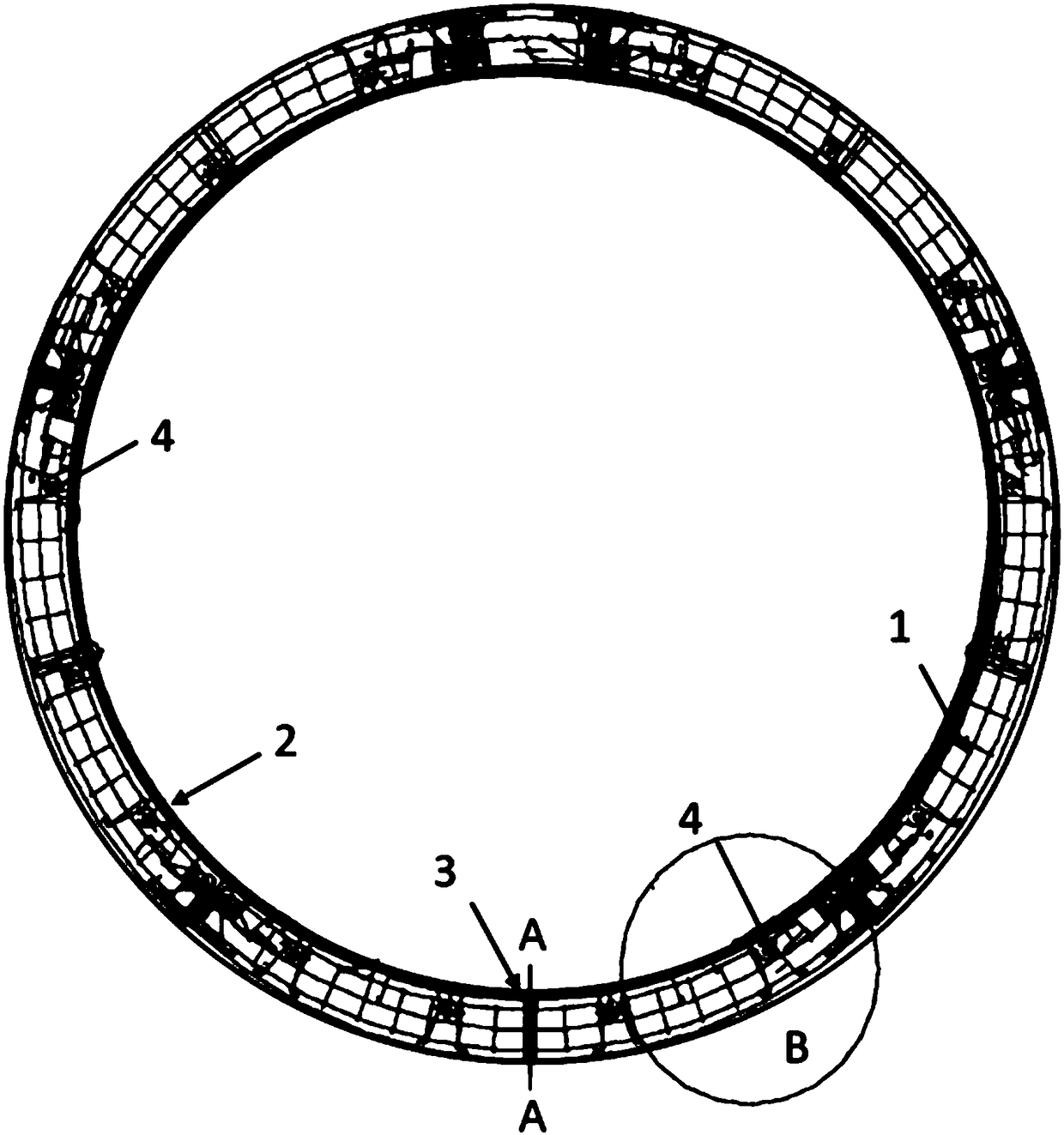

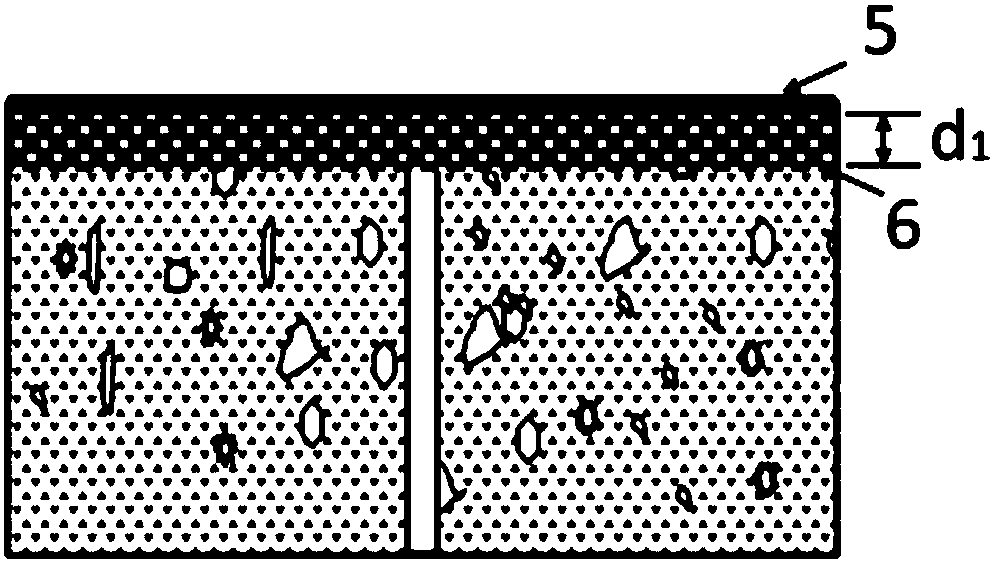

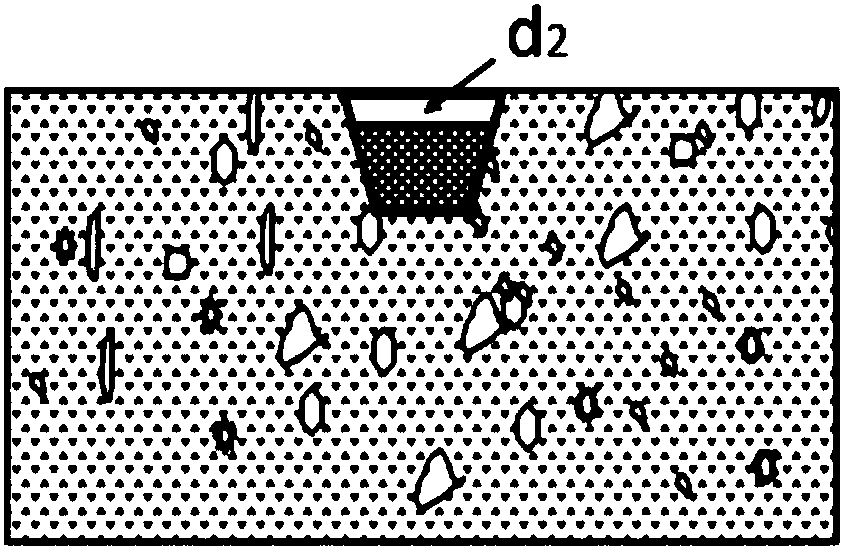

[0024] (a) Use the shield method to excavate a tunnel or hole in the soil, place the shield segment 1 in the tunnel or hole and assemble it into a cylindrical sewage pipe to prevent the soil from collapsing; through secondary grouting Technology Inject polyurethane into the soil to improve its waterproofing, build a self-waterproofing foundation based on the reinforced concrete structure of the shield segment 1, combined with a waterproof defense line improved by soil waterproofing, so that water in the soil can be prevented from penetrating into the shield pipe 1, so as to avoid the situation that the protective coating 2 prepared later is peeled off from the inner arc surface under the gravity of water and the service life is reduced; The holes such as the grouting hole 3 and the bol...

Embodiment 2

[0028] This embodiment provides a construction method for the lining of anti-seepage and anti-corrosion sewage pipe segments based on the shield method. In the coating, the mass ratio of epoxy resin, polyamide curing agent and polyaniline is 1:0.9:0.04; the final measured bonding strength of protective coating 2 is 3MPa, impact strength is 520N cm, and impermeability pressure is 11MPa .

Embodiment 3

[0030] This embodiment provides a construction method for the lining of anti-seepage and anti-corrosion sewage pipe segments based on the shield method. In the coating, the mass ratio of epoxy resin, polyamide curing agent and polyaniline is 1:1.1:0.06; the final measured protective coating 2 has an adhesive strength of 3MPa, an impact strength of 520N cm, and an impervious pressure of 11.2 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com