Radially split double-shell multiple-stage centrifugal pump

A centrifugal pump, double-shell technology, applied in radial flow pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problem of inter-stage leakage, difficult maintenance, and complex shape of multi-stage centrifugal pumps. and other problems, to achieve the effect of high reliability, clean appearance and automatic balance of axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

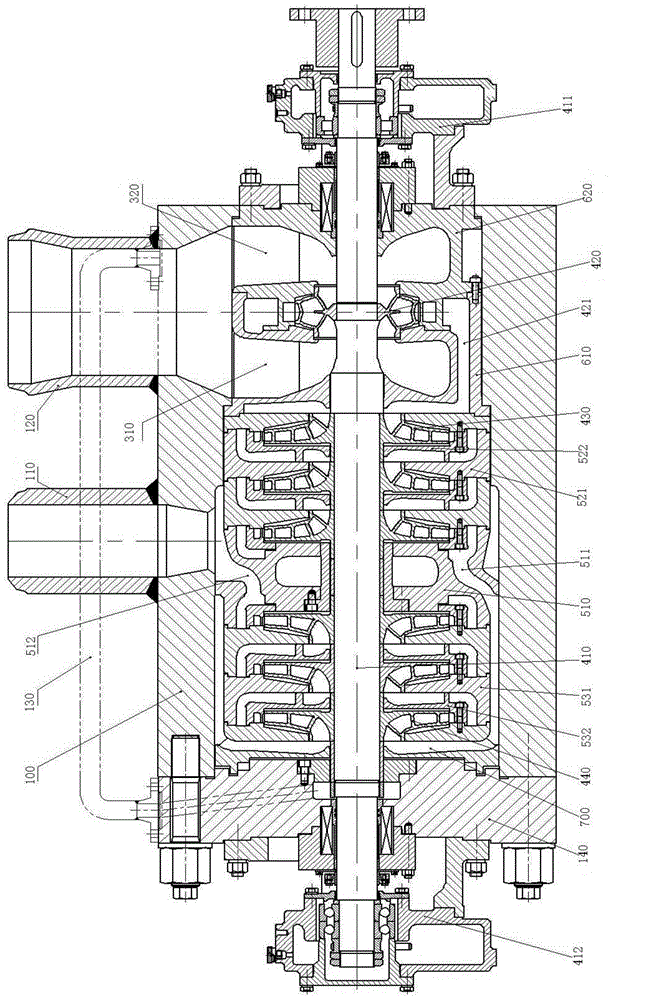

[0020] see figure 1 , a radially split double casing multistage centrifugal pump provided by the present invention mainly includes a cylinder 100, and an outlet pipe 110 and an inlet pipe 120 communicating with the pump cylinder 100 are arranged on the outer surface of the pump cylinder 100 , a pump cover 140 is provided on one side of the cylinder body 100 .

[0021] The inlet pipe 120 can input the external medium into the pump barrel 100 , and the outlet pipe 110 is used to output the working medium in the pump barrel 100 .

[0022] Inside the pump cylinder 100, there is a core package that can be loaded and extracted as a whole. The core package adopts a radial split structure, and it can be loaded or extracted from one end of the pump cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com