In-situ cast-in-place concrete stubble on shaft wall and its supporting formwork device and construction method

A concrete formwork and concrete technology, which is used in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of long construction time, weak connection, and difficult construction, and achieves improved well completion speed, stable and firm structure, and construction speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

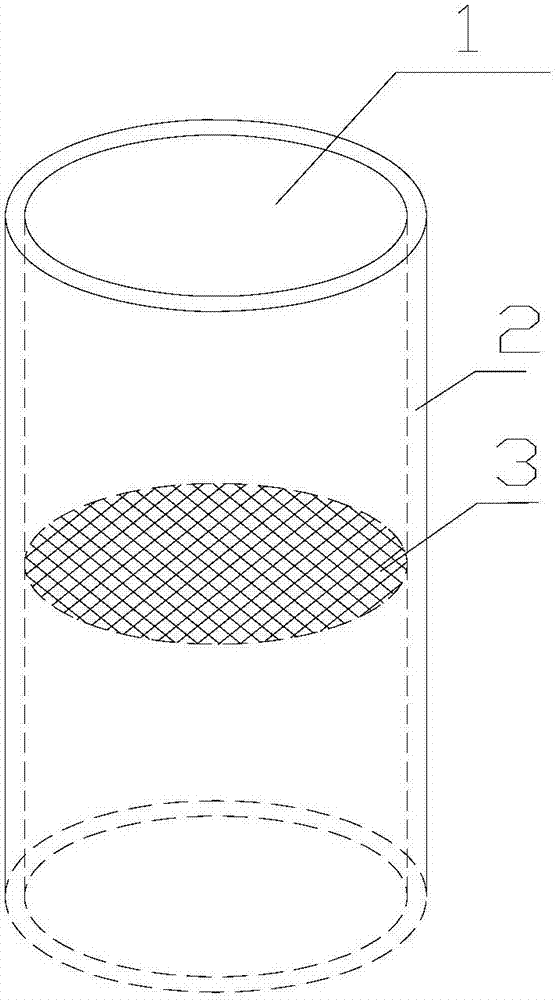

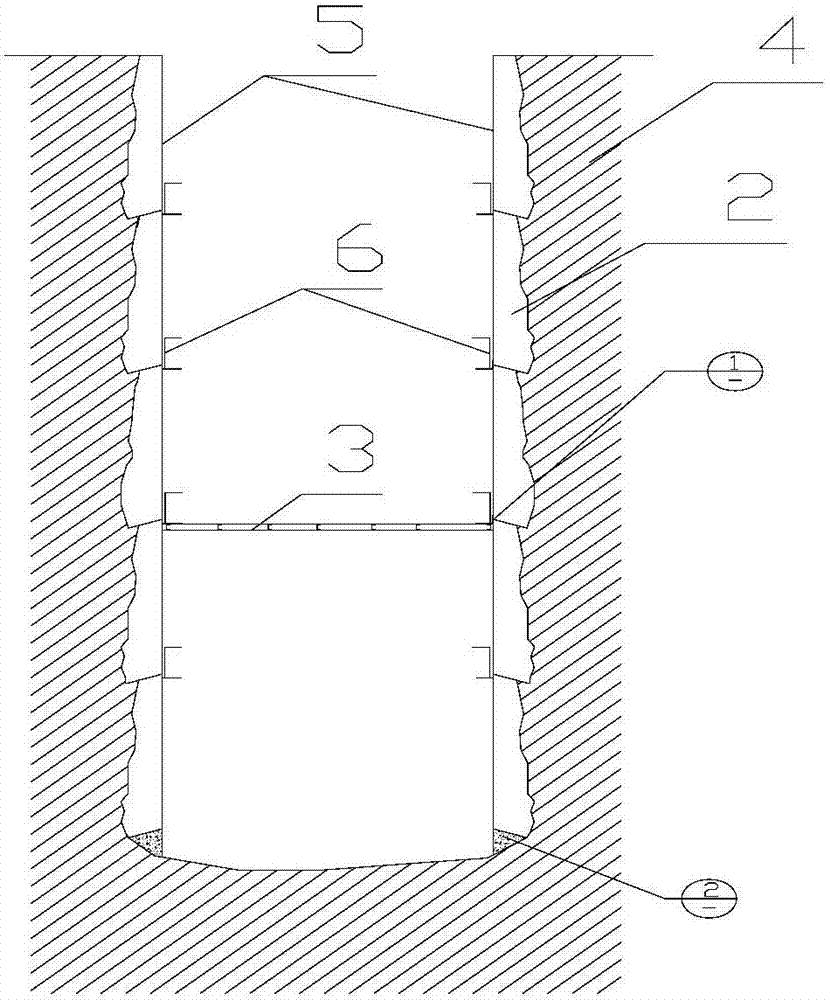

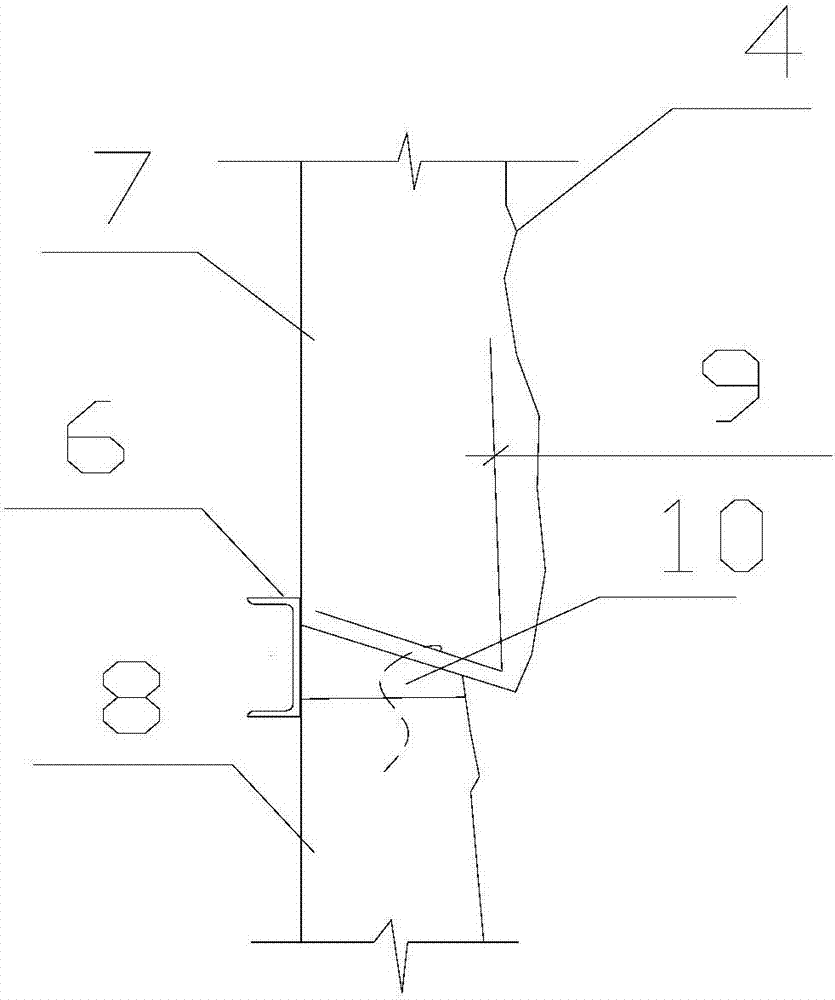

[0033] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 It can be seen that the stubble of the cast-in-place concrete on the shaft wall, including the shaft wall concrete 2, is poured into the shaft 1 in sections, which is characterized in that the joint of the upper and lower shaft wall concrete is provided with a stubble joint, and the lower end of the upper shaft wall concrete 7 is provided with a connecting steel mesh 9 , is connected with the lower shaft wall concrete 8; the two wings of the connecting steel mesh 9 are in an "L" shape, when pouring the upper shaft wall concrete 7, the vertical wings are arranged in the upper shaft wall concrete, and the horizontal wings are placed in the upper shaft wall concrete formwork The lower end with a bevel; before pouring the lower shaft wall concrete 8, straighten the horizontal wing and extend into the upper part of the cavity formed by the preset shaft wall concrete formwork 5 and the surroundi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com