White high-reflectivity EVA compound coating

A high-reflection, composite adhesive technology, used in non-polymer adhesive additives, non-polymer organic compound adhesives, adhesives, etc., can solve the problem of reducing the photoelectric conversion efficiency of solar cell modules, reducing the photoelectric conversion efficiency of modules, reducing Solve the problems such as the amount of light in the cell, to achieve uniform reflectivity, improve the processing performance of EVA, and reduce the induration problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

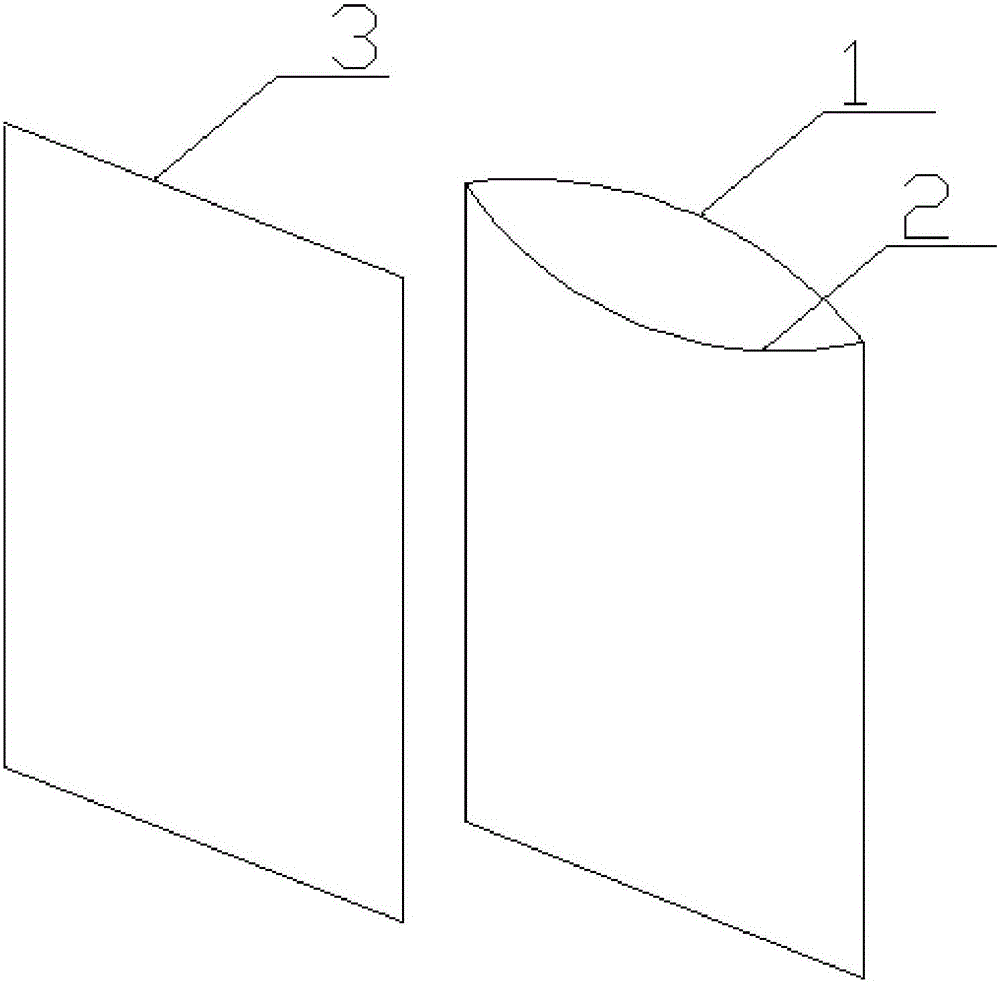

[0046] combined with figure 1 Shown, a kind of white highly reflective EVA composite adhesive film, from the side that receives sunlight, it comprises anti-ultraviolet film layer 1, transparent EVA adhesive film layer 2 and reflective EVA adhesive film layer 3 successively, wherein, described transparent EVA The adhesive film layer 2 and the side of the reflective EVA adhesive film layer 3 are fixed to form a bag-shaped structure with one side open, and the cells for photovoltaic modules are placed in the bag-shaped structure, and the ultraviolet-resistant film layer 1 is arranged on the bag-shaped structure. The front side of the above-mentioned photovoltaic module.

[0047] The adhesive film used in the UV-resistant film layer 1 is an EVA adhesive film for solar cell encapsulation.

[0048] The bag-like structure is also provided with a white non-woven fabric layer, the non-woven fabric layer has a sheet structure, and a number of holes with regular structures are arranged ...

Embodiment 2

[0060] combined with figure 1 Shown, a kind of white highly reflective EVA composite adhesive film, from the side that receives sunlight, it comprises anti-ultraviolet film layer 1, transparent EVA adhesive film layer 2 and reflective EVA adhesive film layer 3 successively, wherein, described transparent EVA The adhesive film layer 2 and the side of the reflective EVA adhesive film layer 3 are fixed to form a bag-shaped structure with one side open, and the cells for photovoltaic modules are placed in the bag-shaped structure, and the ultraviolet-resistant film layer 1 is arranged on the bag-shaped structure. The front side of the above-mentioned photovoltaic module.

[0061] The adhesive film used in the UV-resistant film layer 1 is an EVA adhesive film for solar cell encapsulation.

[0062] The bag-like structure is also provided with a transparent non-woven fabric layer, the non-woven fabric layer has a sheet structure, and several holes with regular structures are arrange...

Embodiment 3

[0073] combined with figure 1 Shown, a kind of white highly reflective EVA composite adhesive film, from the side that receives sunlight, it comprises anti-ultraviolet film layer 1, transparent EVA adhesive film layer 2 and reflective EVA adhesive film layer 3 successively, wherein, described transparent EVA The adhesive film layer 2 and the side of the reflective EVA adhesive film layer 3 are fixed to form a bag-shaped structure with one side open, and the cells for photovoltaic modules are placed in the bag-shaped structure, and the ultraviolet-resistant film layer 1 is arranged on the bag-shaped structure. The front side of the above-mentioned photovoltaic module.

[0074] The adhesive film used in the UV-resistant film layer 1 is an EVA adhesive film for solar cell encapsulation.

[0075] The bag-like structure is also provided with a transparent non-woven fabric layer, the non-woven fabric layer has a sheet structure, and several holes with regular structures are arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com