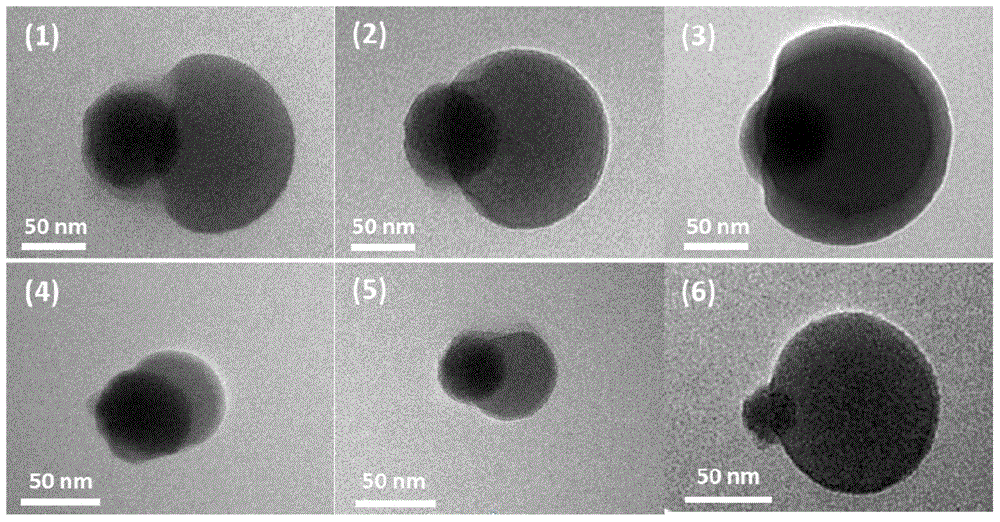

Preparation method of Janus particle containing silicon dioxide with controllable particle size and asymmetrical degree

A silicon dioxide, asymmetric technology, applied in the field of materials, can solve the problems of complex preparation process, lack of Janus particle size and asymmetry, low Janus particle yield, etc., and achieves a simple process, easy implementation, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

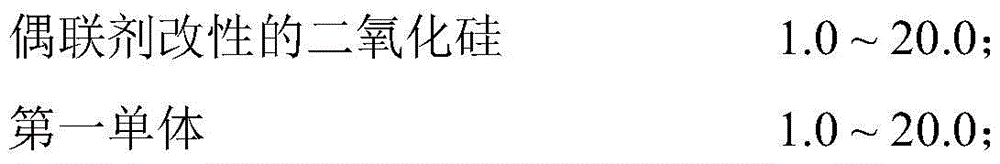

[0033] (a) Preparation of seed emulsion:

[0034]

[0035]

[0036] According to the above ratio, add coupling agent-modified silica, first monomer, hydrophilic monomer, crosslinking agent, emulsifier and deionized water into the reaction device, start stirring, condense and reflux, and pass nitrogen for 20 minutes , heated up to 60°C, added an initiator, polymerized for 4.0 hours, and obtained a seed emulsion;

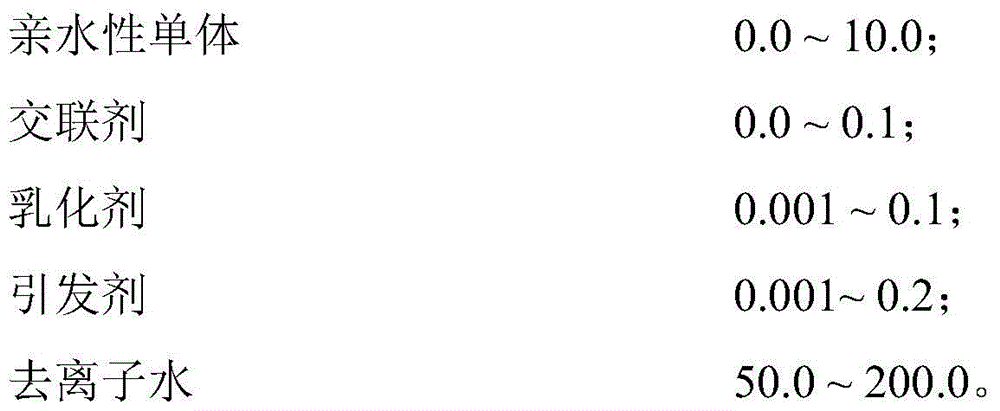

[0037] (b) Preparation of Janus particles:

[0038]

[0039]Add deionized water to the seed emulsion in step (a), ultrasonically disperse for 30 minutes, start stirring, condense and reflux, blow nitrogen for 20 minutes, add the second monomer to swell at room temperature for 20 minutes, raise the temperature to 70°C, add an initiator, and polymerize for 5.0 h, the emulsion was centrifuged and vacuum-dried to obtain Janus particles. Among them, the diameter of the silica modified by the coupling agent is 80nm, and the grafting density of the silica surface ...

Embodiment 2

[0041] (a) Preparation of seed emulsion:

[0042]

[0043]

[0044] According to the above ratio, add coupling agent-modified silica, first monomer, hydrophilic monomer, crosslinking agent, emulsifier and deionized water into the reaction device, start stirring, condense and reflux, and pass nitrogen for 20 minutes , heated up to 60°C, added an initiator, polymerized for 4.0 hours, and obtained a seed emulsion;

[0045] (b) Preparation of Janus particles:

[0046]

[0047] Add deionized water to the seed emulsion in step (a), ultrasonically disperse for 30 minutes, start stirring, condense and reflux, blow nitrogen for 20 minutes, add the second monomer to swell at room temperature for 40 minutes, raise the temperature to 70°C, add an initiator, and polymerize for 5.0 h, the emulsion was centrifuged and vacuum-dried to obtain Janus particles. Among them, the diameter of the silica modified by the coupling agent is 80nm, and the grafting density of the silica surface...

Embodiment 3

[0049] (a) Preparation of seed emulsion:

[0050]

[0051] According to the above ratio, add coupling agent-modified silica, first monomer, hydrophilic monomer, crosslinking agent, emulsifier and deionized water into the reaction device, start stirring, condense and reflux, and pass nitrogen for 20 minutes , heated up to 60°C, added an initiator, polymerized for 4.0 hours, and obtained a seed emulsion;

[0052] (b) Preparation of Janus particles:

[0053]

[0054] Add deionized water to the seed emulsion in step (a), ultrasonically disperse for 30 minutes, start stirring, condense and reflux, blow nitrogen for 20 minutes, add the second monomer to swell at room temperature for 40 minutes, raise the temperature to 70°C, add an initiator, and polymerize for 5.0 h, the emulsion was centrifuged and vacuum-dried to obtain Janus particles. Among them, the diameter of the silica modified by the coupling agent is 80nm, and the grafting density of the silica surface coupling ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com