Method for preparing polysulfide silane coupling agent by passage reaction device

A technology of channel reaction device and silane coupling agent, which is applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., and can solve problems such as unsafety, long reaction cycle, and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

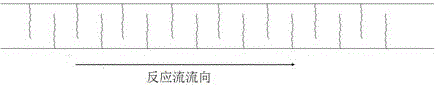

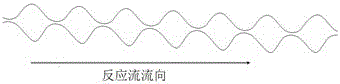

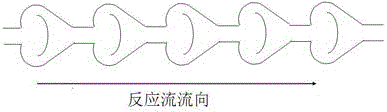

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Preparation of Si17.

[0051] The mass ratio of raw material caustic soda (solid sodium hydroxide), sulfur powder, solvent water, phase transfer catalyst tetrabutylammonium bromide, and 3-chloropropyltriethoxysilane is 120:150:330:4:480 .

[0052] Dissolve tetrabutylammonium bromide in water to form a catalyst solution, the mass ratio of the two is 1:6, and the temperature is controlled at 10°C-50°C; the caustic soda, sulfur powder and the remaining water are mixed at 50°C-80°C Prepare sodium polysulfide aqueous solution under reaction; Mix sodium polysulfide aqueous solution and catalyst solution and keep the temperature at 50°C-70°C, enter the channel reaction device from a feed port of the channel reaction device, and simultaneously 3-chloropropyltri The ethoxysilane is fed into the channel reaction device to mix and react with the sodium polysulfide aqueous solution, and the reaction temperature is controlled at 84-86°C. Sampling is taken from the coll...

Embodiment 2

[0053] Example 2 Prepare a polysulfide silane coupling agent with an average value of n of 2.20~2.50, corresponding to the product Si75 in GB / T30309-2013.

[0054] The mass ratio of raw material sodium sulfide pentahydrate, sulfur powder, solvent water, phase transfer catalyst tetrabutylammonium bromide, pH regulator sodium bicarbonate, 3-chloropropyltriethoxysilane is 175:45:280: 4:60:478.

[0055] Dissolve tetrabutylammonium bromide in water to form a catalyst solution, the mass ratio of the two is 1:6, and the temperature is controlled at 10°C-50°C; sodium sulfide pentahydrate, sulfur powder, sodium bicarbonate and the remaining water are mixed in Prepare sodium polysulfide aqueous solution by reacting at 50°C-80°C; mix sodium polysulfide aqueous solution and catalyst solution and keep the temperature at 50°C-70°C, enter the channel reaction device from a feed port of the channel reaction device, and simultaneously put 3-Chloropropyltriethoxysilane is passed into the cha...

Embodiment 3

[0056] Example 3 Prepare a polysulfide silane coupling agent with an average value of n of 2.05~2.25, corresponding to the product Si85 in GB / T30309-2013.

[0057] The mass ratio of raw materials sodium sulfide pentahydrate, sulfur powder, solvent water, phase transfer catalyst tetrabutylammonium bromide, pH regulator sodium carbonate, and 3-chloropropyltriethoxysilane is 175:37:280:4 :50:478.

[0058] Dissolve tetrabutylammonium bromide in water to form a catalyst solution, the mass ratio of the two is 1:6, and the temperature is controlled at 10°C-50°C; sodium sulfide pentahydrate, sulfur powder, sodium carbonate and the remaining water are mixed at 50 Under the condition of ℃-80 ℃, react to prepare sodium polysulfide aqueous solution; mix sodium polysulfide aqueous solution and catalyst solution and keep the temperature at 50 ℃-70 ℃, enter the channel reaction device from a feed port of the channel reaction device, and simultaneously put 3 -Chloropropyltriethoxysilane is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com