A method of using zero-valent nano-iron to strengthen sludge anaerobic digestion to produce methane

A zero-valent nano-iron and anaerobic digestion technology, applied in the field of solid waste recycling, can solve the problems of incomplete degradation of organic matter, low methane production efficiency, and high energy consumption, achieve low cost, improve energy recovery rate, and reduce consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

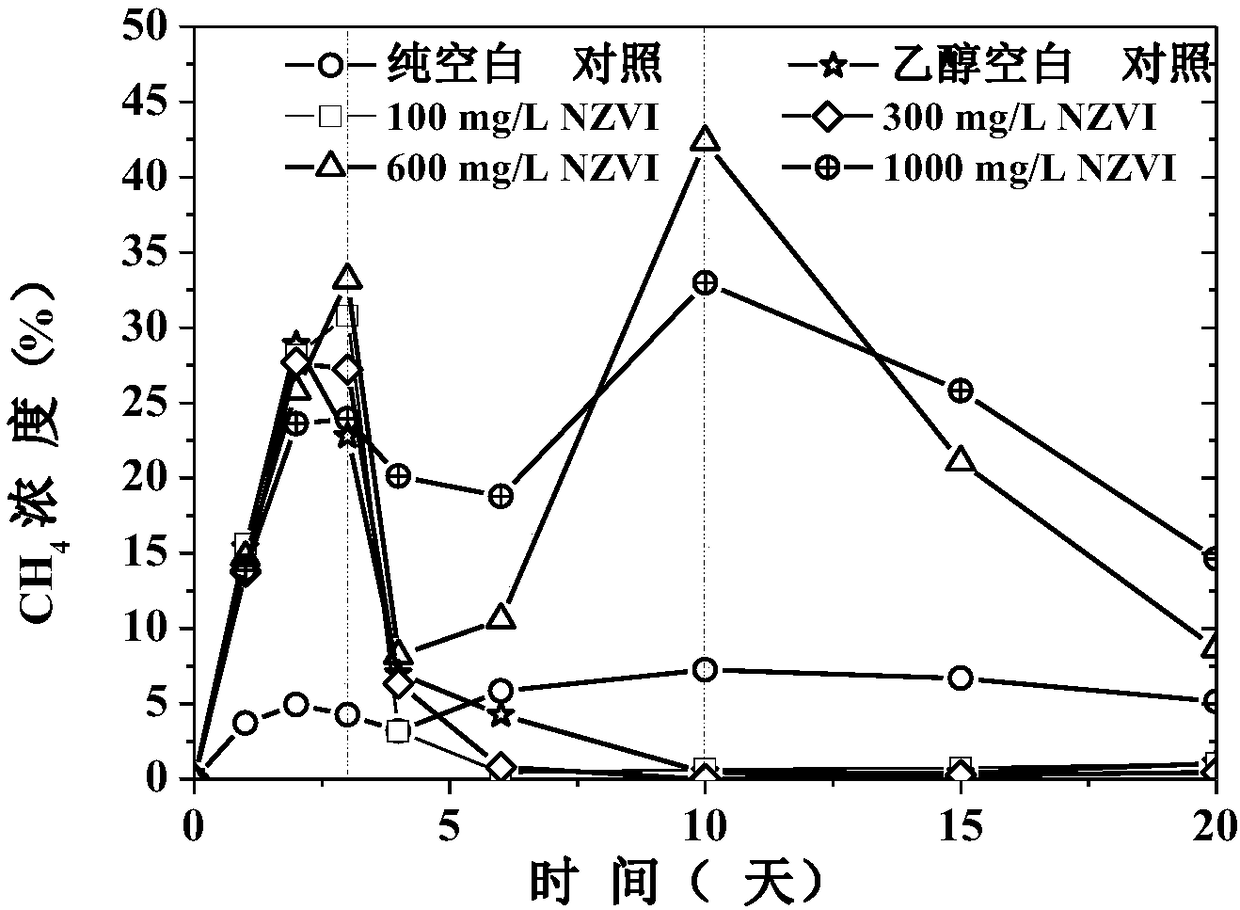

[0022] Embodiment 1-6, wherein the zero-valent nano-iron dosage of embodiment 1 and 2 is 0, and the zero-valent nano-iron dosage of embodiment 3,4,5,6 is successively 100 (mg / L), 300 (mg / L), 600 (mg / L) and 1000 (mg / L), the dosage of ethanol is 1 (mL) except that embodiment 1 is 0. Other processes and conditions are the same.

[0023] A. The sludge is anaerobic digested sludge from an anaerobic digester of a sewage treatment plant in Shanghai. According to the standard method, the total suspended solids concentration (SS=14.683g / L), the volatile suspended solids concentration (VSS=6.841g / L), and the total chemical oxygen demand (COD=2263mg / L) of the anaerobic digested sludge were measured. . Adjust pH≈7.

[0024] B, through N 2 When the oxidation-reduction potential (ORP) is less than -300mV (usually 30min). Then, at N 2 Under the protection, the sludge of step A is packed into embodiment 1,2,3,4,5,6 used specification respectively is 500mL, and working volume is 300mL a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com