Advanced treatment method for sewage sludge

A technology for advanced treatment and sewage sludge, which is applied in the directions of sludge treatment, dehydration/drying/thickened sludge treatment, water/sludge/sewage treatment, etc. It can solve the problem of low freezing efficiency, increased sludge treatment capacity, and inability to recycle Incineration waste heat and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

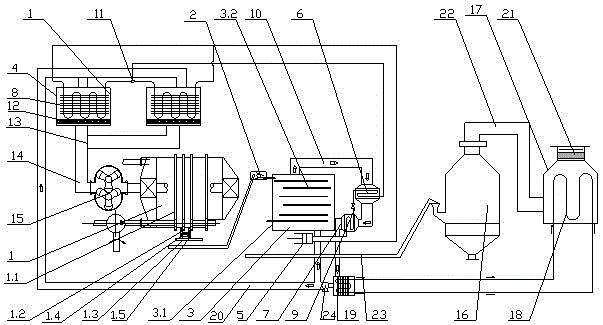

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

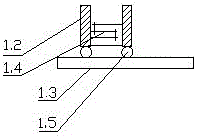

[0024] As shown in the figure, a sewage sludge advanced treatment method of the present invention is realized based on a sludge treatment device, which includes a filter press device 1, a crushing device 2, a drying device 3, an incineration device 16 and a waste heat boiler 17, The filter press device 1 performs pressure filtration treatment on the sludge, and then the crushing device 2 carries out the crushing treatment. After the sludge is crushed, it enters the drying device 3 for drying treatment, and the dried sludge particles are sent to the incineration device 16 for incineration (from the drying device. The feeding port enters the incineration device through the conveying mechanism 23), and the high-temperature flue gas generated by incineration enters the waste heat boiler 17;

[0025]The sewage sludge treatment device also includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com