A hinged assembly for connecting the lower bracket of the eps steering column and the instrument beam

A steering column and articulation technology, which is applied to the steering column, the upper structure sub-assembly, the steering control installed on the vehicle, etc. Problems such as large output torque, to achieve the effect of preventing slipping, preventing follow-up, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

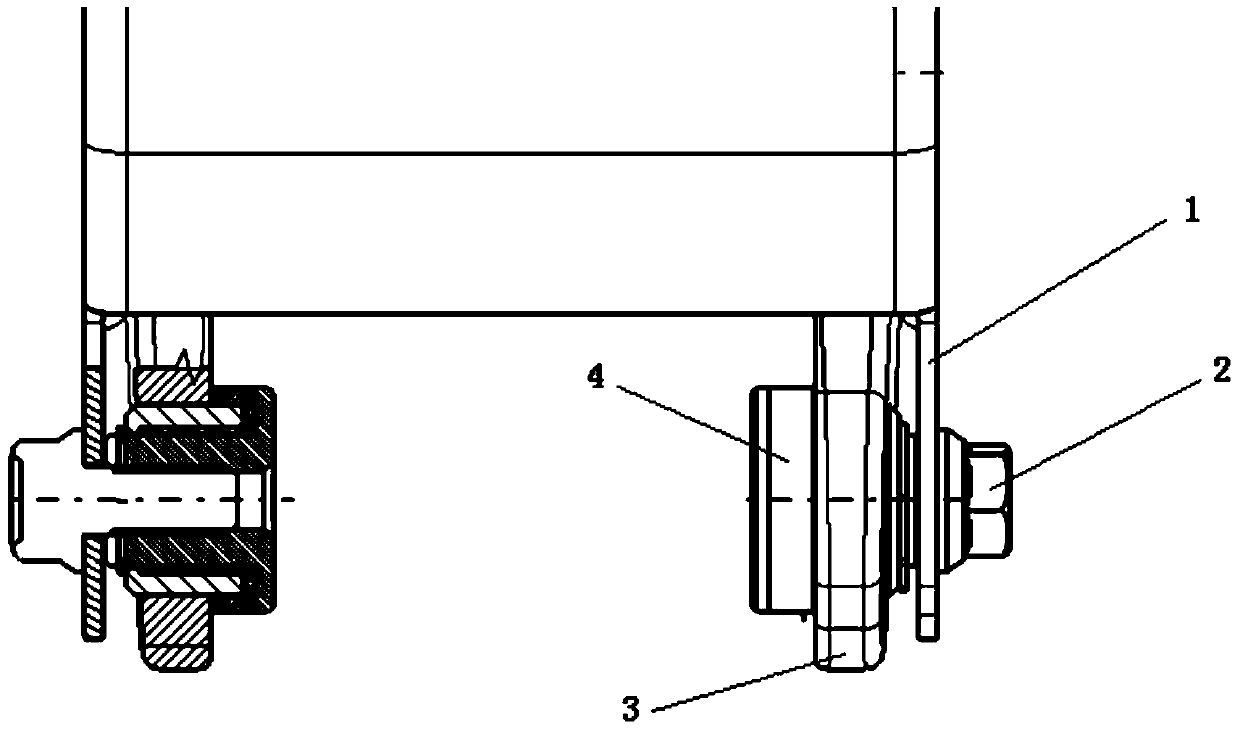

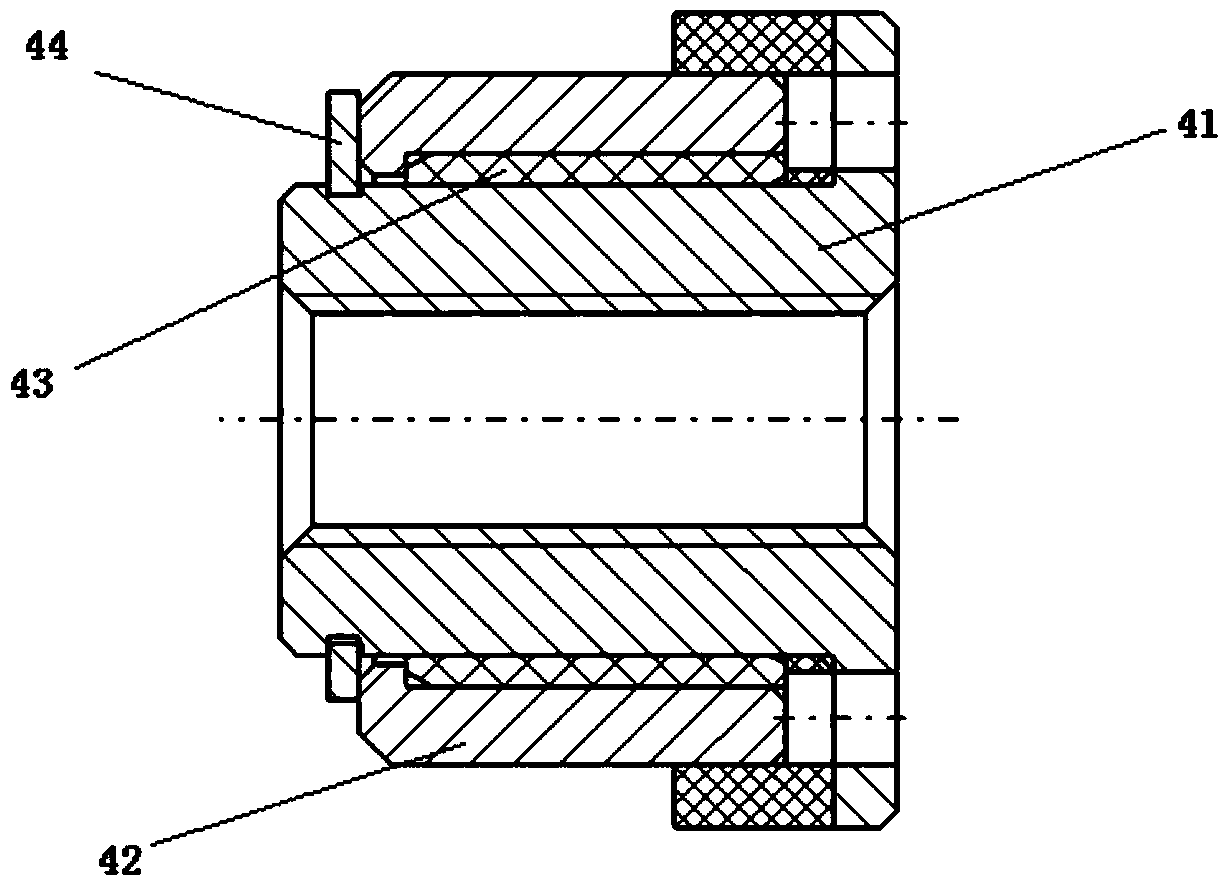

[0027] like Figure 1~2 As shown, a hinge assembly for connecting the EPS steering column lower bracket and the instrument beam, the hinge assembly 4 is interference fitted in the mounting hole of the steering column lower bracket 3, wherein the hinge assembly 4 includes a hinge Shaft core 41, sliding bearing 43 and hinged bushing 42, the middle part of hinged shaft core 41 is provided with threaded through hole along the axial direction, and one end of described hinged shaft core 41 is provided with flange surface, and this flange surface and steering The inner surface of the column lower bracket 3 is fitted together, and the other end is fitted with the instrument beam 1 through the fastening bolt 2. The hinge bush 42 is set on the hinge shaft core 41, and the sliding bearing 43 is arranged on the hinge shaft core 41 and the hinge shaft core 41. Between the bushings 42, when the steering wheel turns left and right, the steering column lower bracket 3 will receive the alterna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com