Box body forming device

A molding device and box body technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of low box quality, high labor intensity, and unequal bottom pressure, achieve uniform pressure distribution, and save production and processing. Cost, Ease of Operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

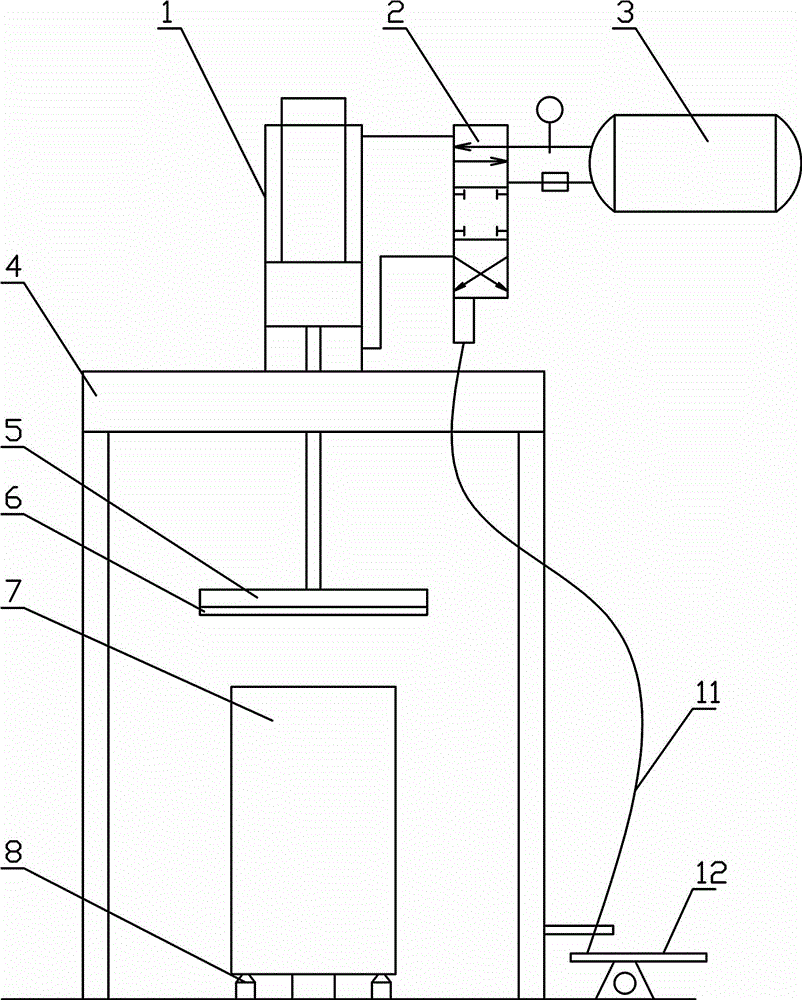

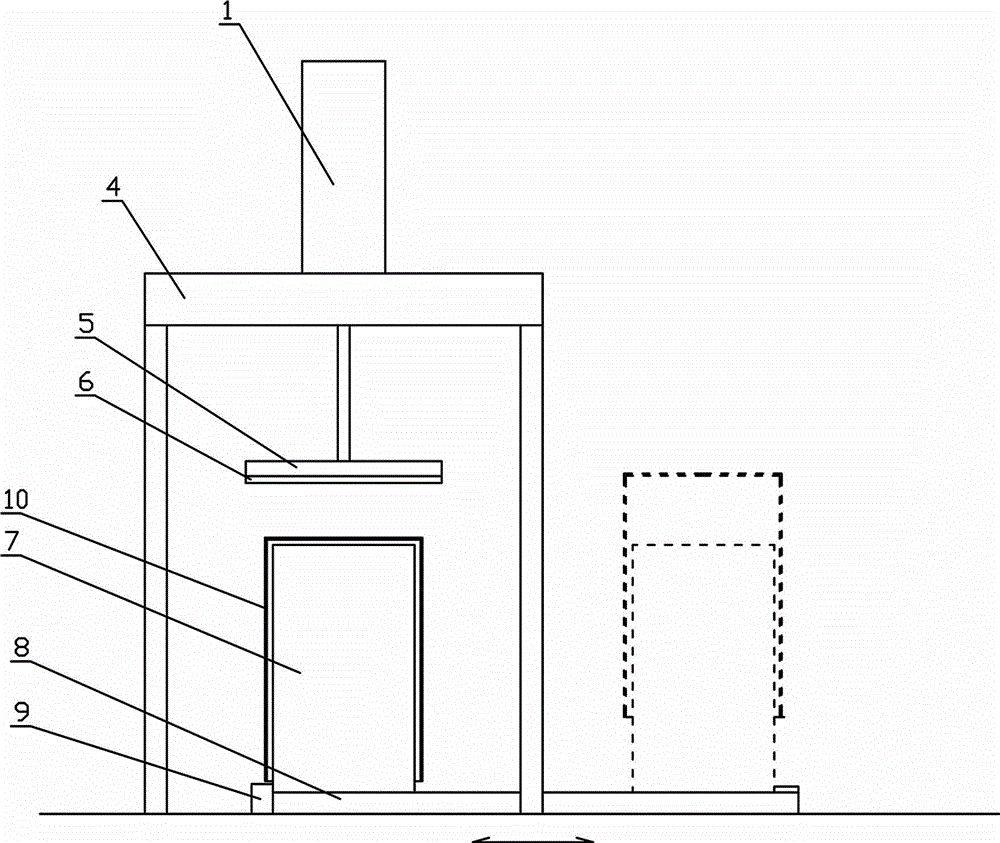

[0012] Such as figure 1 , 2 Among them, a box body forming device, a door frame 4, a cylinder 1 is provided on the door frame 4, a pressure head 5 is provided at the end of the piston rod of the cylinder 1, and a bearing block 7 is provided at the position below the pressure head 5, and the cylinder 1 passes through The pipeline is connected to the reversing valve 2, and the pipeline distance between the reversing valve 2 and the cylinder 1 is less than 50mm; further preferably, the reversing valve 2 is directly installed on the outer wall of the cylinder 1, so the pipeline can be shortened to less than 20mm Inside, the response time of the cylinder is greatly accelerated. The reversing valve 2 is connected with the pedal 12 through the casing wire rope 11, and the reversing valve 2 is driven to reversing through the pedal 12. The mechanical reversing valve is used to replace the electromagnetic reversing valve, so that the pedal 12 is stepped on, and the reversing valve 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com