Device for cutting material sheets

A technology of equipment and cutting strips, which is applied in the manufacture of rigid/semi-rigid containers, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as cost, and achieve the effects of saving tool replacement, improving production efficiency, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

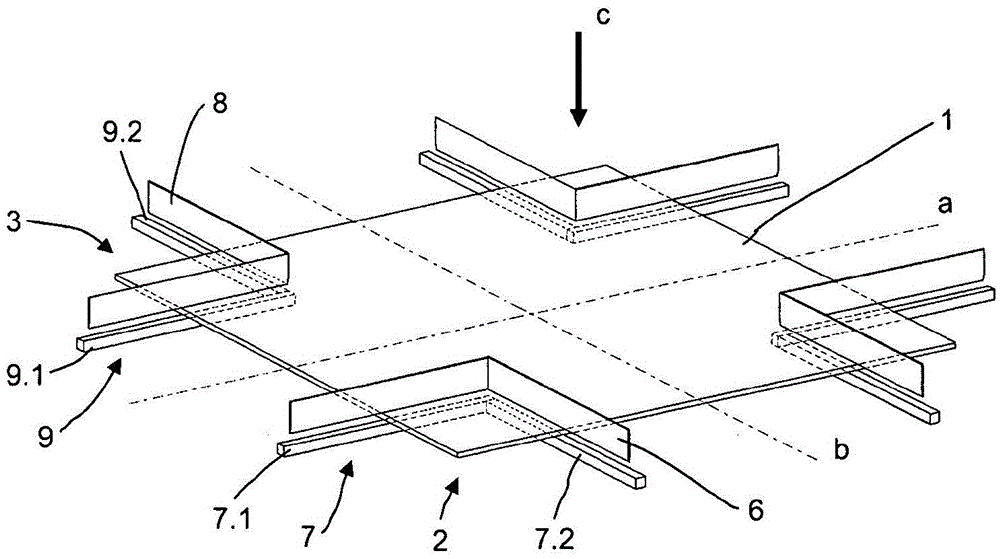

[0020] The cutting chamber of the device comprises four identical cutting units 4 each comprising a knife 6, 8 with a right-angle profile and a cutting bar 7, 9 arranged at right angles to each other and having a square transverse profile. Subsections 7.1 and 7.2 or 9.1 and 9.2 of the section. figure 1 The layout of the tool is shown, in which the corners of the tool point in each case into the entire material sheet 1 and in each case a partial leg of two opposing knives 6 , 8 is oriented coaxially. The sub-legs of the knives 6, 8 and correspondingly associated cutting elements 7, 9 protrude over the entire sheet of material 1, so that each cutting unit 4 cuts out a rectangular area 2, 3 in each case, resulting in a cross-shaped cut pieces. Such a tool configuration is suitable, for example, for cutting off corner regions of cardboard or box lids cut into a cross-recess shape, which can be further processed into dimensionally stable boxes.

[0021] figure 2 One of four cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com