Intelligent tubular oppositely-opened type stirring machine

A split-type, mixer technology, applied in the direction of mixer accessories, mixers, dissolving, etc., can solve the problems of low automation, low output, difficult to achieve dry humidity, etc., to achieve uniform mixing, easy cleaning, quality assurance and molding rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

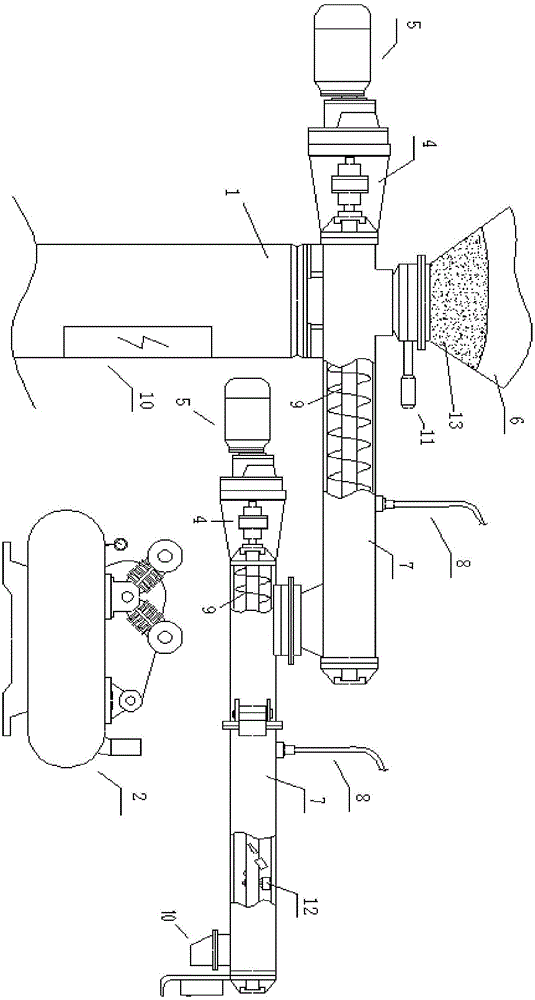

[0012] Referring to the accompanying drawings, the intelligent tubular split mixer includes a base 1, a multi-stage stirring tube device and an air compressor 2. The multi-stage stirring tube device is composed of a first-stage stirring tube device and a second-stage stirring tube device. The stirring tube device includes a primary stirring tube 3, the rear end of the primary stirring tube 3 is connected to the deceleration motor 5 through an elastic coupling 4, the primary stirring tube 3 is fixed on the base 1, and the primary stirring tube 3 is connected to the high-level silo 6 , the secondary stirring tube device includes a secondary stirring tube 7, the secondary stirring tube 7 is connected to the deceleration motor 5 through the elastic coupling 2, and the discharge port of the primary stirring tube and the feeding port of the secondary stirring tube Connected, the primary stirring tube and the secondary stirring tube are provided with a binder feeding system 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com