Pipe diaphragm pump remote monitoring system and method based on wireless network and GPRS

A remote monitoring system and wireless network technology, applied in the field of pipeline diaphragm pump remote monitoring system, can solve the problems that it is difficult to deal with the pipeline diaphragm pump in the first time, and the staff is difficult to monitor, etc., so as to achieve convenient viewing and analysis, and fast data transmission rate , good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

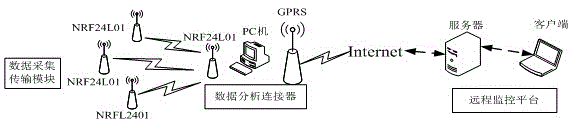

[0036] Embodiment 1: as Figure 1-4 As shown, the pipeline diaphragm pump remote monitoring system based on wireless network and GPRS, including data acquisition and transmission module, data analysis connector, remote monitoring platform;

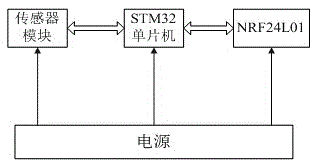

[0037]The data acquisition and transmission module includes a sensor module, STM32 single-chip microcomputer Ⅰ, and NRF24L01 radio frequency module Ⅰ; the sensor module, STM32 single-chip microcomputer Ⅰ, and NRF24L01 wireless radio frequency module Ⅰ are connected in sequence; the sensor module of the whole system is installed in the axial direction of the pipeline diaphragm pump, radially and vertically;

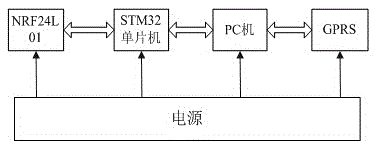

[0038] The data analysis connector includes NRF24L01 radio frequency module II, STM32 single-chip microcomputer II, PC, and GPRS wireless transmission module; NRF24L01 wireless radio frequency module II, STM32 single-chip microcomputer II, PC, and GPRS wireless transmission module are connected in sequence, and the GPRS wireless transm...

Embodiment 2

[0049] Embodiment 2: as Figure 1-4 As shown, the pipeline diaphragm pump remote monitoring system based on wireless network and GPRS, including data acquisition and transmission module, data analysis connector, remote monitoring platform;

[0050] The data acquisition and transmission module includes a sensor module, STM32 single-chip microcomputer Ⅰ, and NRF24L01 radio frequency module Ⅰ; the sensor module, STM32 single-chip microcomputer Ⅰ, and NRF24L01 wireless radio frequency module Ⅰ are connected in sequence; the sensor module of the whole system is installed in the axial direction of the pipeline diaphragm pump, radially and vertically;

[0051] The data analysis connector includes NRF24L01 radio frequency module II, STM32 single-chip microcomputer II, PC, and GPRS wireless transmission module; NRF24L01 wireless radio frequency module II, STM32 single-chip microcomputer II, PC, and GPRS wireless transmission module are connected in sequence, and the GPRS wireless trans...

Embodiment 3

[0063] Embodiment 3: as Figure 1-4 As shown, the pipeline diaphragm pump remote monitoring system based on wireless network and GPRS, including data acquisition and transmission module, data analysis connector, remote monitoring platform;

[0064] The data acquisition and transmission module includes a sensor module, STM32 single-chip microcomputer Ⅰ, and NRF24L01 radio frequency module Ⅰ; the sensor module, STM32 single-chip microcomputer Ⅰ, and NRF24L01 wireless radio frequency module Ⅰ are connected in sequence; the sensor module of the whole system is installed in the axial direction of the pipeline diaphragm pump, radially and vertically;

[0065] The data analysis connector includes NRF24L01 radio frequency module II, STM32 single-chip microcomputer II, PC, and GPRS wireless transmission module; NRF24L01 wireless radio frequency module II, STM32 single-chip microcomputer II, PC, and GPRS wireless transmission module are connected in sequence, and the GPRS wireless trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com