Dual-display winding machine of shaping rotor

A winding machine and rotor technology, which is applied in the field of double-display winding machines for shaping rotors, can solve the problems of operators’ palm damage, difficulty in ensuring winding quality, and large volume of shaping rotors, so as to achieve convenient installation, improve work efficiency and The effect of applicability, wide application and promotion prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

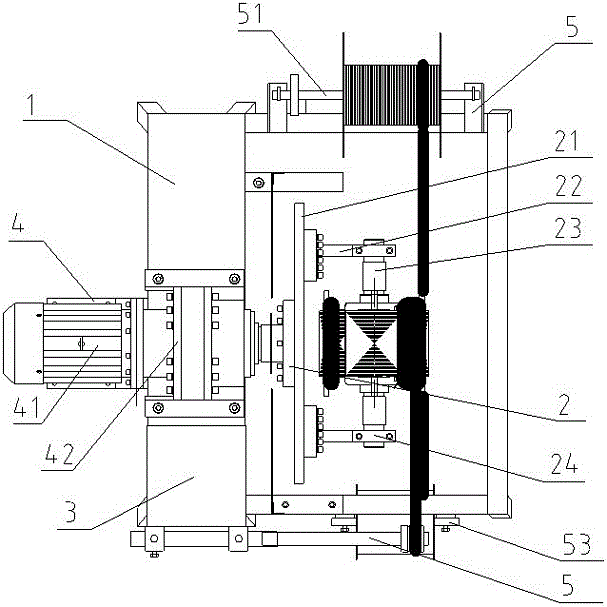

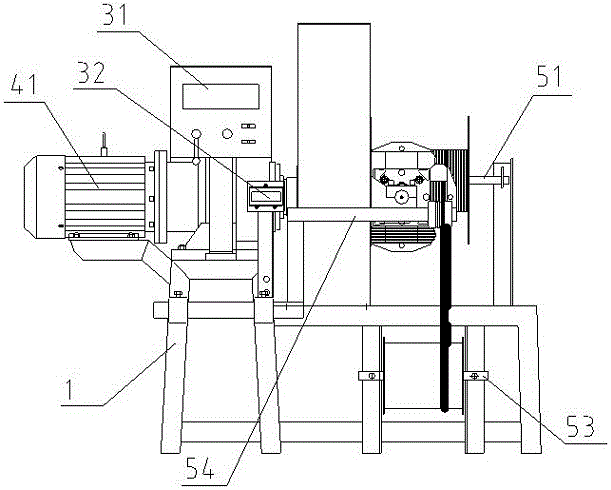

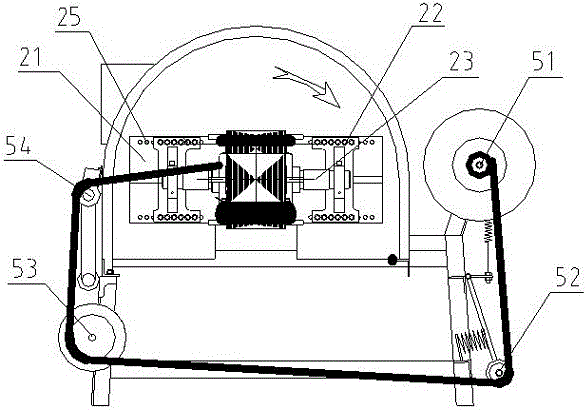

[0022] As shown in the figure, a shaping rotor double-display winding machine includes a working frame 1, a rotor clamp 2, a driving device 4 and a coil clamp 5; the driving device 4 is installed on the working frame 1; the rotor clamping 2 includes a rotating plate 21, a bracket 22, and a rotor shaft 23; the rotating plate 21 is installed on the driving shaft of the driving device 4, and rotates following the rotation of the driving shaft; the supporting frame 22 is provided with two, respectively On the rotating plate 21, it is located on both sides of the connecting point between the rotating plate 21 and the drive shaft; the bracket 22 is provided with a mounting plate 24; the mounting plates 24 on the two brackets 22 correspond to each other, and the rotor shaft 23 can Assembled on the rotor fixture 2 through the two mounting plates 24;

[0023] The coil fixture 5 is arranged corresponding to the rotor fixture 2 , and the coil assembled on the coil fixture 5 is in the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com