Motor convenient for fluid flowing

One kind of fluid flow and another group of technologies are applied in the shape/style/structure of winding conductors, prevention/reduction of eddy current loss in winding heads, etc., which can solve problems affecting heat dissipation of motors, and achieve faster convection heat dissipation, faster flow speed, The effect of promoting heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

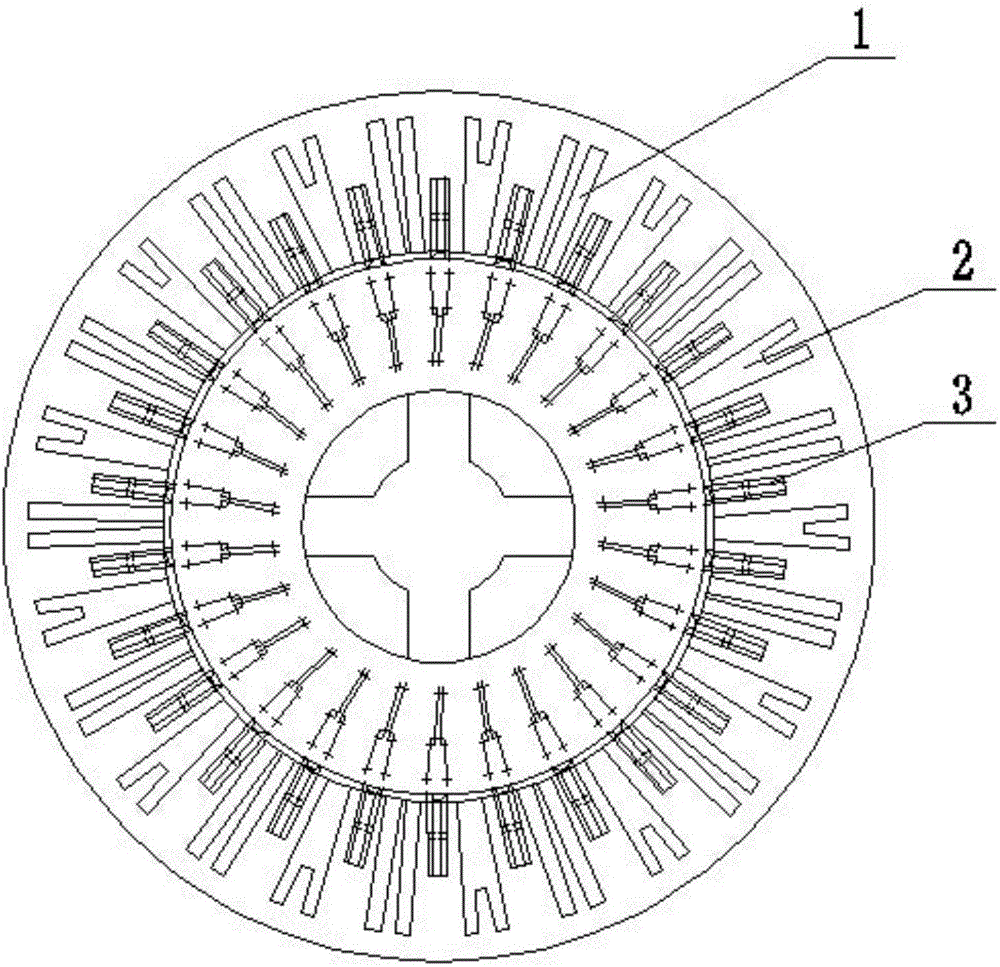

[0011] refer to figure 1 , the motor that facilitates fluid flow includes stator windings 3 and ventilation channel steels, wherein two rectangular ventilation channel steels 1 are arranged between two adjacent stator windings 3, and are adjacent to the two stator windings of the group A trapezoidal ventilation channel steel 2 is arranged between the two stator windings of the other group, and the width ratio of the upper half and the lower half of the trapezoidal ventilation channel steel 2 is 2:1. The upper half of the trapezoidal ventilation channel steel 2 is concave. The width of the upper half of the trapezoidal ventilation channel steel 2 is 20mm, and the width of the lower half is 10mm. The width of the rectangular ventilation channel steel 1 is 10mm.

[0012] Since the lower part of the trapezoidal ventilation channel steel 2 is narrowed, the flow range of the fluid is increased, the fluid flow velocity is accelerated, and the eddy current loss is also reduced due t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com