Mobile substation

A technology for moving substations and cables, applied in the field of substations, can solve the problems of local high temperature, transformer outage, and high temperature, and achieve the effects of weakening damage, effective temperature control, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

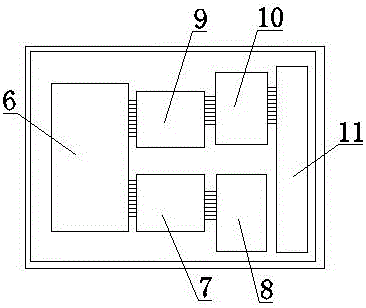

[0013] Such as Figure 1-2 In the shown embodiment, a mobile substation includes a sealed steel shell 1 and an arc-shaped shell 2. The inside of the sealed steel shell 1 is filled with a positive pressure of 0.02-0.03Mpa through a liquid nitrogen gas filling tank 12, and the circle The arc-shaped shell 2 is welded on the upper end of the airtight steel shell 1, and the inside of the airtight steel shell 1 is provided with a sound-insulating and moisture-proof inner panel 3, and the upper end of the sound-insulating and moisture-proof inner plate 3 is equipped with an air inlet 4 and an air outlet 5. An amorphous alloy transformer 6 is installed in the sound-proof and moisture-proof inner panel 3. One end of the amorphous alloy transformer 6 is connected to the high-voltage incoming and outgoing line cabinet 7 through a cable, and the high-voltage incoming and outgoing line cabinet 7 is connected to the high-voltage chamber 8 through a cable. The amorphous alloy transformer The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com