Diode-pumped alkali metal vapor high-pressure gain pool

A technology of gain pool and alkali metal, which is applied to laser components, laser components, electrical components, etc., can solve the problems of narrow absorption bandwidth and limit the development of lasers, and achieve the effect of ensuring no pollution and avoiding quartz cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

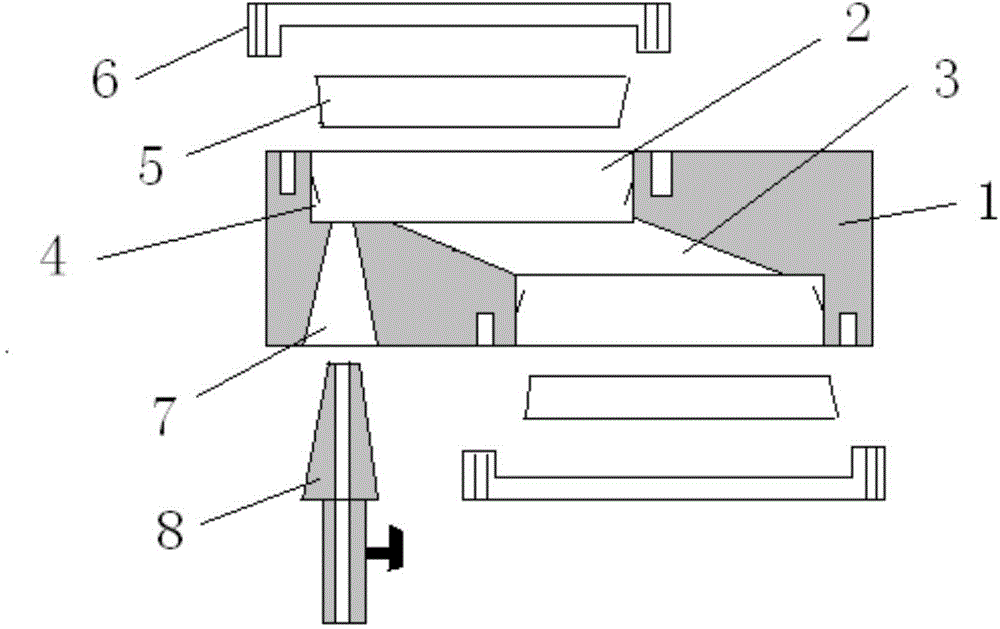

[0015] Such as figure 1 As shown, the whole set of gain cell includes: gain cell body, quartz window, window flange, and air hole piston. The main body of the gain pool is cylindrical, with a height of 100mm and a diameter of 120mm; a cylindrical pool is cut at the upper and lower ends of the cylinder, the diameter of the cylindrical pool is 40mm, and the axis of the two cylindrical pools is 60mm apart. The center of the main body of the gain pool is a symmetrical structure; the center of the two cylindrical pools is connected through a cylindrical through hole, and the axis of the cylindrical through hole connects the centers of the bottom surfaces of the two cylindrical pools and passes through the center of the main body of the gain pool. The cylindrical pool is provided with a buffer snap ring structure, and the buffer snap ring is an annular structure that is extended from the wall of the cylindrical pool and is coaxial with the cylindrical pool (the buffer snap ring is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com