Super-high-voltage vacuum insulation device

A technology of vacuum insulation and ultra-high voltage, which is applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., and can solve problems such as poor insulation of insulation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

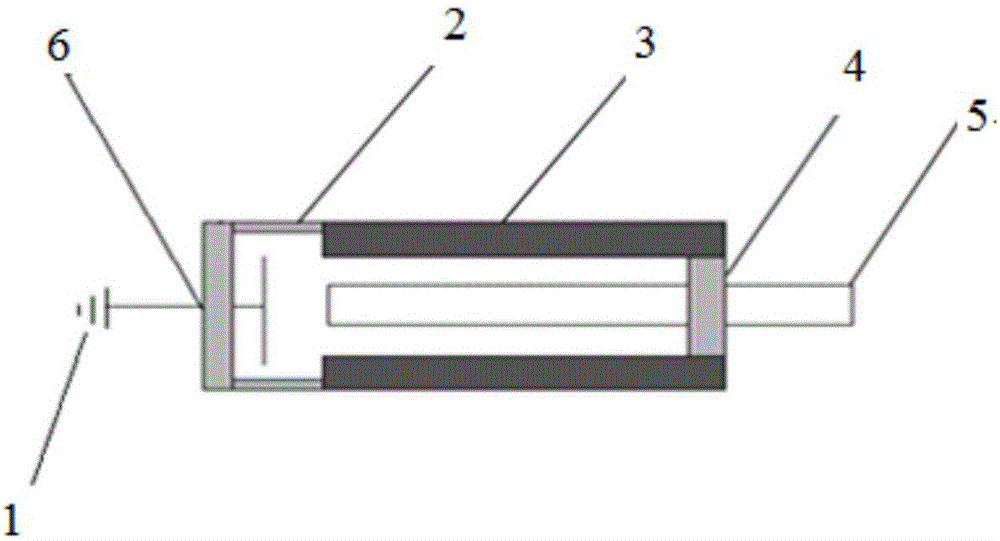

[0026] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0027] In the embodiment of the present invention, an ultra-high voltage vacuum insulation device is disclosed, which can insulate ultra-high voltages of 100,000 volts and above.

[0028] see figure 1 , the device of the present invention mainly includes a vacuum chamber. The entire vacuum chamber is made of insulating materials, such as polytetrafluoroethylene, ceramics, glass, rubber, etc. Although the entire vacuum chamber is made of insulating materials, the entire vacuum chamber is not limited to only one kind of insulating material, and different vacuum sections can be made of different insulating materials, which will be introduced in detail later.

[0029] In addition, the size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com