Weld image feature point extraction method based on laser vision sensor

An image feature point, visual sensor technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problem of cumbersome image feature point extraction algorithm, improve efficiency, etc., to simplify the amount of calculation and complexity, improve real-time performance , the effect of reducing redundant information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

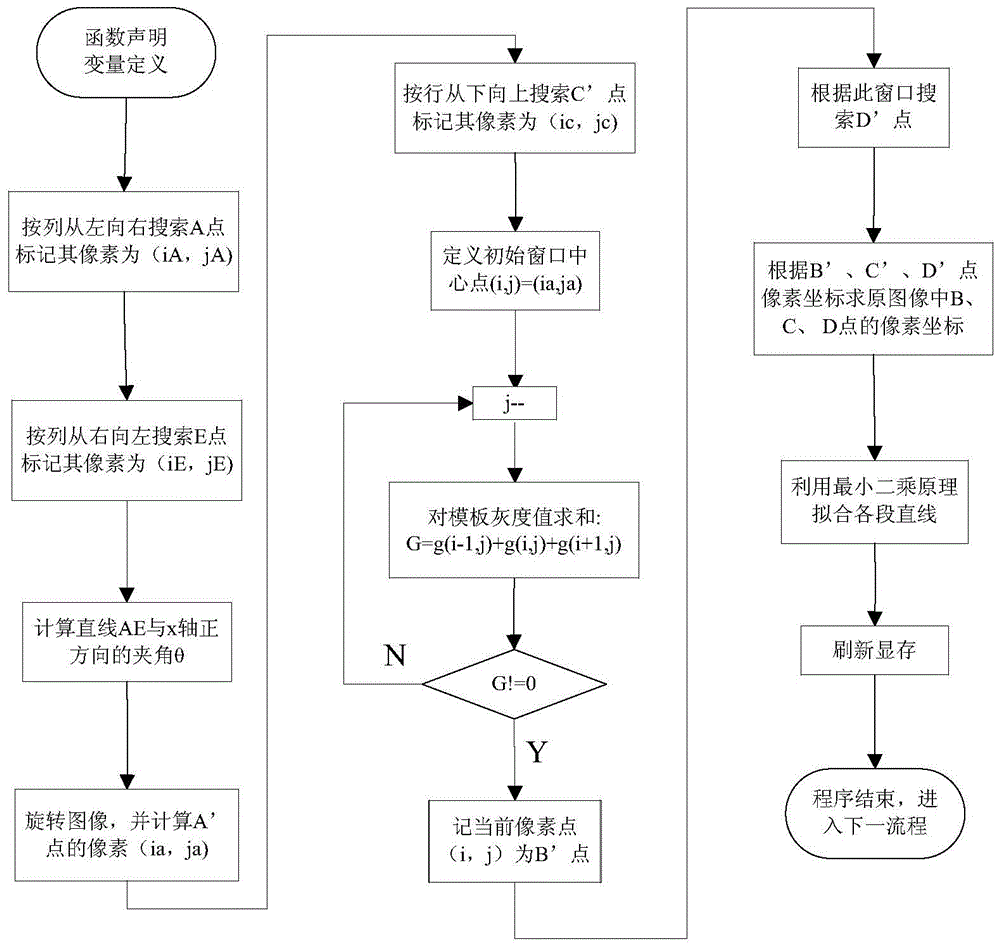

[0017] Such as Figure 1-3 As shown, a laser vision sensor-based weld image feature point extraction method includes the following specific steps:

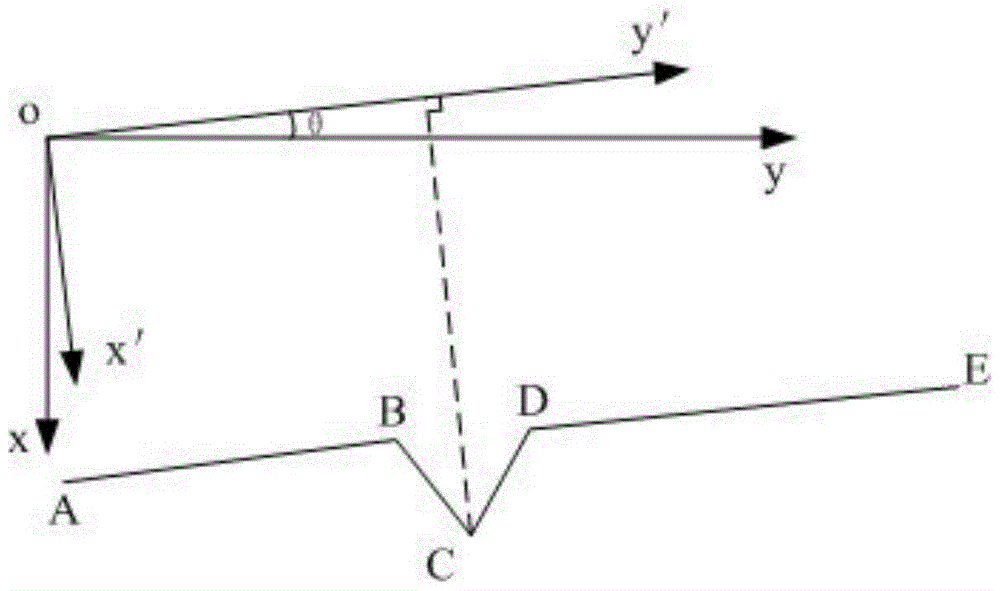

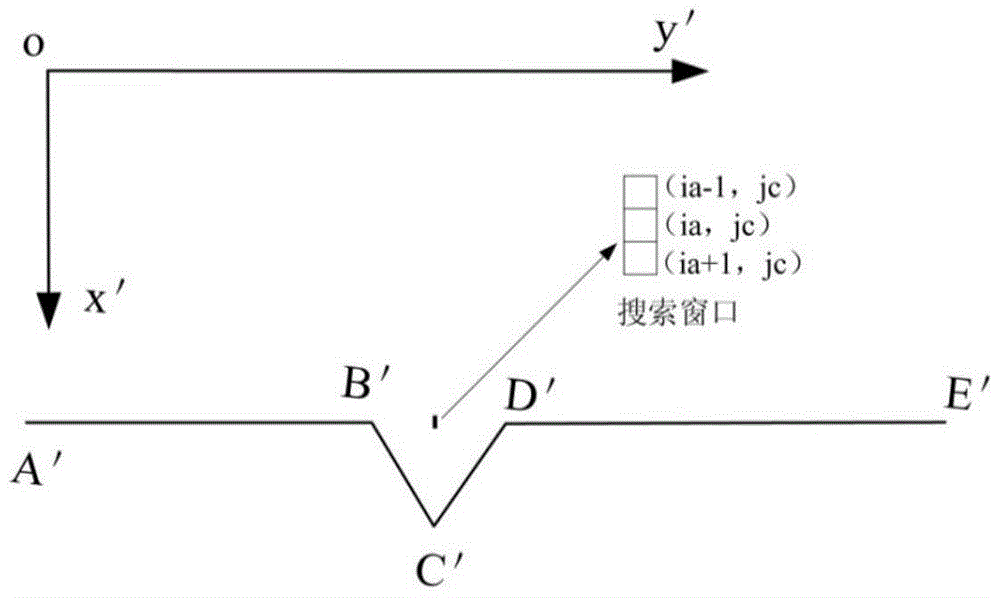

[0018] 1. After thinning the image, the obtained laser stripe center line has five feature points (A, B, C, D, E) that need to be extracted, and define the coordinate system where they are located, first from left to right, from top to bottom Search for the first non-zero gray value point successively, this point is recorded as point A, and its pixel point is marked as (iA, jA); search for the first non-zero gray value point successively from right to left, top to bottom , this point is recorded as point E, and its pixel is marked as (iE,jE);

[0019] 2. Use the rotation algorithm to rotate the laser stripe image to the horizontal direction, the rotation angle is θ, and the coordinate system afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com