Identification method of buckling of band steel

A technology for steel bending and identification strips, which is applied in the field of online identification, can solve problems such as missed detection of bending, lower strip yield, and difficult causes, and achieve the effect of enhancing contrast, improving image clarity, and obvious contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The method for identifying steel strip warpage according to the present invention will be further explained and described in conjunction with the accompanying drawings and specific embodiments below, but the explanation and description do not constitute undue limitations on the technical solution of the present invention.

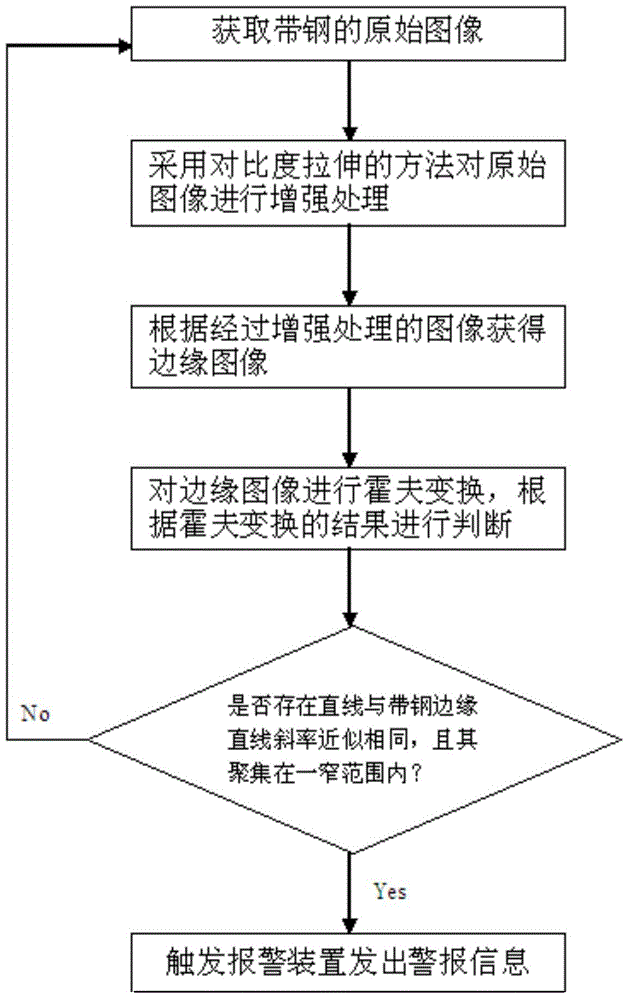

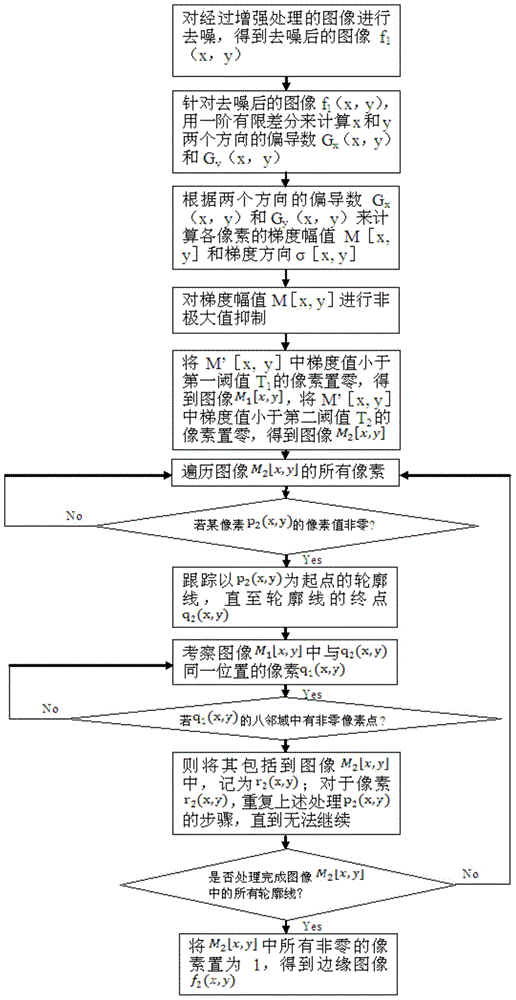

[0063] figure 1 It shows the process flow of the method for identifying steel strip warpage according to the present invention in an implementation manner. and figure 2 Then it shows the process flow of step (3) in the method for identifying steel strip warpage according to the present invention under one embodiment.

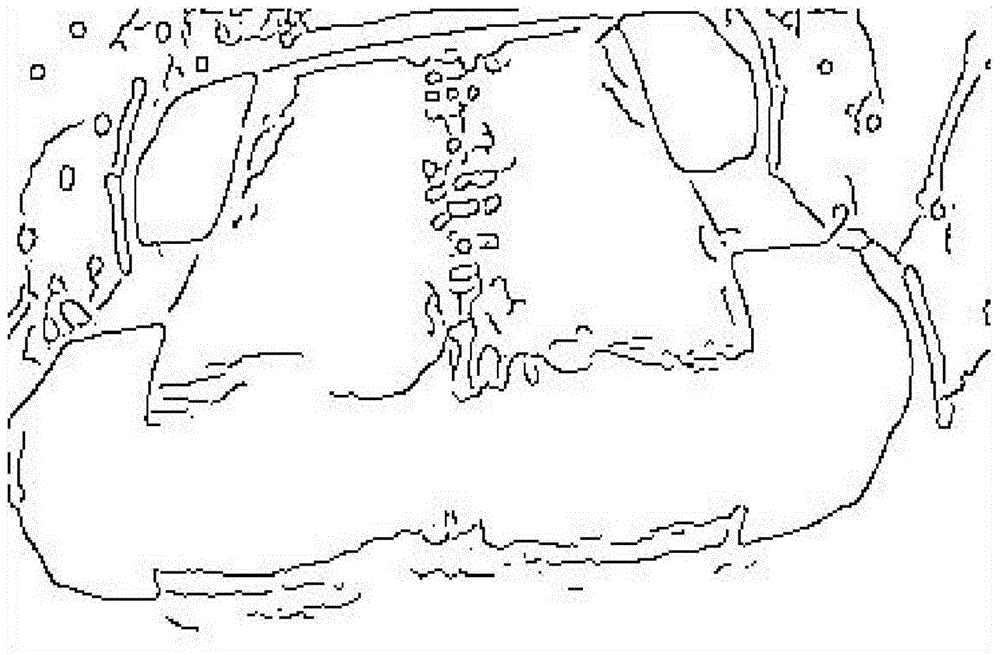

[0064] image 3 It is the edge image obtained after step (3) processing in the method for identifying steel strip warpage according to the present invention.

[0065] Such as figure 1 and figure 2 As shown, taking the strip steel running at high speed in the annealing furnace on a certain production line as an example, the metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com