Mining-affected coal seam floor water inrush simulation testing system

A technology of coal seam floor water inrush and simulation test system, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of water pump motor, mechanical seal damage, pressure instability, high maintenance costs, etc., to achieve a high degree of automation, sealing Good performance and safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

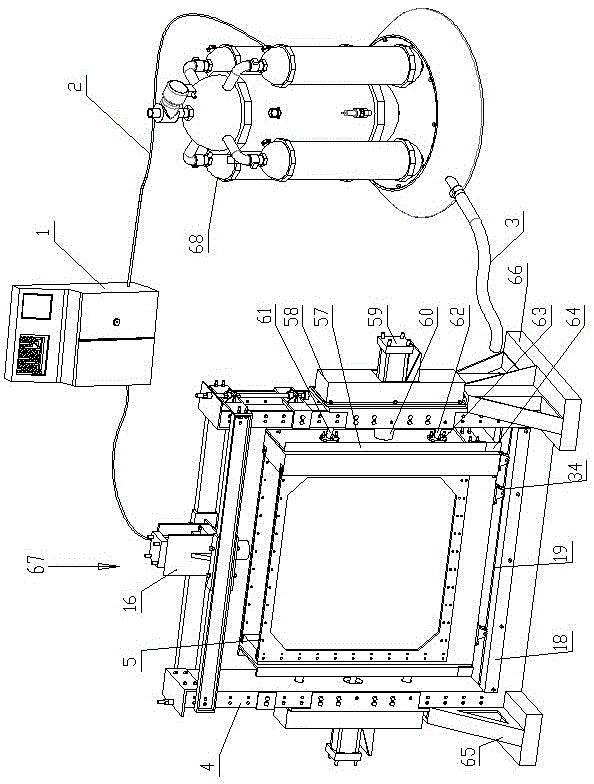

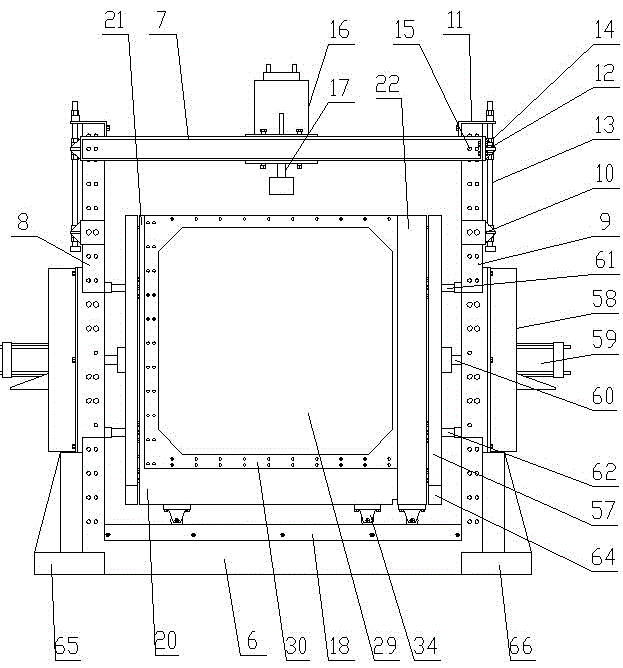

[0032] Such as Figure 1-8 As shown, the water inrush simulation test system for the coal seam floor affected by mining includes a simulation test device 67, an operation console 1 and a water pressure control device 68. The device 68 is connected, and the water pressure control device 68 is connected with the simulation test device 67 through the water inlet pipe 3 .

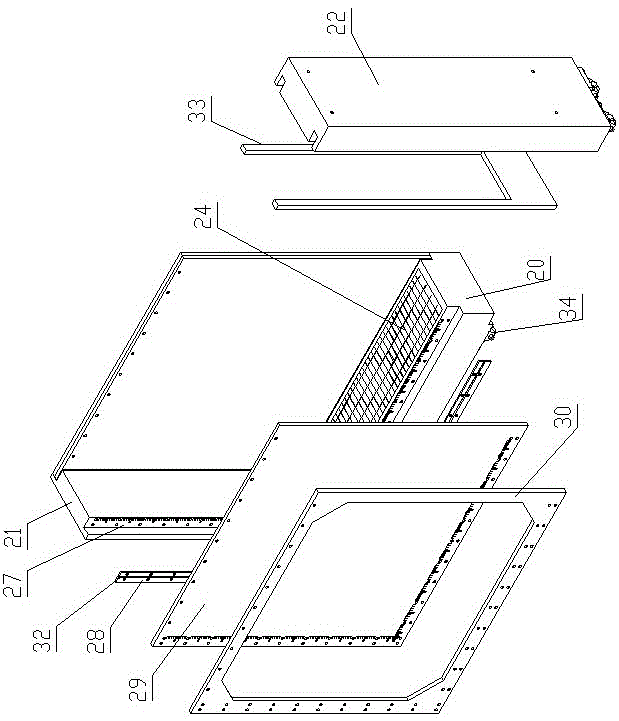

[0033] The simulation test device 67 includes an outer frame 4 and a test bench 5 arranged in the outer frame 4, the outer frame 4 includes a lower frame 6, an upper frame 7, a left frame 8 and a right frame 9, the lower frame 6 and the upper frame 7 are all horizontally arranged, The left frame 8 and the right frame 9 are all vertically arranged, the left and right ends of the lower frame 6 are respectively fixedly connected with the lower end of the left frame 8 and the lower end of the right frame 9, and the left frame 8 and the upper part of the right frame 9 are all provided with a fixed mounting frame 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com