Multifunctional uniaxial tensile test device for microstructure in-situ online observation

A microstructure and uniaxial stretching technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as potential safety hazards, inability to obtain microstructure change data, etc., and achieve high reliability. , Ingenious design, easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

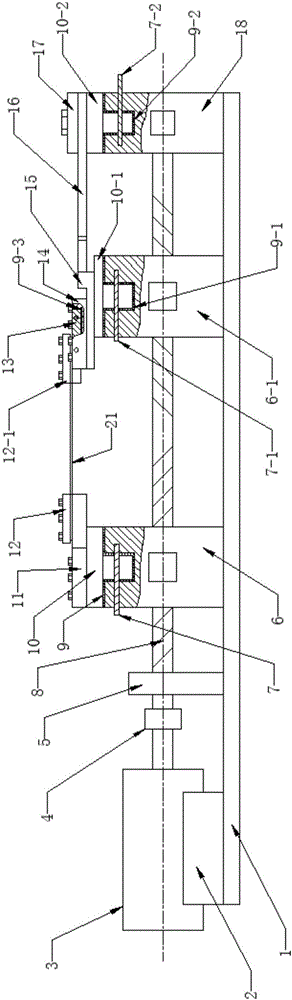

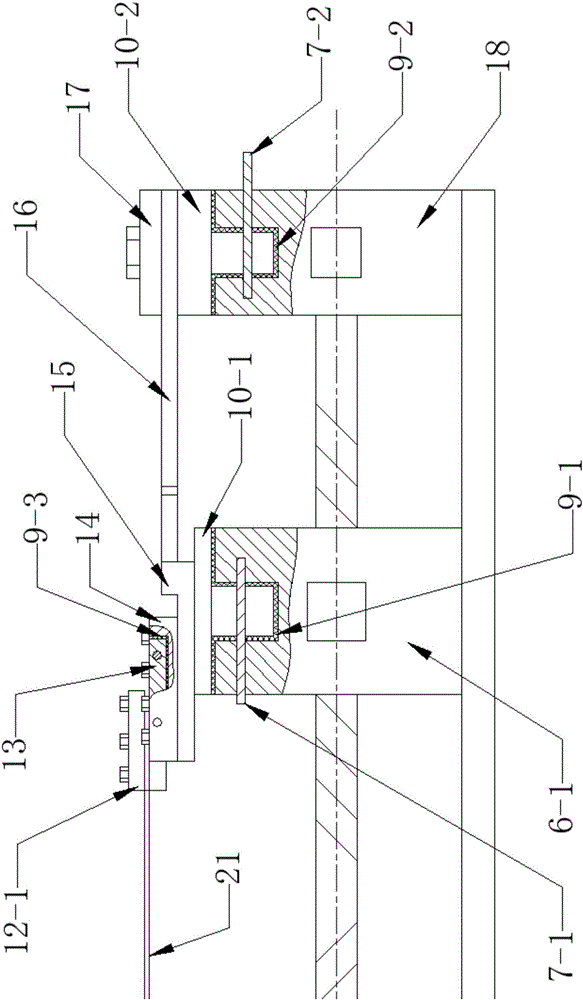

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

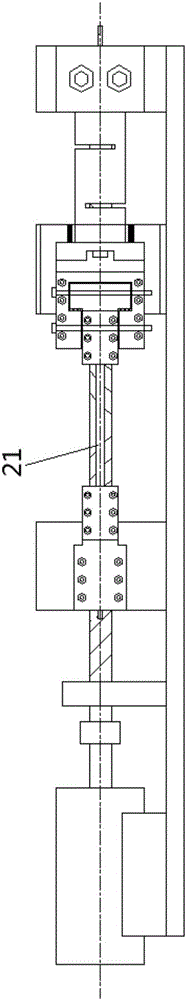

[0031] Such as Figure 1-Figure 3 As shown, the multifunctional uniaxial tensile test device for in-situ on-line observation of microstructure can realize in-situ tension when the sample is energized, the sample is not energized, the sample is placed horizontally and loaded, and the sample is placed sideways. The test consists of four parts: frame, power transmission, clamping and force measurement.

[0032] The frame is composed of base plate 1, motor holder 2, guide rail 19, 19-1;

[0033] Wherein, the motor fixing seat 2 is installed on the bottom plate 1, the guide rails 19 and 19-1 are parallel to the axis of the motor 3, and the guide rails 19 and 19-1 are symmetrically arranged in guide rail grooves on both sides of the axis of the motor 3.

[0034] The power transmission part includes a motor 3, a shaft coupling 4, a screw 8, a screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com