Frequency conversion and energy conservation control method for main suction fan of sintering machine

A main exhaust fan, energy-saving control technology, applied in the direction of furnace control devices, furnace types, furnaces, etc., can solve problems such as large fluctuations, limited energy-saving space for control methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

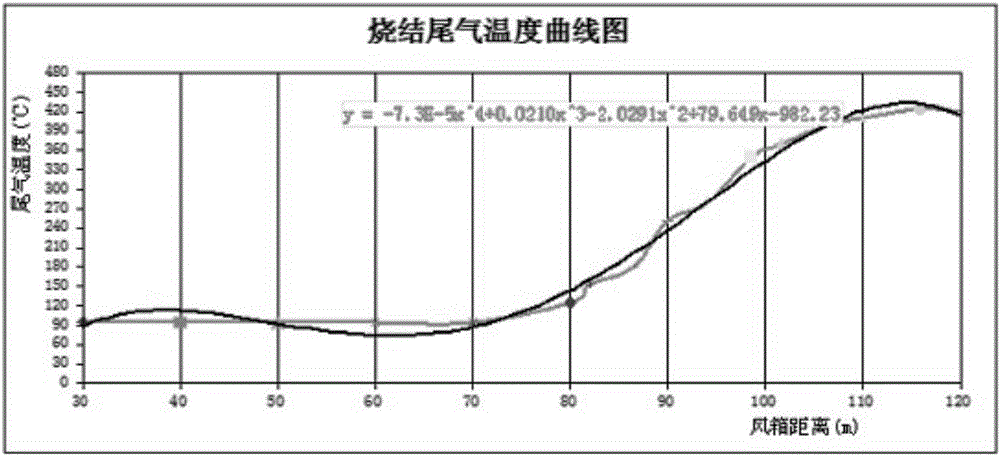

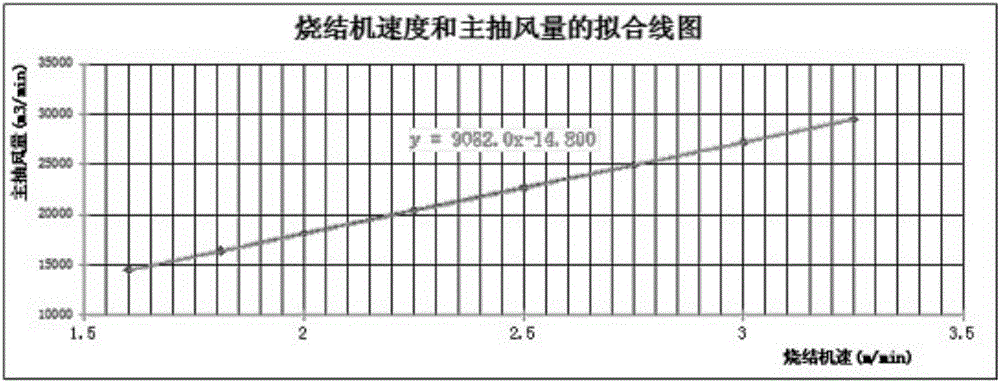

[0049] The following will combine Figure 1 to Figure 5 The frequency conversion energy-saving control method of the main exhaust fan of the sintering machine provided by the present invention is described in detail, which is an optional embodiment of the present invention. Make revisions and polish.

[0050] Please refer to Figure 5 , the present invention provides a frequency conversion energy-saving control method for the main exhaust fan of a sintering machine, comprising the following steps:

[0051] Real-time collection of the temperature of each bellows;

[0052] Then, at each moment:

[0053] S1: According to the collected temperature and the corresponding bellows position, the function relationship curve between the bellows temperature and the bellows position is obtained by fitting;

[0054] In an optional embodiment of the present invention, for each air box, six temperature sensors are arranged to detect its temperature, and the six temperature detectors are l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com