A New Automatic Adoption System of Bag Method

A bag method, automatic technology, applied in the direction of sampling devices, etc., to save waiting time, ensure purity, ensure sampling accuracy, stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

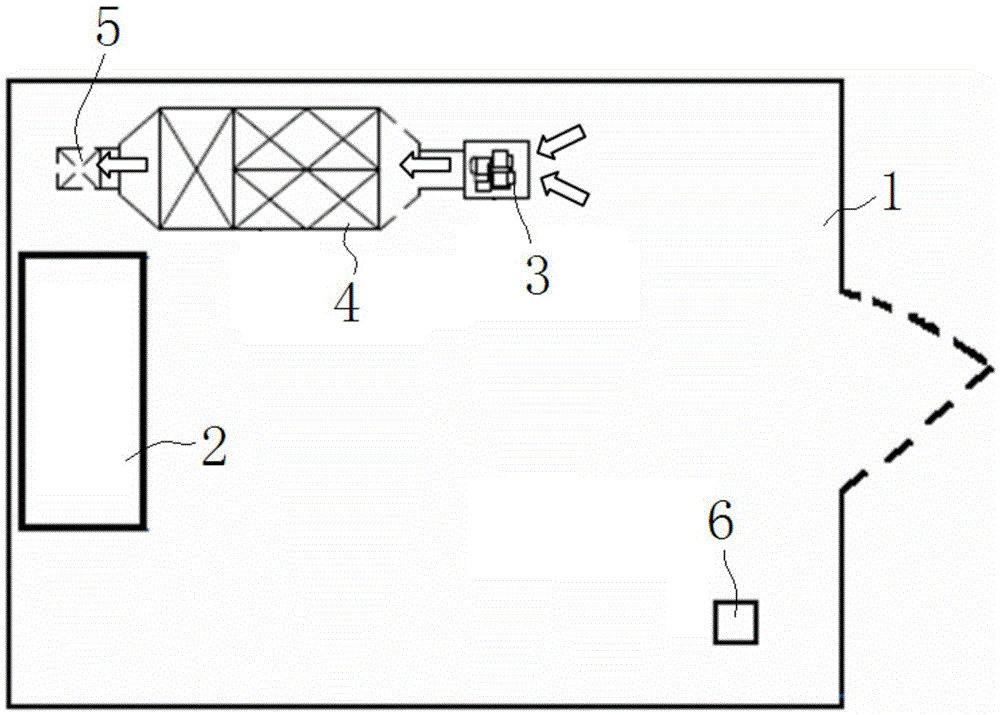

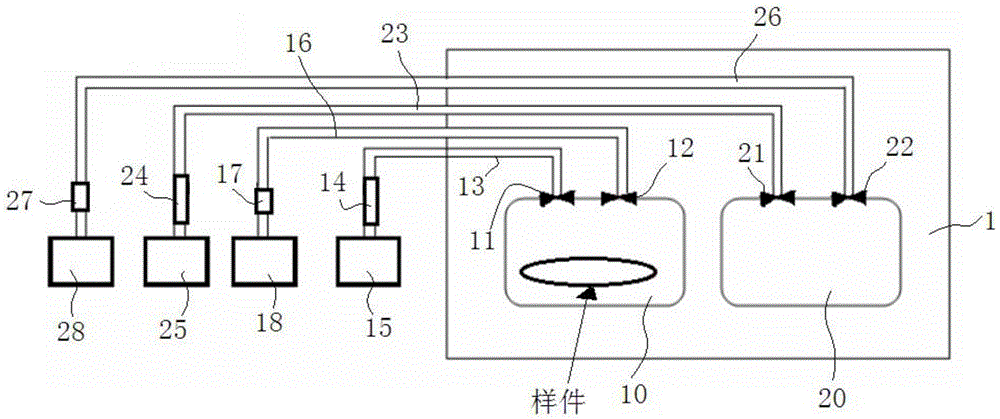

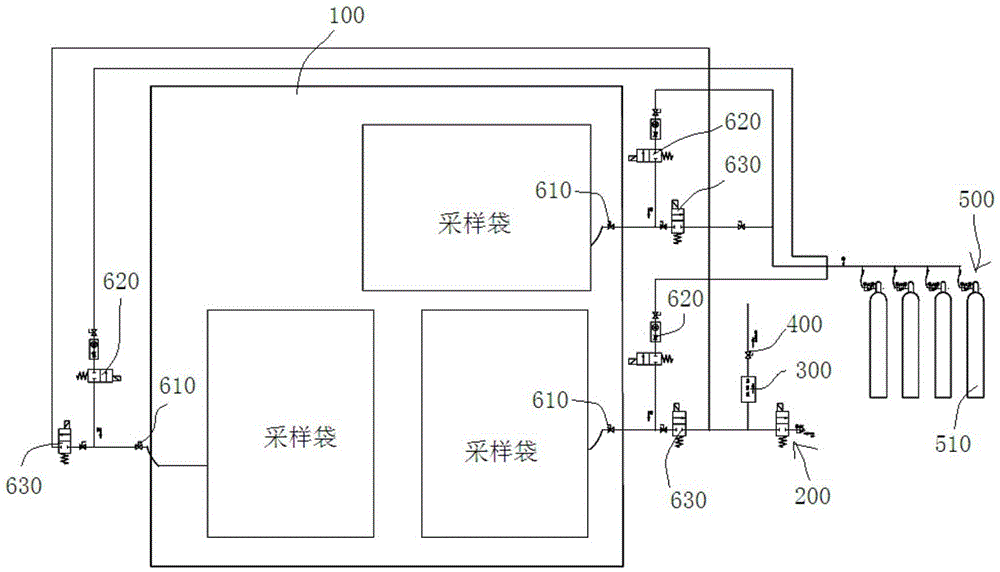

[0037] see image 3 and Figure 4 , the new bag method automatic adopting system shown in the figure includes a sampling bin 100. The sampling bin 100 is provided with a constant temperature and humidity unit, an inlet fan, and a filter, and an air outlet and an outlet are provided on the wall of the bin body. The air outlet, the outlet of the fan inlet is connected with the outlet of the filter, and the outlet of the filter 4 is connected with the air outlet (not shown in the above figure, see figure 1 ); heating components in the sampling chamber 100 (not shown in the figure). The heating part is controlled by the PLC controller to realize automatic heating. After the temperature reaches the target value, it will automatically keep warm, without the need for personnel to monitor the operation, saving personnel from waiting for a long time.

[0038] The new bag method automatic adopting system includes compressed air solenoid valve 200, vacuum pump 300, vacuum valve 400, ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com