Oil path sealing device and processing method thereof

A technology of sealing device and oil circuit, which is applied in the field of vehicle parts, can solve the problems of rubber oil seal ring, oil leakage and oil leakage, etc., and achieve the effect of enhancing the sealing effect, increasing the service life, and enhancing the degree of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

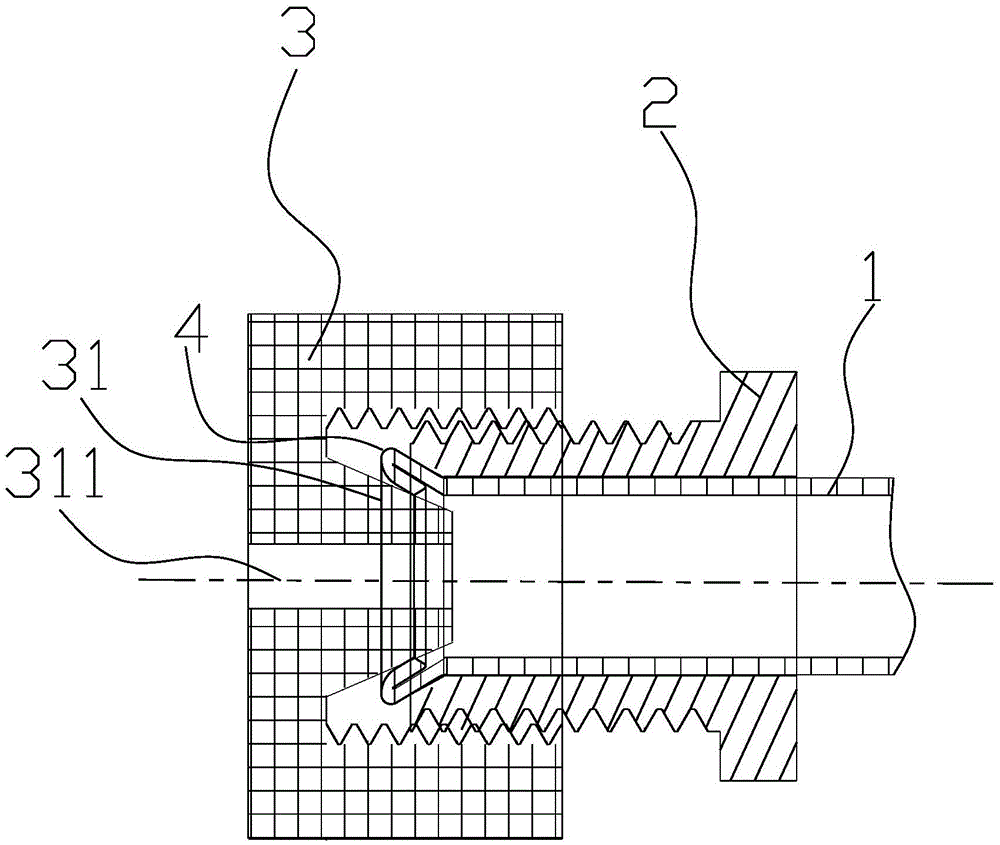

[0045] like Figure 2-3 As shown, the pipeline 1 is provided with a trumpet head 4, and the plug 3 is provided with a frustum-shaped blocking block 31, and the small circle diameter of the blocking block 31 is smaller than the diameter of the trumpet head, and the blocking block The diameter of the great circle of 31 is greater than the diameter of the horn head;

[0046] The blocking block 31 is closely attached to the inner side of the horn head through the cooperation of the fastening bolt and the plug, so that the blocking block intersects with the inside of the pipeline to achieve a sealing effect.

[0047] The horn head is divided into an inner layer 42 and an outer layer 41, the outer layer 41 is closely attached to the inner layer 42, and the blocking block is closely attached to the plug through the cooperation of the fastening bolt and the plug. on the inner layer. Due to the tightening effect of the fastening bolts, the single-layer horn head is easy to wear and c...

Embodiment 2

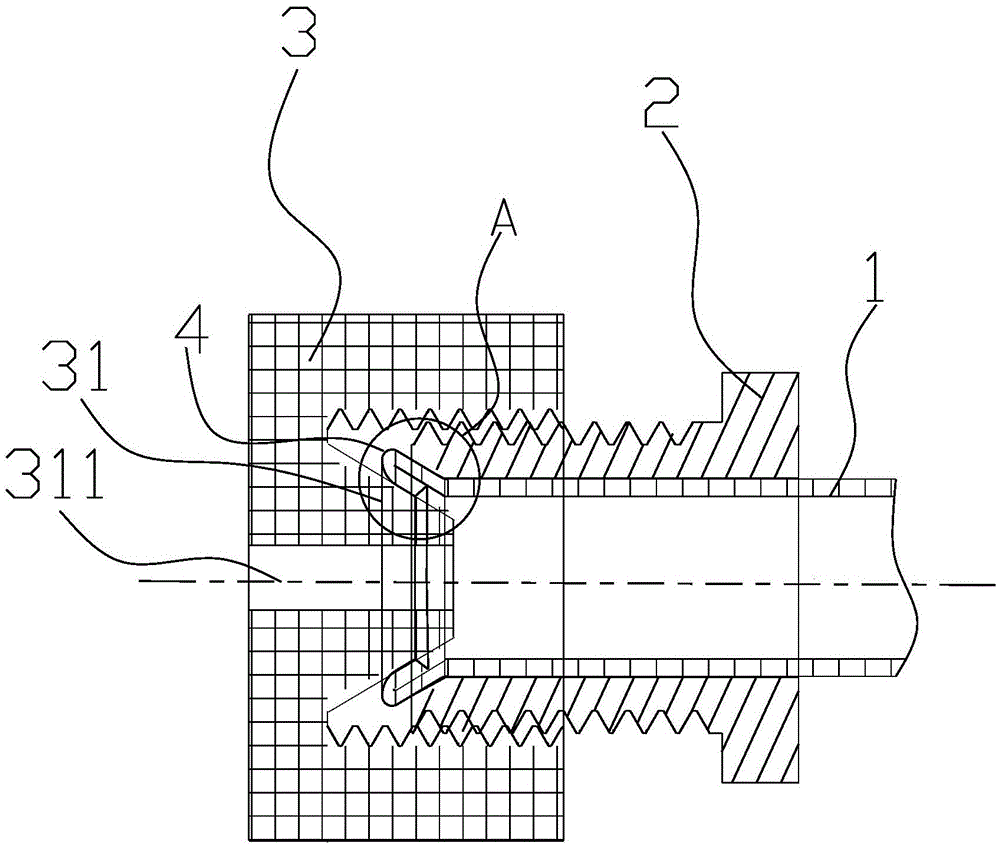

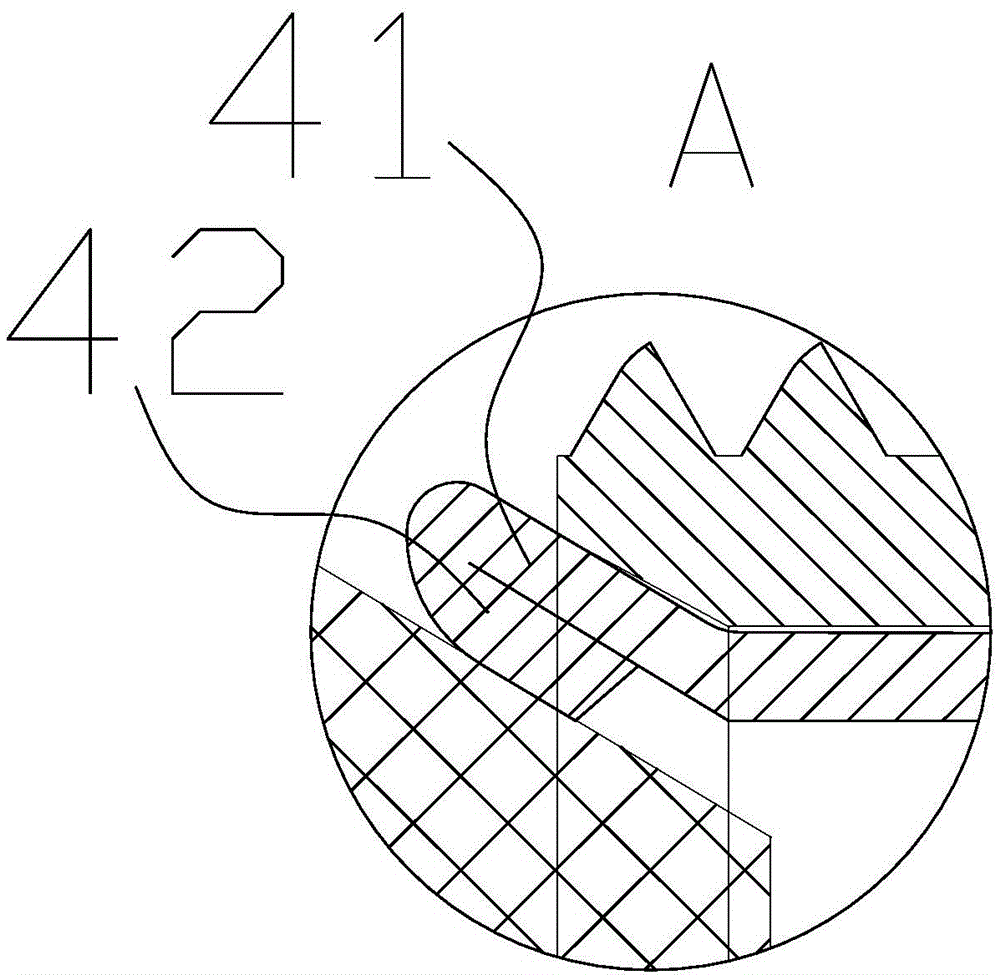

[0049] like Figure 4-5 As shown, the end is divided into an inner layer and an outer layer, and an angle is formed between the outer layer and the inner layer, so that the inner layer is elastic when it fits the block, making the fit more tightly and the sealing effect better .

[0050] A frustum-shaped blocking block is arranged inside the plug, the diameter of the small circle of the truss is smaller than the diameter of the horn head, and the diameter of the large circle of the truss is larger than the diameter of the horn head, so that the block is in contact with the pipeline. There is a cross inside to play a sealing effect.

[0051] The blocking block is closely attached to the end point of the inner layer through the cooperation of the fastening bolt and the plug to form a seal to prevent oil leakage. Under the premise of the same strength, the line seal is stronger than the surface seal, and the sealing effect is better.

Embodiment 3

[0053] like Figure 6-7 As shown, the end is divided into an inner layer and an outer layer, and an angle is formed between the outer layer and the inner layer; resulting in the inner layer having the function of a shrapnel, which can be used when the online seal or the surface seal is not tightly sealed. to a certain compensation

[0054] A frustum-shaped blocking block is arranged inside the plug, the diameter of the small circle of the truss is smaller than the diameter of the horn head, and the diameter of the large circle of the truss is larger than the diameter of the horn head;

[0055] The side of the blocking block is provided with several platform-shaped clamping positions for clamping the inner layer.

[0056] The purpose of setting the platform-shaped locking position is mainly to slow down the friction between the inner layer and the blocking block, and prolong the service life of the sealable device. When in use, the horn head can be placed at the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com