Engine oil level gauge installation structure of engine

An engine oil and installation structure technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of insufficient compact structure, inconvenience, multiple installations, etc., and achieve the effect of compact structure, convenient installation and improved sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

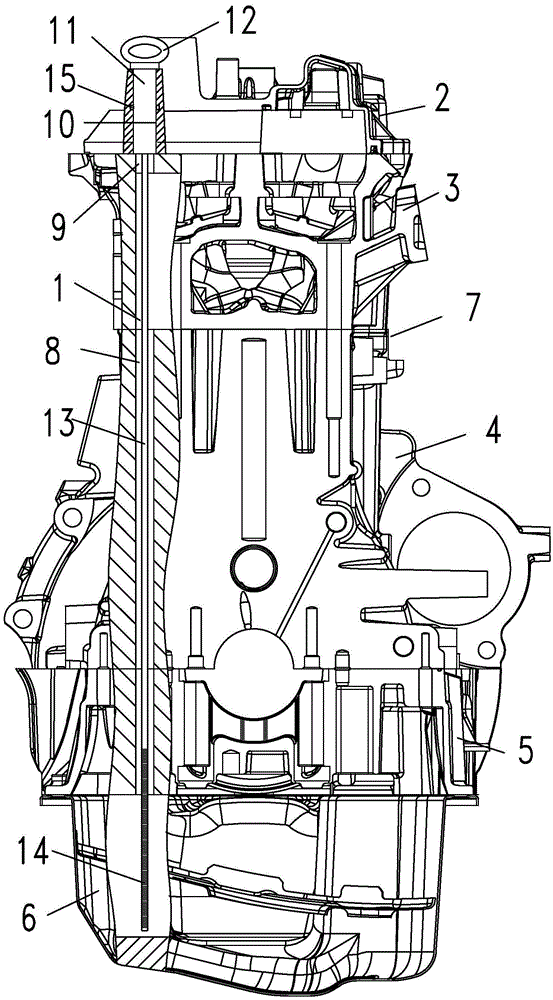

[0017] as attached figure 1 Shown: a kind of installation structure of engine oil dipstick, comprising: engine oil dipstick 1, the engine body 7 that is made of cylinder head cover 2, cylinder head 3, cylinder block 4, crankcase 5 and oil sump 6; There is an oil return passage 8 that runs through the cylinder block 4 and the crankcase 5; the cylinder head 3 is provided with a through hole 9 whose lower end is opposite to the upper end of the oil return passage 8; the cover 2 of the cylinder head 3 is provided with a lower end and an upper end of the through hole 9 Connected socket 10; the lower end of the oil dipstick 1 extends into the oil pan 6 through the socket 10, the through hole 9 and the oil return channel 8.

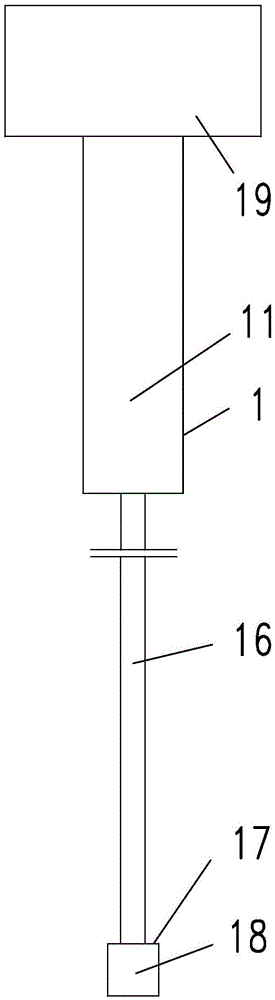

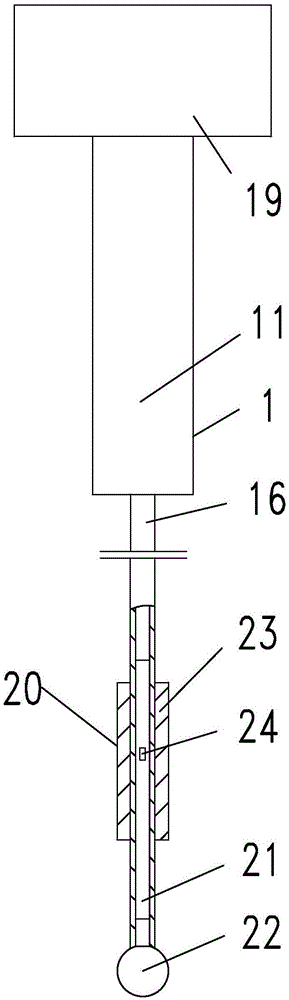

[0018] In this embodiment, the oil dipstick 1 includes: an insertion pipe 11 whose outer diameter fits with the diameter of the socket 10 , a pull ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com