Process afterheat classification utilization system and purpose thereof

A heat classification and waste heat technology, applied in heat pumps, lighting and heating equipment, sustainable manufacturing/processing, etc., can solve the problem of less circulation system and achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

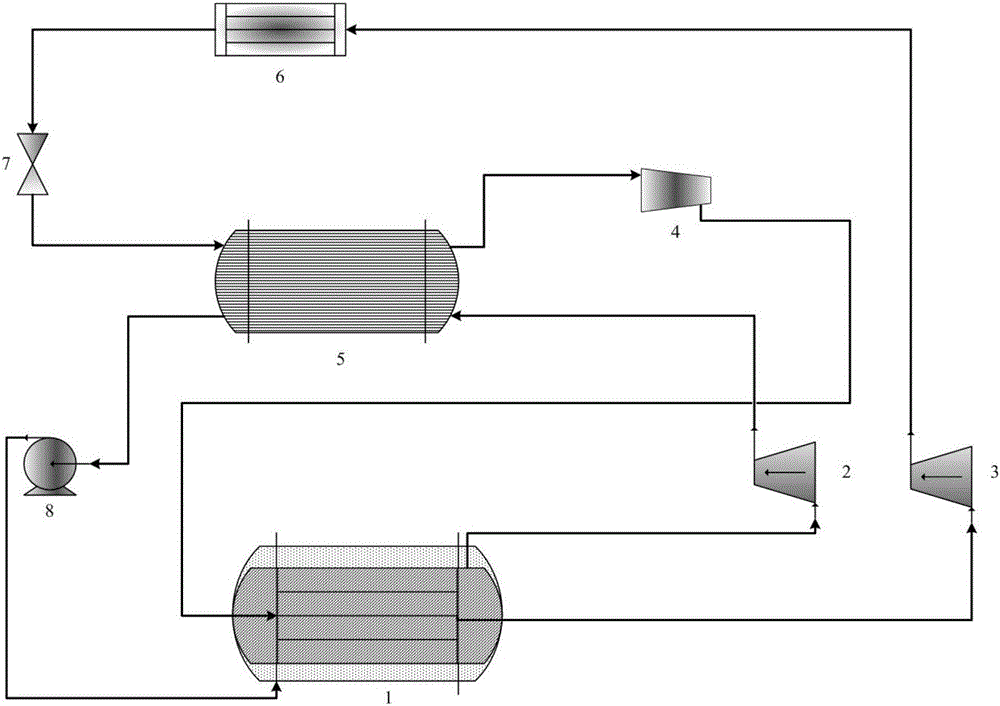

[0061] use figure 1 The equipment uses the waste heat of the process system to supply heat to the evaporation heating device 1. The working fluid A is R245fa, and the fluid B is E-HFO-1336. After the two pass through the evaporation heating device 1, the temperatures of the working fluids A and B are both 213°C, and the temperatures of the working fluid B before and after condensation are 161°C and 27°C respectively. . The energy released by the condenser 6 can meet the needs of different load processes. In addition, the working pressure and temperature of components such as the compressor 4 and the turbine power generation device 2 and 3 are all within the normal range that the equipment can be used for. The specific parameters and results are shown in Table 1. In the table, T represents temperature, P represents pressure, Q represents heat absorbed or released, and W represents external work.

[0062] working fluid

[0063] Examples show that under the working c...

Embodiment 2

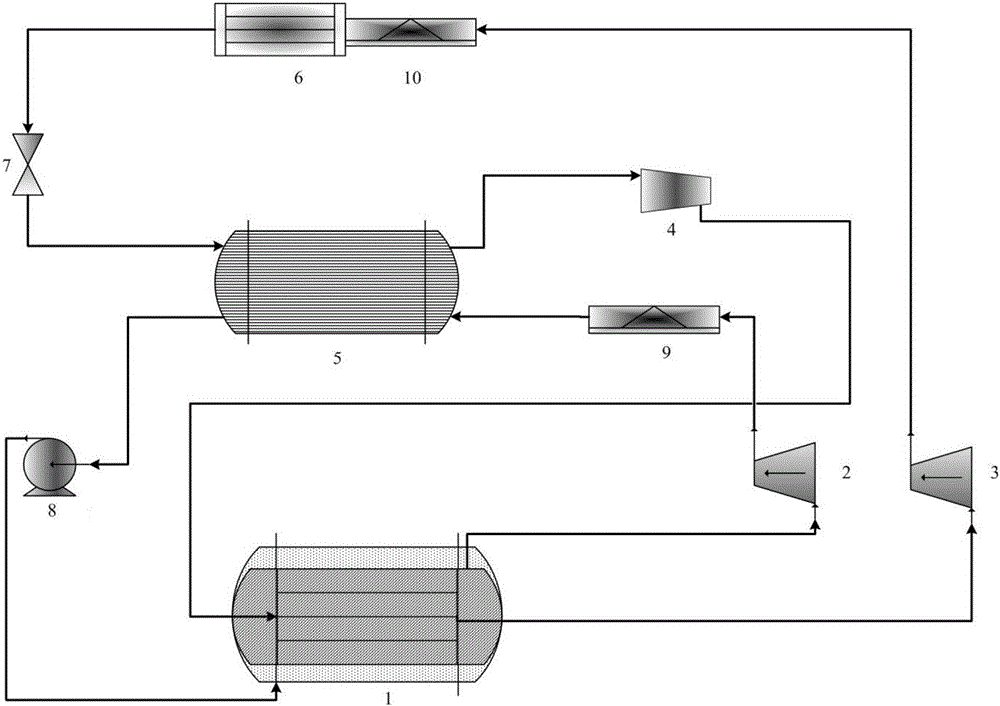

[0065] use figure 2 The equipment utilization process waste heat graded utilization scheme utilizes the waste heat of the process system to supply heat to the evaporation heating device 1 . The working fluid A is R245fa, and the fluid B is E-HFO-1336. After the two pass through the evaporation heating device 1, the temperatures of the working fluids A and B are 213°C and 153°C respectively, and the temperatures of the working fluid B before and after condensation are respectively 161°C and 27°C. The two streams of working fluid enter the heat exchanger 5 or the condenser 6 after passing through the high-grade heat classification utilization devices 9 and 10, and the energy released by the condenser 6 can meet the needs of different load processes. In addition, the working pressure and temperature of components such as the compressor 4 and the turbine power generation device 2 and 3 are all within the normal range that the equipment can be used for. The specific parameters an...

Embodiment 3

[0069] use figure 2The equipment utilization process waste heat graded utilization scheme utilizes the waste heat of the process system to supply heat to the evaporation heating device 1 . The working fluid A is R123, and the fluid B is R124. After the two pass through the evaporation heating device 1, the temperatures of the working fluids A and B are 213°C and 120°C respectively. The two streams of working fluid enter the heat exchanger 5 or the condenser 6 after passing through the high-grade heat classification utilization devices 9 and 10, and the energy released by the condenser 6 can meet the needs of different load processes. In addition, the working pressure and temperature of the compressor 4 and the turbine power generation device 2, 3 and other components are all within the normal range that the equipment can be used. The specific parameters and results are shown in Table 3.

[0070]

[0071]

[0072] The example shows that under the working conditions of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com