Kitchen grease interceptor

An oil well and kitchen technology is applied in the field of kitchen sewer purification devices to achieve the effect of optimizing the structure and simplifying the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

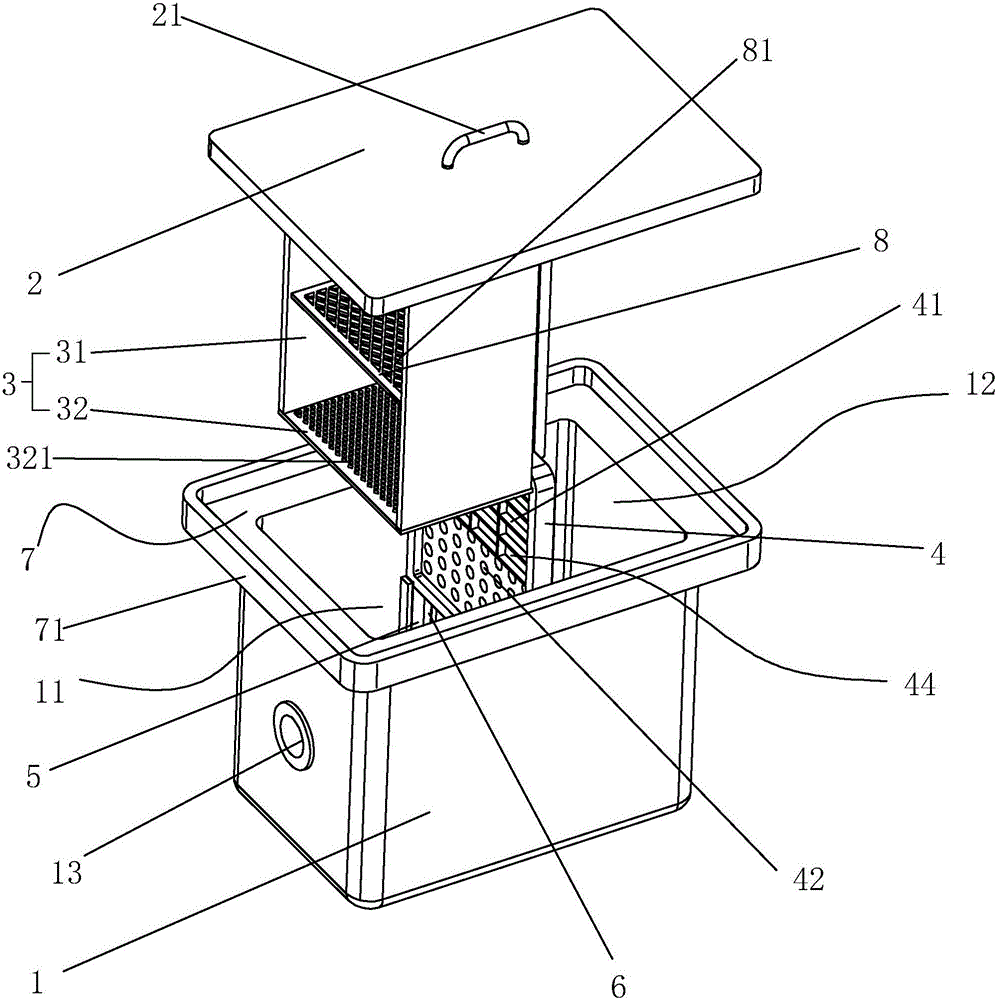

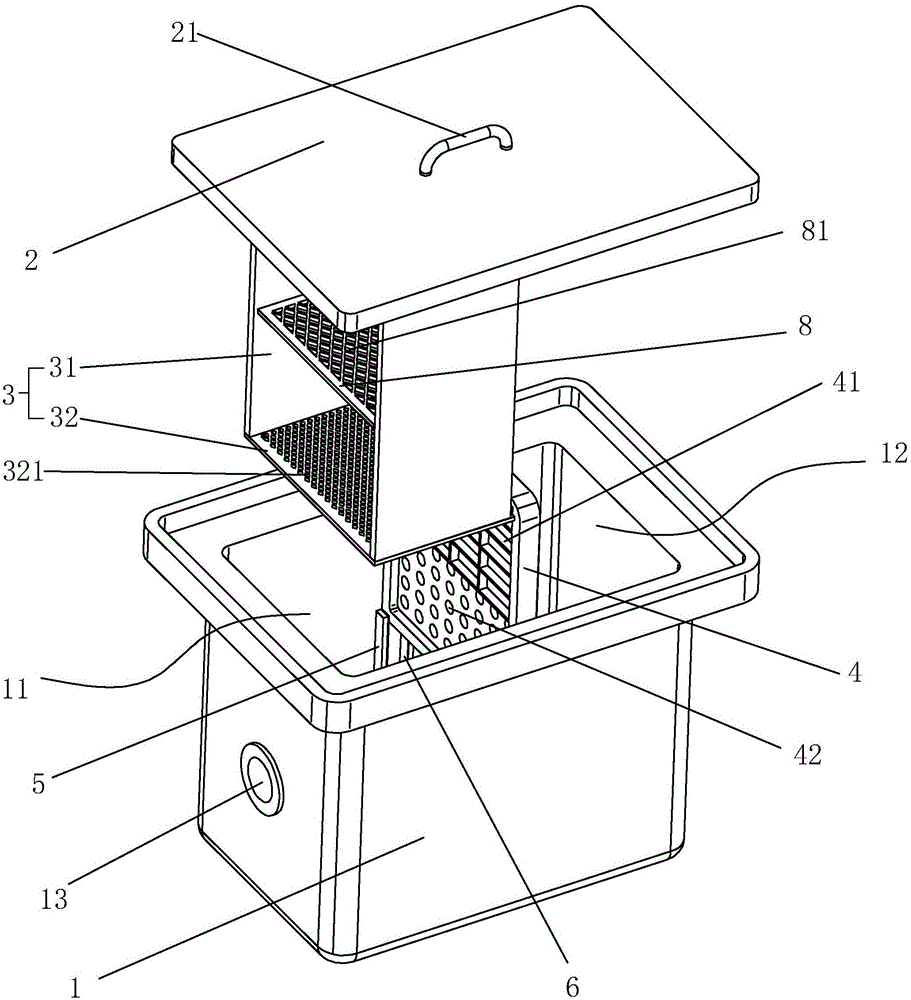

Embodiment 1

[0034] Embodiment one, combining figure 2As shown, the inner wall of the barrel body 1 is relatively provided with two chute 5, and the chute 5 is slidably connected with the oil separator 4, when the oil separator 4 is placed in the barrel body 1, the Barrel body 1 is divided into independent clean water room 12 and sewage room 11, and corresponding clean water room 12 and sewage room 11 are respectively provided with clean water outlet 14 and sewage inlet 13, and sewage inlet 13 is then connected to the water outlet of domestic sink, so The water purification outlet 14 described above is connected to the sewer inlet, and the chute 5 is provided with a gasket 6 on one side of the water purification room 12, the gasket 6 is made of rubber material, and the gasket 6 is arranged along the length direction of the chute 5 And fixedly connected with the chute 5, the length of the sealing pad 6 is roughly half of the chute 5, and one end of the sealing pad 6 is connected to the bot...

Embodiment 2

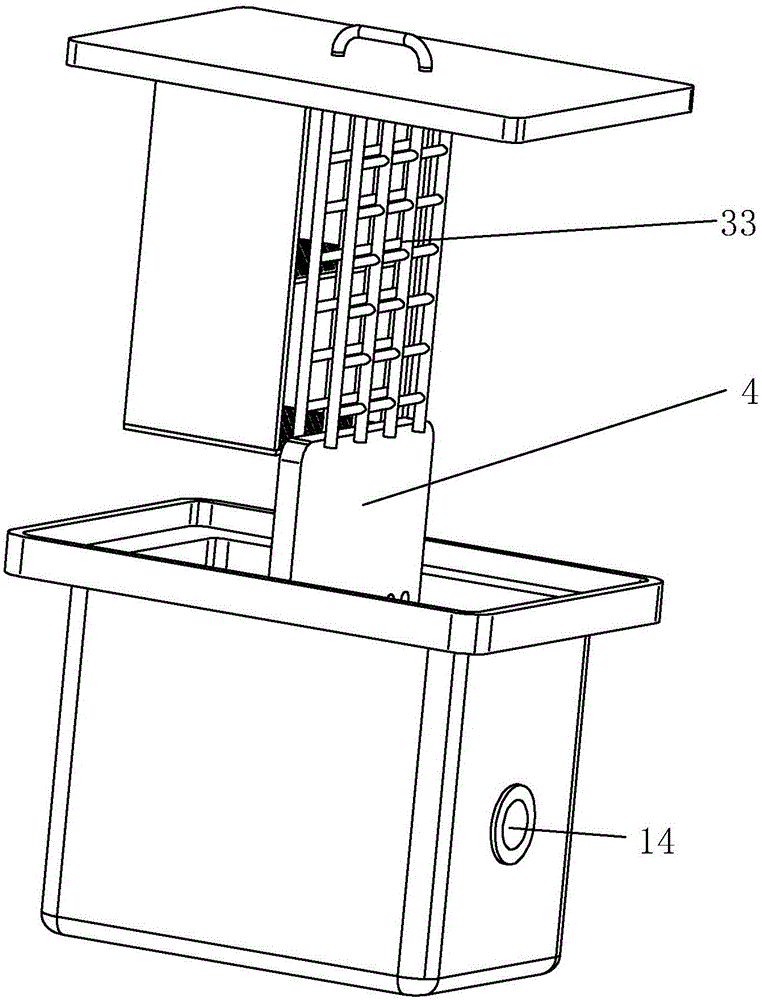

[0039] Embodiment two, such as Figure 3 to Figure 4 As shown, the oil separator 4 is provided with a number of positioning grooves 43 on one side of the clean water room 12, and the positioning grooves 43 are arranged along the depth direction of the barrel body 1, and all the positioning grooves 43 are gathered at the bottom of the oil separator 4. It is set at the middle position, the distance between the two positioning grooves 43 on the outermost edge is 1 / 2 of the total width of the oil separator 4, and the distance between two adjacent positioning grooves 43 is the same, and the reinforcing plate 33 is set It is a positioning strip one by one, and the positioning strip is matched with the positioning groove 43. The positioning strip is integrally connected to the connecting part 31. The connecting part 31 of this embodiment is two independent plates. Connected to the barrel cover 2, the other end is connected to both ends of the receiving plate 32. One end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com