Acid solution, device and process for cleaning sludge plate-frame dewatering filter cloth

A plate and frame filter press and plate and frame technology, applied in the field of plate and frame filter press, can solve the problems of non-adjustable cleaning liquid concentration, limited scope of application, and secondary pollution of the environment, so as to promote sludge conditioning and dehydration and realize environmental protection Utilization, equipment corrosion effect is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

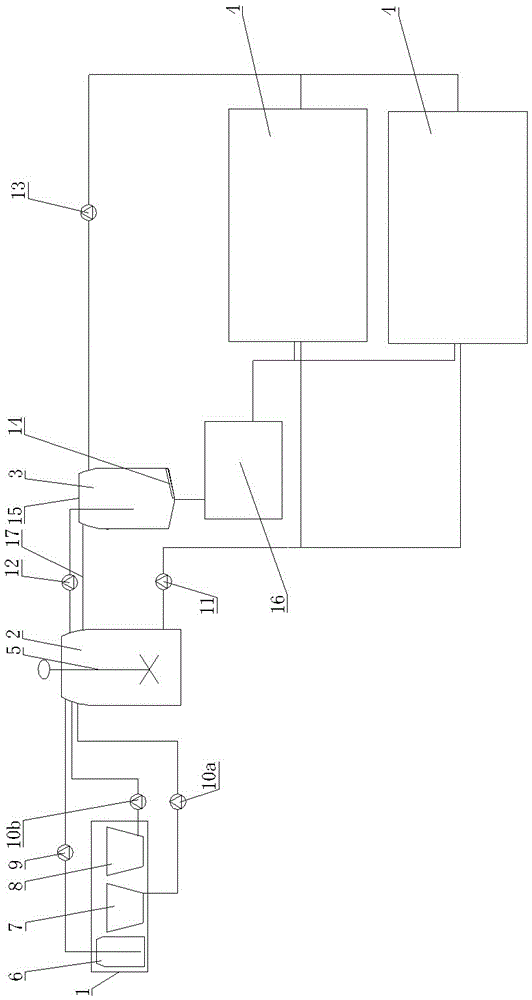

Image

Examples

specific Embodiment 1

[0048] Specific embodiment 1: A certain sludge deep dewatering project has two diaphragm plate and frame filter presses, the filter plate size of the plate and frame filter press is 2m*2m, and there are 115 filter plates. After using for a period of time, the filter cloth has obvious scale, the filter cloth hardens, the feed pressure rises rapidly to above 1.0MPa and the injection volume decreases obviously, indicating that the filter cloth of the table frame needs to be cleaned. The mass percentages of scale components were detected as follows: 32.5% calcium carbonate, 17.9% calcium hydroxide, 6.5% magnesium hydroxide, 21.6% iron hydroxide, 14.2% magnesium hydrogen phosphate, and 7.3% with unknown ingredients. The PLC controller starts the acid mixing process, and the acid liquid tank is injected with 0.3t of acetic acid (acetic acid content≥99.5%), 0.2t of oxalic acid (oxalic acid content≥99%), and 0.1t of citric acid (citric acid content≥99%) through the delivery device. Af...

specific Embodiment 2

[0049] Specific embodiment 2: A certain sludge deep dewatering project has two diaphragm plate and frame filter presses, the filter plate size of the plate and frame filter press is 1.5m*1.5m, and there are 110 filter plates. After using for a period of time, the filter cloth has obvious scale, the filter cloth hardens, the feed pressure rises rapidly to above 1.0MPa and the injection volume decreases obviously, indicating that the filter cloth of the table frame needs to be cleaned. The mass percentages of scale components were determined to be 30.8% calcium carbonate, 16.6% calcium hydroxide, 6.4% magnesium hydroxide, 23.8% iron hydroxide, 12.5% magnesium hydrogen phosphate, and 9.9% with unknown ingredients. The PLC controller starts the acid mixing process, and the acid liquid tank is injected with 0.4t of acetic acid (acetic acid content≥99.5%), 0.28t of oxalic acid (oxalic acid content≥99%), and 0.12t of citric acid (citric acid content≥99%) through the delivery device....

specific Embodiment 3

[0050] Specific embodiment 3: A certain sludge deep dewatering project has two diaphragm plate and frame filter presses, the filter plate size of the plate and frame filter press is 1.5m*1.5m, and there are 110 filter plates. After using for a period of time, the filter cloth has obvious scale, the filter cloth hardens, the feed pressure rises rapidly to above 1.0MPa and the injection volume decreases obviously, indicating that the filter cloth of the table frame needs to be cleaned. After testing, the scale components were 31.6% calcium carbonate, 17.1% calcium hydroxide, 6.8% magnesium hydroxide, 22.8% iron hydroxide, 13.5% magnesium hydrogen phosphate, and 8.2% with unknown ingredients. The PLC controller starts the acid mixing process, and the acid liquid tank is injected with 0.32t of acetic acid (acetic acid content≥99.5%), 0.24t of oxalic acid (oxalic acid content≥99%), and 0.08t of citric acid (citric acid content≥99%) through the delivery device. After diluting with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com