A six-wheeled mobile robot with three-section body

A three-stage, body technology, applied in the field of robots, can solve the problems of insufficient flexibility of the mobile mechanism and single movement mode, and achieve the effect of various movement modes, wide application range and high movement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific implementation mode one: as Figure 1 to Figure 4 As shown, this embodiment describes a six-wheeled mobile robot with a three-segment body, including a three-segment body, a front body articulation joint 4, a rear body articulation joint 5, and six legs. The three-segment body is respectively It is the front body 1, the middle body 2 and the rear body 3, and the six legs are respectively the left front leg 6, the left middle leg 7, the left rear leg 8, the right front leg 9, the right middle leg 10, and the right rear leg 11; The above six legs have the same structure and are all wheel-foot composite legs. The middle part of the rear end of the front body 1 is rotationally connected with the middle part of the front end of the middle body 2 through the hinge joint 4 of the front body. Body articulation joint 5 is rotationally connected with the middle part of the front end of rear body 3 , said front body 1 rotates left and right around the vertical axis of fro...

specific Embodiment approach 2

[0023] Specific implementation mode two: as figure 1 , image 3 , Figure 5 and Figure 6 As shown in the first embodiment, a six-wheeled mobile robot with three sections of the body, the left front end of the front body 1 is fixed with a left front connecting ear 41, and the left front leg 6 is connected to the left front of the front body 1. The connecting ear 41 is rotationally connected, and the right front end of the front body 1 is fixed with a right front connecting ear 42, and the right front leg 9 is rotationally connected with the right front connecting ear 42 of the front body 1;

[0024] The middle part of the left side wall of the middle body 2 is fixed with a left middle connecting ear 43, the left middle leg 7 is rotationally connected with the left middle connecting ear 43 of the middle body 2, and the middle part of the right side wall of the middle body 2 is fixed with a right middle connecting ear. Ear 44, the right middle leg 10 is rotationally connected...

specific Embodiment approach 3

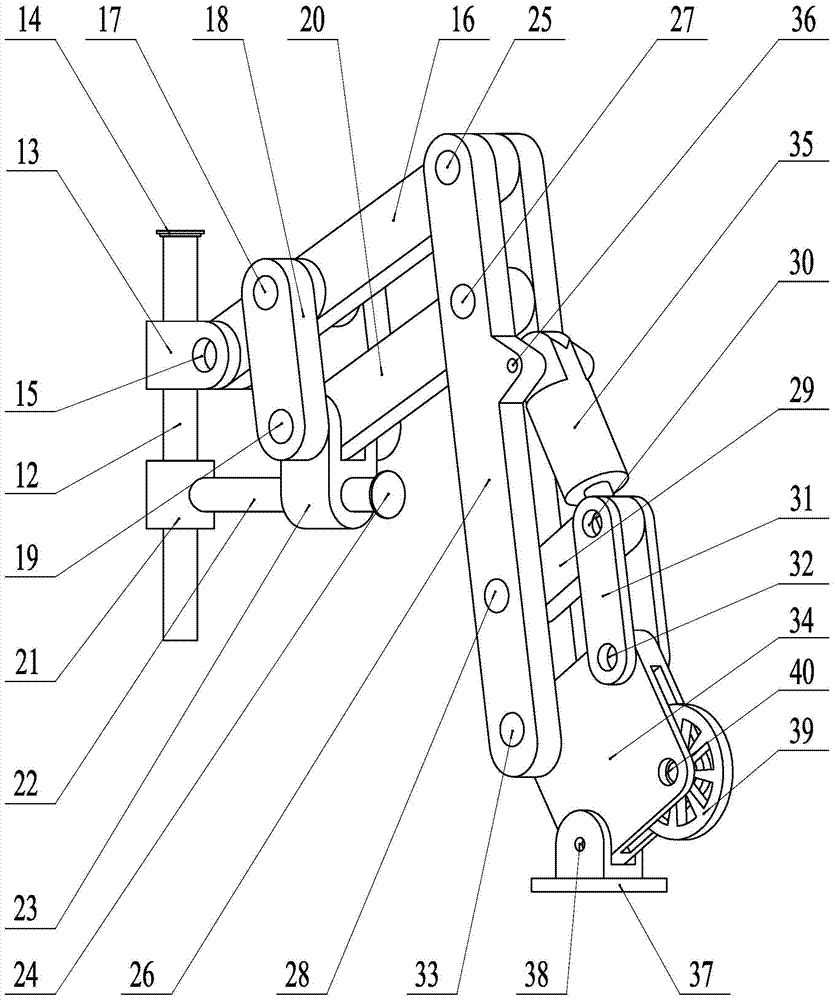

[0026] Specific implementation mode three: as Figure 1 to Figure 6 As shown, the six-wheeled mobile robot with three sections of the body described in the second embodiment, the six legs have the same structure, including a pin shaft 12, a slider 13, a limit stop 14, Joint one 15, connecting rod one 16, joint two 17, connecting rod two 18, joint three 19, connecting rod three 20, joint four 21, pin two 22, slider two 23, limit block two 24, joint five 25. Connecting rod four 26, joint six 27, joint seven 28, connecting rod five 29, joint eight 30, connecting rod six 31, joint nine 32, joint ten 33, wheel foot conversion plate 34, linear drive 35, joint eleven 36. Foot end 37, joint 12 38, wheel 39 and joint 13 40;

[0027]The pin one 12 is vertically arranged, the joint four 21 is rotatably mounted on the pin one 12 (that is, the joint four 21 can rotate around the pin one 12), and the slider one 13 is slidingly sleeved on the pin On the shaft one 12 (that is, the slide blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com