Rail transit train wheel diameter calibrating method

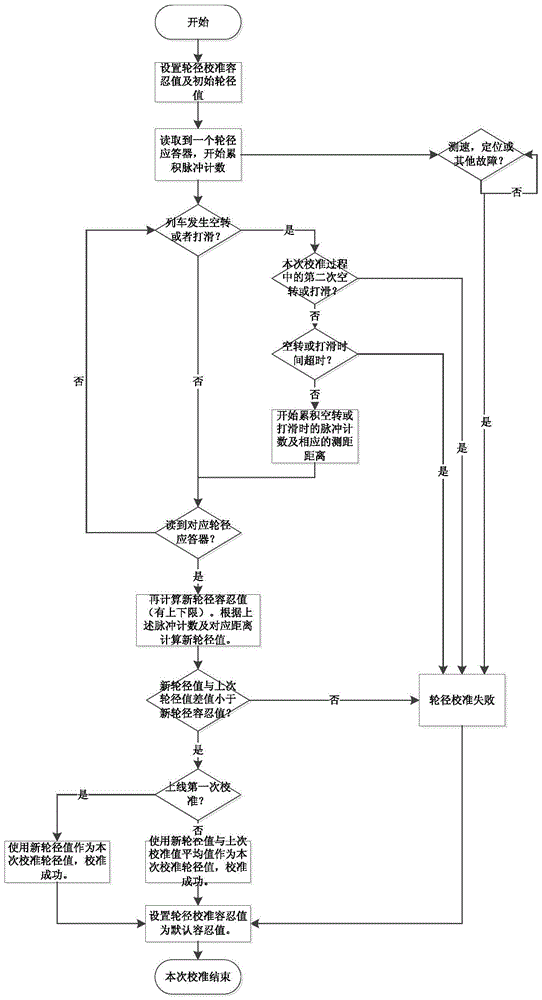

A technology of rail transit train and calibration method, which is applied in the field of rail transit train wheel diameter calibration, can solve the problems of insufficient availability, safety risks, errors in accumulated moving distance, etc., and achieves the algorithm covering a wide range of scenarios and ranges, safe usability, and accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The rail transit train wheel diameter calibration method provided by the present invention includes: selecting multiple pairs of transponders in the transponder database as the wheel diameter calibration transponder pair, and the distance between each pair as the wheel diameter calibration transponder pair is preferably 100 meters to 100 meters. 150 meters, the balise selected as the wheel diameter calibration balise pair in this embodiment is preferably set on a track section with good condition on the non-slope track; the actual distance between these wheel diameter calibration balise pairs is stored in the response after accurate measurement server database. The rail transit train passes all the wheel diameter calibration balise pairs at the same stable speed Speed, and the distance between a certain wheel diameter calibration balise pair is S balis = 100 meters, the initial value of wheel diameter is D 0 , after the pair of wheel diameter calibration transponders, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com