Wheel sensor calibration system and control method thereof

A wheel sensor and calibration system technology, which is applied in the field of wheel sensor calibration system and its control, can solve the problems of non-displacement installation, errors and misactivation in operation links, etc., and achieves the effect of avoiding misactivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

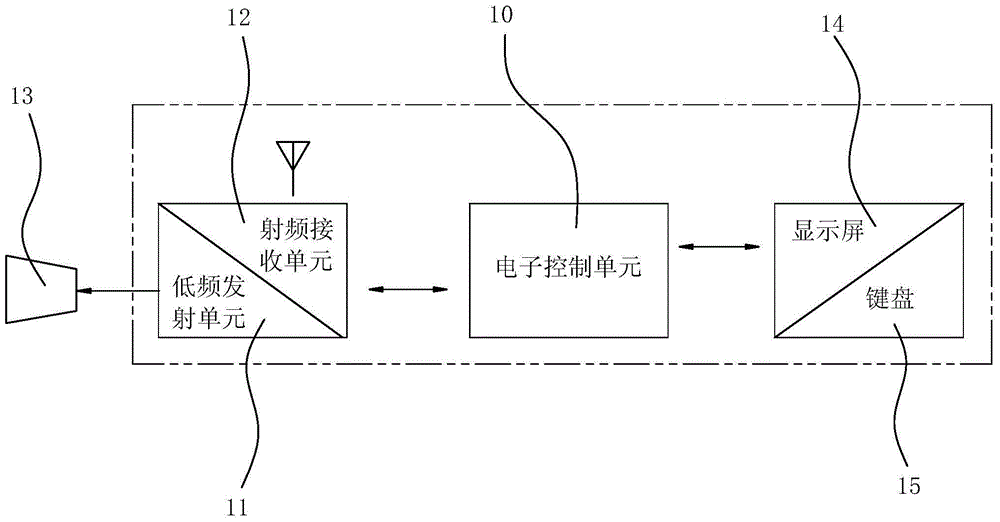

[0016] Such as figure 1 As shown, a wheel sensor calibration system includes an electronic control unit 10, a low-frequency signal transmitting unit 11, and a radio-frequency signal receiving unit 12. The electronic control unit 10 generates a trigger signal, which is transmitted by the low-frequency signal transmitting unit 11 through a directional The antenna 13 wirelessly sends to the target wheel sensor, and the target wheel sensor will send a response signal containing the sensor ID identification code after receiving the trigger signal, and the radio frequency signal receiving unit 12 receives the response signal and transmits the response signal to the electronic control Unit 10.

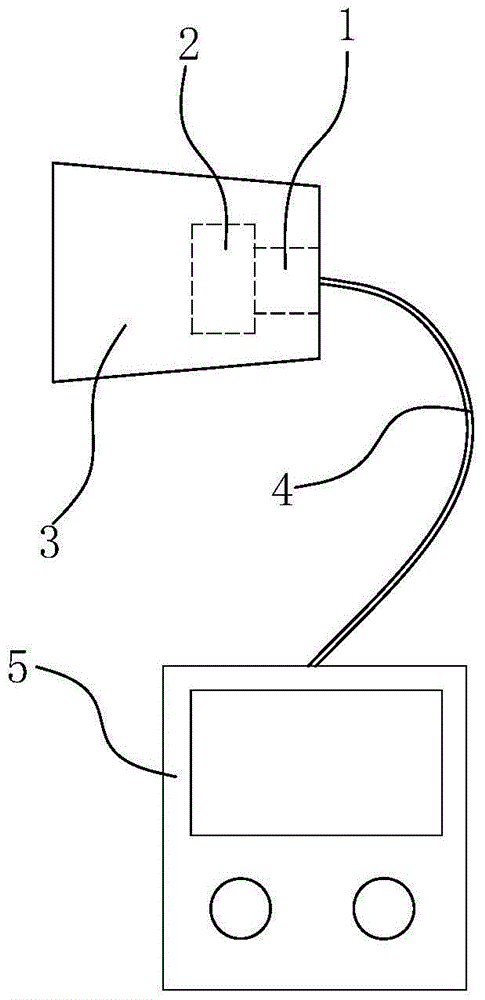

[0017] Such as figure 2 As shown, the directional transmission antenna 13 includes an excitation unit 1, an antenna oscillator 2 and a cluster cover 3, and the excitation unit 1 and the antenna oscillator 2 are installed in the cluster cover 3, and the cluster cover 3 is made of high magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com