Cooling system for surface high-glossiness and leveling treatment of continuous fiber impregnating belt

A continuous fiber and cooling system technology, applied in the field of cooling systems, can solve the problems of equipment layout space waste, inconvenient operation and maintenance, etc., and achieve the effects of convenient operation, high equipment maintenance efficiency, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

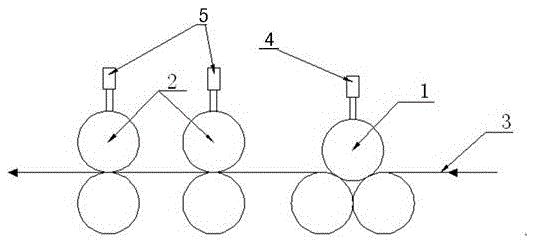

[0013] Depend on figure 1 It can be seen that a cooling system for a continuous fiber impregnated belt with a high-gloss smooth surface consists of a set of product-shaped three-rollers 1, two sets of cooling counter-pressure rollers 2, a continuous fiber impregnated belt 3, cylinder I4 and cylinder II5, and a set of product The three-rollers 1 in the font shape and the upper rollers of the two pairs of cooling counter-pressing rollers 2 are respectively connected with independent air cylinders I4 and II5. The cooling circulation system controls the temperature of the cooling medium; the continuous fiber impregnated belt 3 enters a set of three-shaped three-rollers 1, and the upper roll of the three-roller 1 is pressed downward by the cylinder I4 to press the two lower rolls to make the continuous fiber The impregnated belt 3 forms a wrap angle and generates friction, and then enters the two sets of cooling counter-pressing rollers 2. Under the action of the cylinder II5, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com