A linear robotic arm 3D printer

A technology of 3D printers and robotic arms, applied in 3D object support structures, manufacturing tools, processing drive devices, etc., can solve the problems that restrict the flexible use of linear robotic arm 3D printers, the impact of size and structure, and the practical limitations of 3D printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

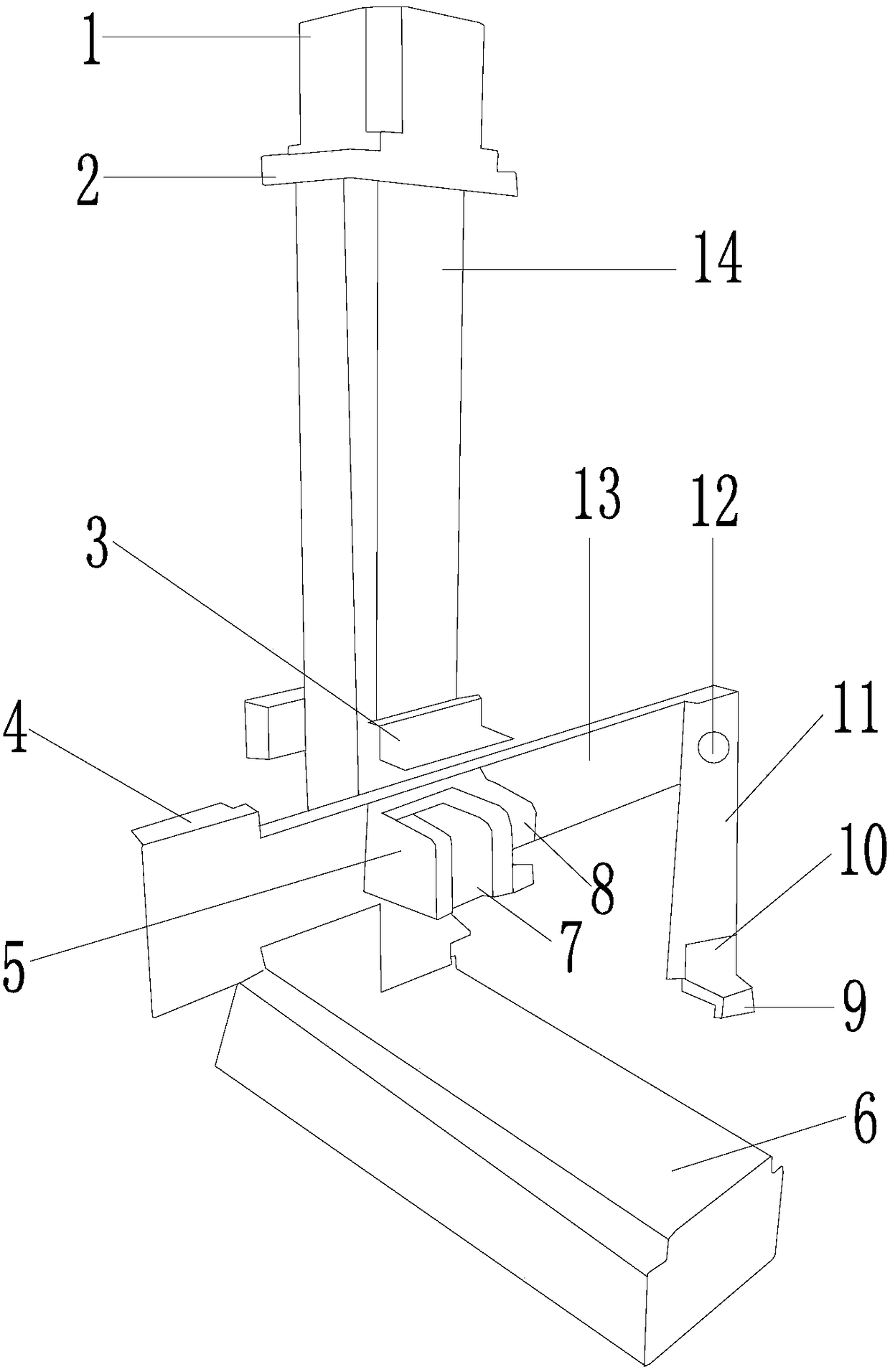

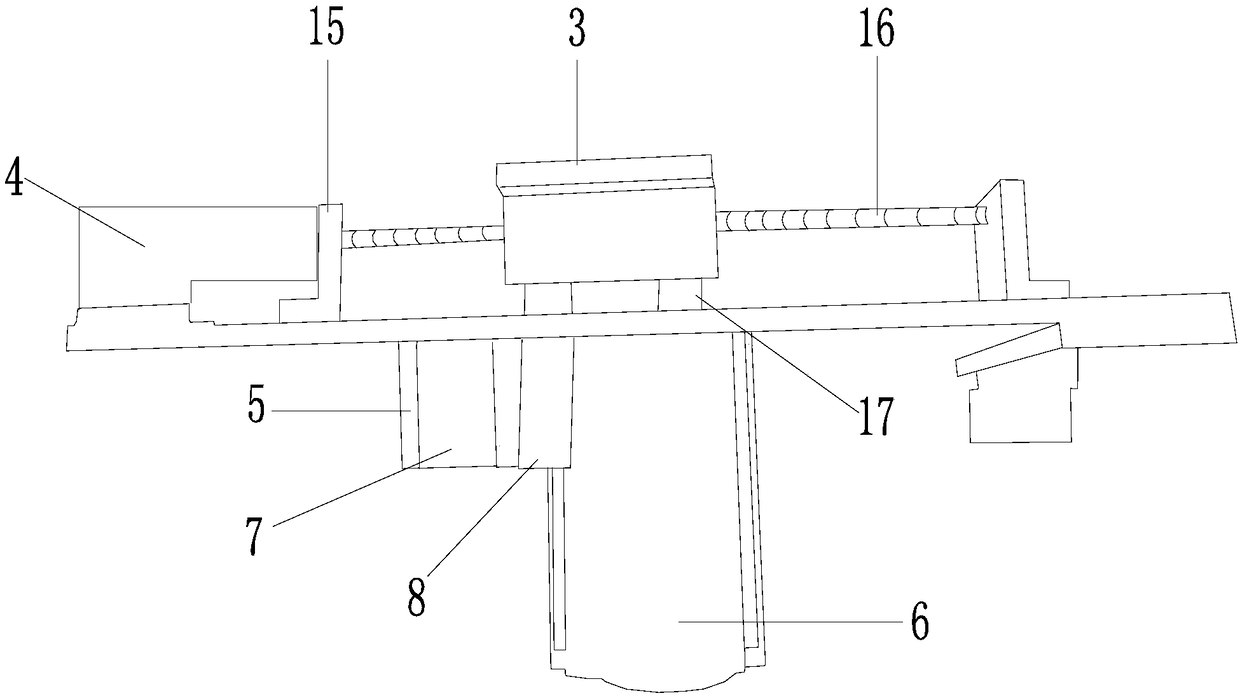

[0022] Such as Figure 1-2 As shown, a linear manipulator 3D printer according to an embodiment of the present invention includes: a Y-axis slide rail 6 , a Z-axis slide rail 14 , and an X-axis arm 13 . Wherein, both sides of the upper part of the Y-axis slide rail 6 are provided with slideways, the Z-axis slide rail 14 falls on the upper part of the Y-axis slide rail 6, and the tracks on both sides of the bottom end of the Z-axis slide rail 14 are located in the slideways. The Z-axis slide block 3 running up and down is installed on the front of the Z-axis slide rail 14 , and the X-axis arm 13 is fixedly connected with the Z-axis slide block 3 . The surface of one end of the X-axis arm 13 is equipped with a rotating arm 11 that can rotate 360°, and a print head 9 is installed at the front end of the rotating arm 11 . 3D printing with a robotic arm is no longer limited to printing on a narrow printing platform, it can work in an open manner, and can be used on any ground or w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com